Multi-stage tobacco carton sorting device and sorting method

A sorting device and a technology for cartons, which are applied in sorting and other directions, can solve problems such as poor production continuity, waste of production time, and low production efficiency, and achieve the effects of reducing load-bearing burden, eliminating noise pollution, and high production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

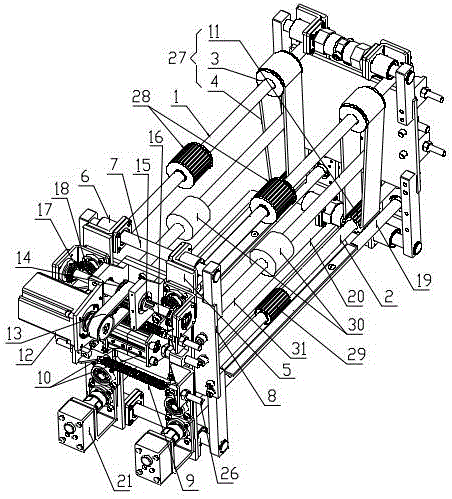

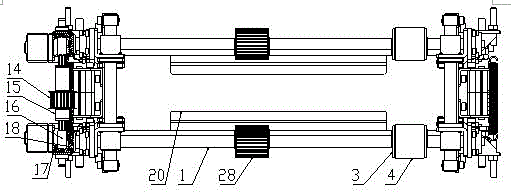

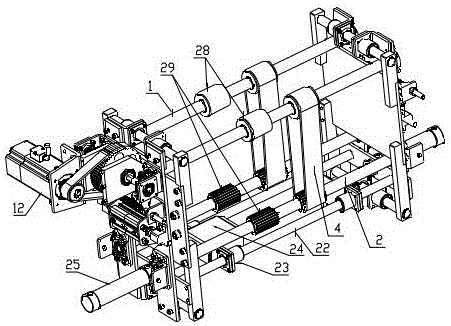

[0022] Example 1. A multi-stage cigarette sorting device, constituted as figure 1 , 2 , 5 and 6, including a drive shaft 1, the drive shaft 1 is provided with a driven shaft 2 below; the drive shaft 1 and driven shaft 2 are connected through a belt transmission mechanism 27; the drive shaft 1 is also connected A primary sorting wheel 28 is provided; a secondary sorting wheel 29 is provided on the driven shaft 2; one end of the driving shaft 1 is connected to the driving device.

[0023] Both ends of the aforementioned drive shaft 1 and driven shaft 2 are connected to the sliding plate 5; the sliding plate 5 is provided with a sliding sleeve 6; the sliding sleeve 6 is connected to the bracket 8 through the guide rail 7; the two sliding plates located at the same end of the driving shaft 1 5 are connected with a spring 9; the support 8 is provided with a stretching plate cylinder 10, and the stretching plate cylinder 10 is connected with the sliding plate 5.

[0024] The afor...

Embodiment 2

[0032] Example 2. A multi-stage cigarette sorting device, constituted as figure 1 , 3 , 4, 5 and 6, including a drive shaft 1, the drive shaft 1 is provided with a driven shaft 2 below; the drive shaft 1 and driven shaft 2 are connected through a belt transmission mechanism 27; the drive shaft 1 There is also a primary sorting wheel 28 on the top; a secondary sorting wheel 29 is provided on the driven shaft 2; one end of the driving shaft 1 is connected to the driving device.

[0033] Both ends of the aforementioned drive shaft 1 and driven shaft 2 are connected to the sliding plate 5; the sliding plate 5 is provided with a sliding sleeve 6; the sliding sleeve 6 is connected to the bracket 8 through the guide rail 7; the two sliding plates located at the same end of the driving shaft 1 5 are connected with a spring 9; the support 8 is provided with a stretching plate cylinder 10, and the stretching plate cylinder 10 is connected with the sliding plate 5.

[0034] The afores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com