Catalyst for synthesis of indoxacarb intermediate and preparation method thereof

The technology of a catalyst and an intermediate is applied in the field of a catalyst for synthesizing an indoxacarb intermediate and its preparation, which can solve the problems of slow reaction speed, difficult to apply mechanically, and dechlorination, etc., to reduce the rate of activity decline, save costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

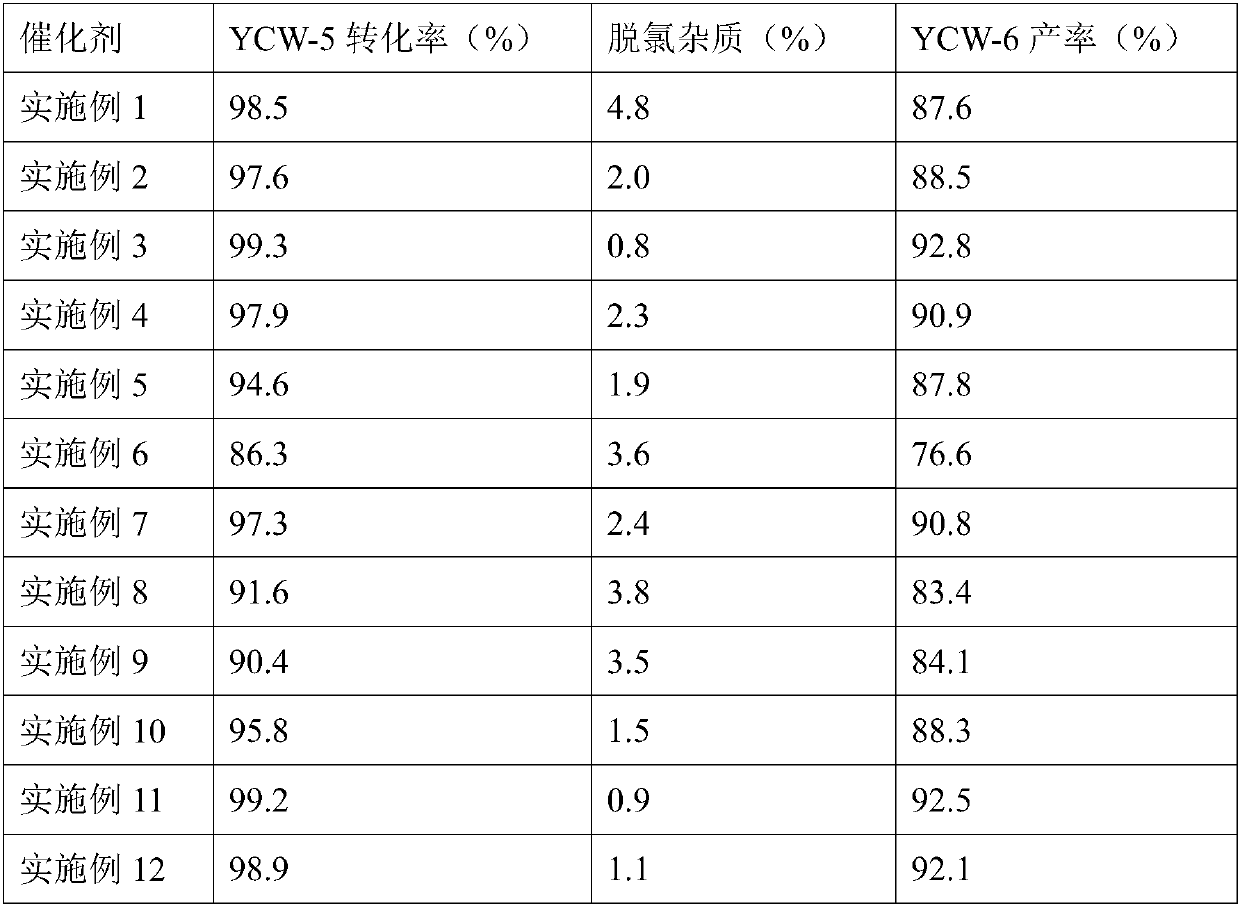

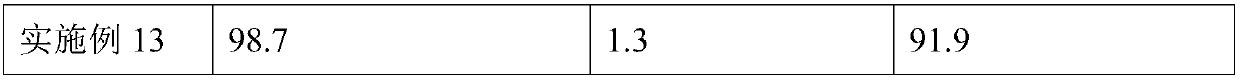

Examples

Embodiment 1

[0016] Step 1, the activated carbon is heated and refluxed with HNO3 with a mass concentration of 5% at a temperature of 80° C. for 4 hours, and then the activated carbon after heating and reflux is washed with deionized water to neutrality;

[0017] Step 2, prepare the activated carbon after washing in step 1 into a slurry, slowly add palladium salt aqueous solution with corresponding palladium quality dropwise according to the palladium loading capacity of 10%, fully stir evenly; immerse for 8h, adjust the pH value of the solution with sodium hydroxide solution to 10. Filter, wash the filter cake with deionized water until it is neutral; then prepare the filter cake with deionized water to prepare the liquid, and perform reduction according to the molar ratio of formic acid and palladium as the reducing agent of 3:1, filter, and wash with deionized water To neutrality, the palladium carbon precursor catalyst is obtained.

Embodiment 2

[0019] In a stainless steel autoclave with a volume of 500 mL, add 20 g of the palladium-carbon precursor catalyst prepared in Example 1, 1 mL of ethylenediamine, and 200 mL of methanol, control the temperature at 30 ° C, fill with hydrogen to a pressure of 0.5 MPa, and start stirring , reacted for 8h, cooled down, washed with 200mL methanol, and filtered to obtain the aminated palladium carbon catalyst.

Embodiment 3

[0021] In a 500mL stainless steel autoclave with a volume of 500mL, add 20g of the palladium-carbon precursor catalyst prepared in Example 1, 1mL of ethylenediamine, and 200mL of methanol, control the temperature at 80°C, fill with hydrogen to a pressure of 0.5MPa, and start stirring. React for 8 hours, cool down, wash with 200 mL of methanol, and filter to obtain the aminated palladium carbon catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com