Efficient SCR (selective catalytic reduction) denitrification reactor

A denitrification reactor and reactor technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve problems affecting flow field distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0059] Specific embodiments of the present invention are as follows:

[0060] (1) Rectifier parameters

[0061] H1 Range: 300mm~600mm

[0062] H2 range: 100mm ~ 150mm

[0063] H5 range: 100mm ~ 400mm

[0064] H6 range: 75 ~ 150mm

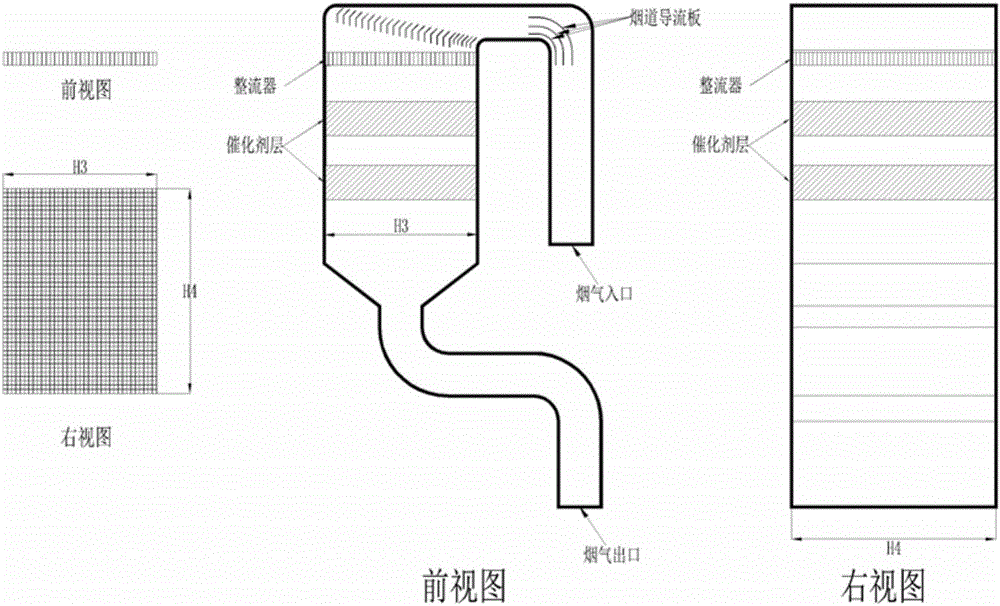

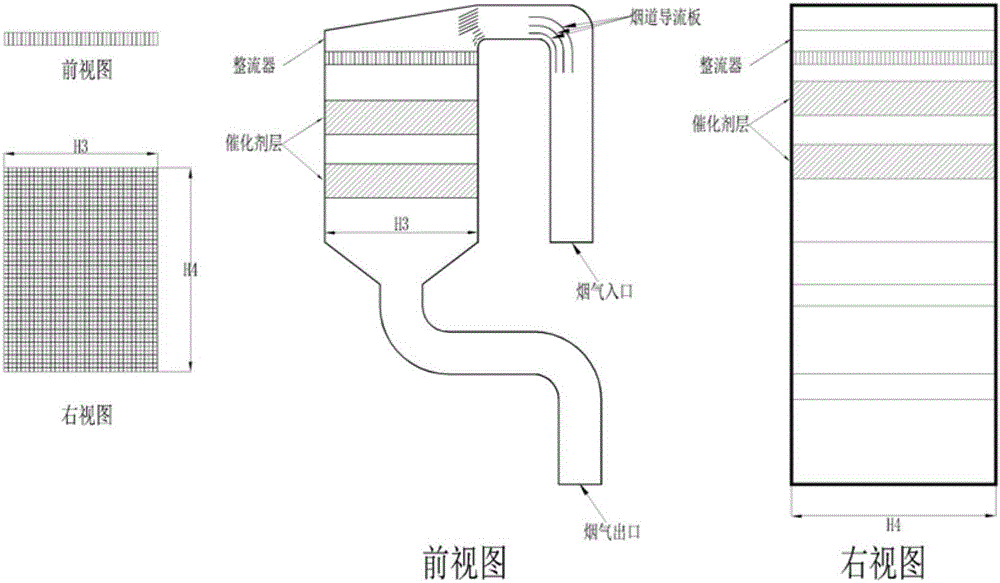

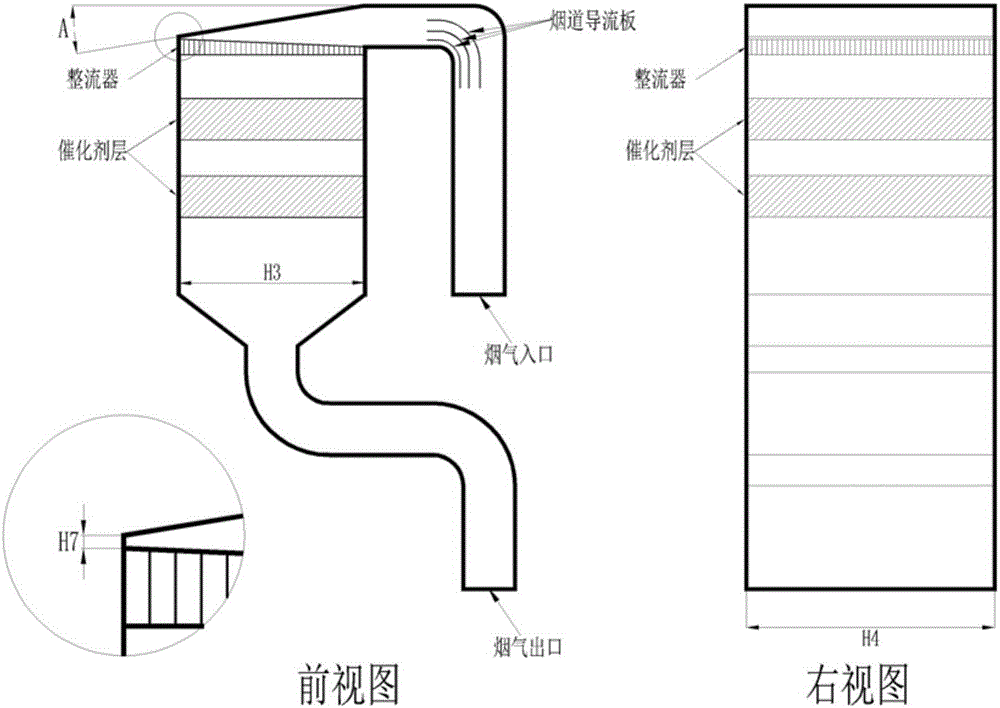

[0065] Flue gas volume = cross-sectional area, that is, the product of H3 and H4 and the cross-sectional gas flow rate. H3 is generally smaller than H4, which is the work of the basic designer of the SCR reactor.

[0066] (2) Reactor parameters

[0067] The gas velocity in the cross-section of the reactor should be controlled below 6m / s.

[0068] The included angle A between the top plate of the reactor and the horizontal direction ranges from 9° to 20°.

[0069] There is no limit to the amount of gas handled.

[0070] (3) Positional relationship between rectifier and reactor

[0071] The apex 4 of the rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com