Drum magnetic separator with crushing and dispersing functions

A drum-type magnetic separator, functional technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., to achieve the effect of reducing the amount of magnetic agglomerated materials and improving the efficiency of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

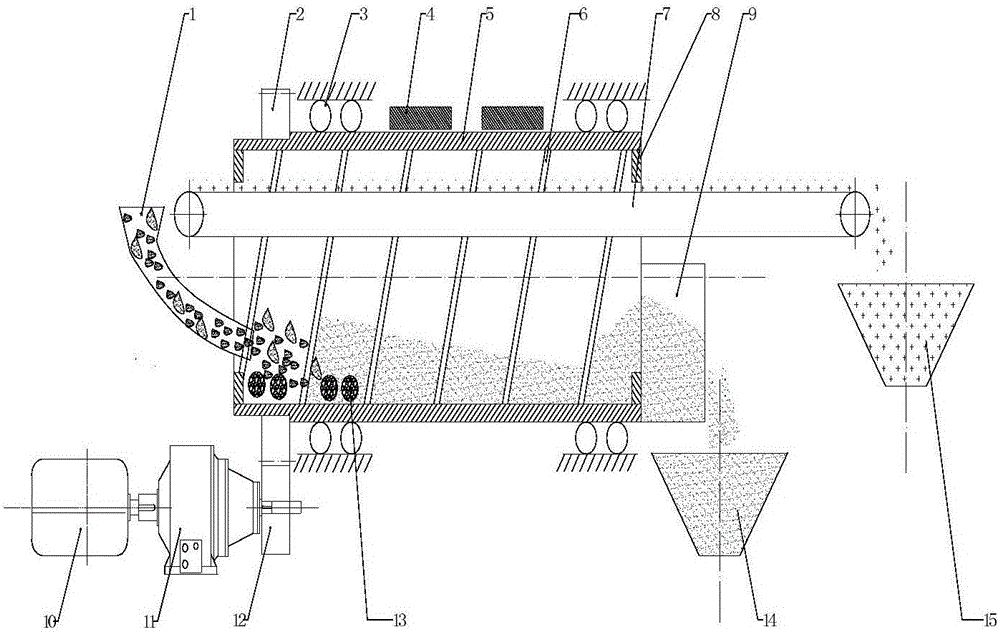

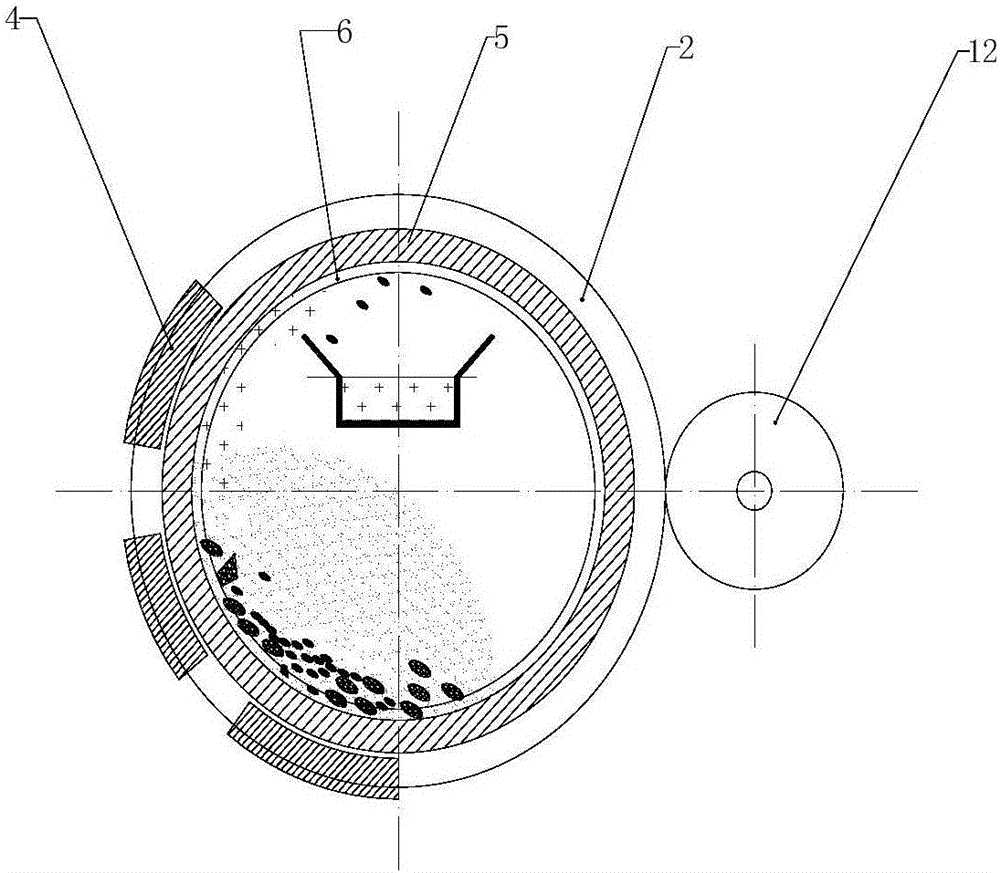

[0033] Such as figure 1 , figure 2 As shown, the pinion 12 is connected with the motor 10 through the reducer 11 to obtain the corresponding torque, the pinion 12 and the bull gear 2 cooperate through a gear pair, the bull gear 2 is fixedly connected with the roller 5, and the support roller 3 is installed on the machine. On the frame, the weight of the roller 5 is supported by the support roller 3, the magnetic system 4 is installed on the frame outside the roller, and constitutes the external magnetic field of the magnetic separator, and the material guide plate 6 is installed on the inner wall of the roller according to the spiral line. To provide the auxiliary force for the materials to move upward and toward the discharge direction, the transmission mechanism 7 passes through the rollers without being connected with the rollers, and mainly transfers the magnetic materials to the magnetic material bin 15 .

[0034] After the material is preliminarily treated by the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com