Composite material for cushion packaging and preparation method thereof

A composite material and buffer packaging technology, applied in the field of polymer materials, can solve the problems of unstable product mechanical properties, uneven mixing and dispersion of raw materials, poor low temperature buffer performance, etc., to improve product strength, tear resistance, and bending resistance. The effect of improved folding performance and transparency, high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

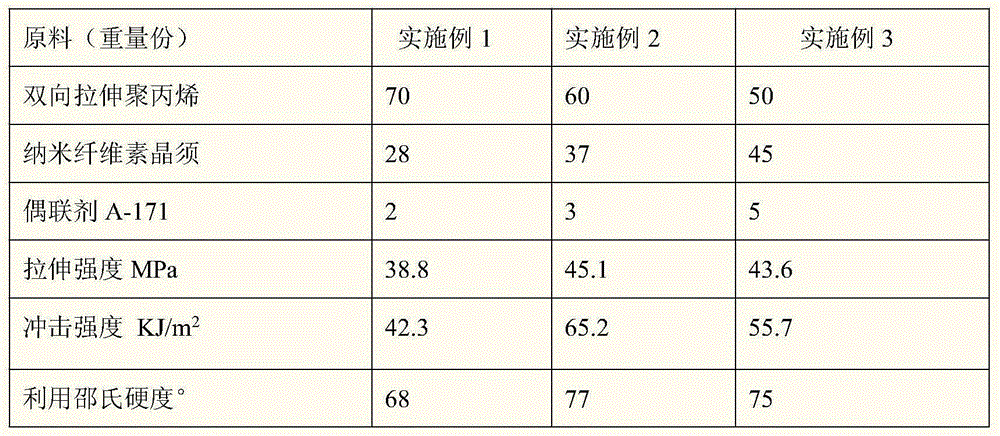

Examples

Embodiment

[0020] (1) First dry the nanocellulose whiskers at 80°C until the moisture reaches 0.5% to obtain component A;

[0021] (2) Place the stretched polypropylene in a high-speed mixer, and add a coupling agent with a formula ratio at the same time, mix at a speed of 300r / min for 5min, and make a mixture B;

[0022] (3) Mix compound A and compound B evenly, extrude on a twin-screw extruder at an extrusion temperature of 180°C, then extrude on a single-screw extruder at a temperature of 180°C, and finally Sheets were formed in a roll calender at a calendering temperature of 130°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com