Efficient dedusting equipment for PCB circuit board for electronic and scientific development

A technology of PCB circuit boards and dust removal equipment, which is applied in the fields of dust removal, printed circuit, printed circuit manufacturing, etc., and can solve the problems of easy harm to workers' health, easy dust flying around, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

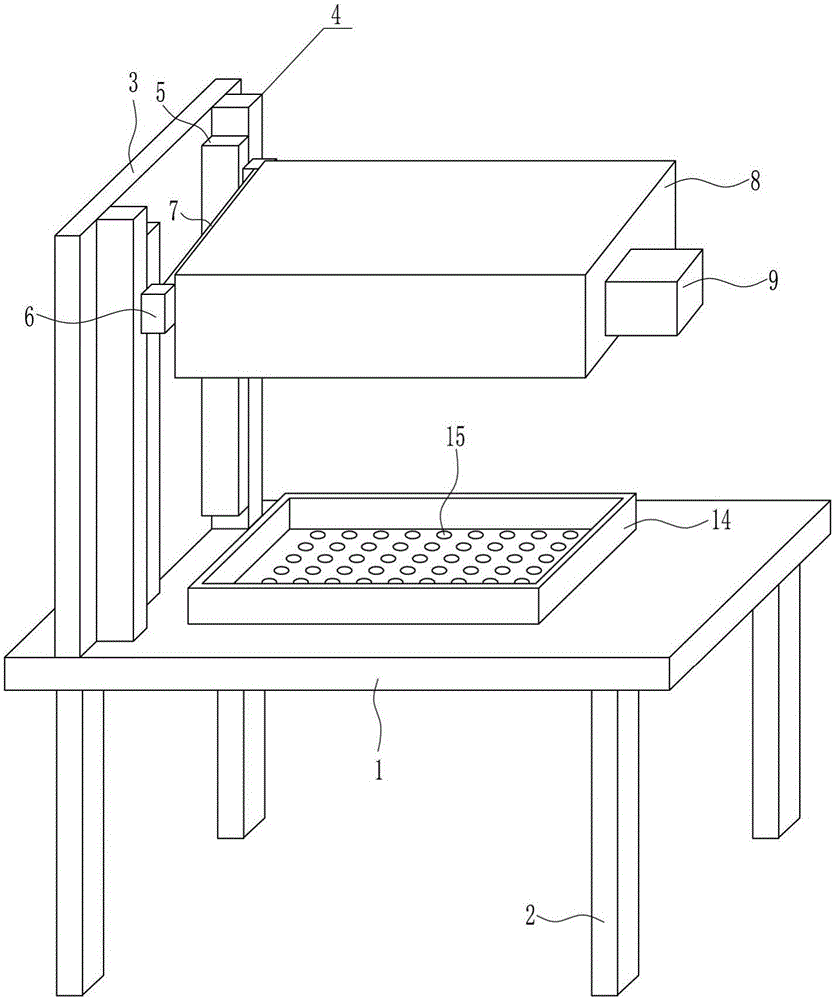

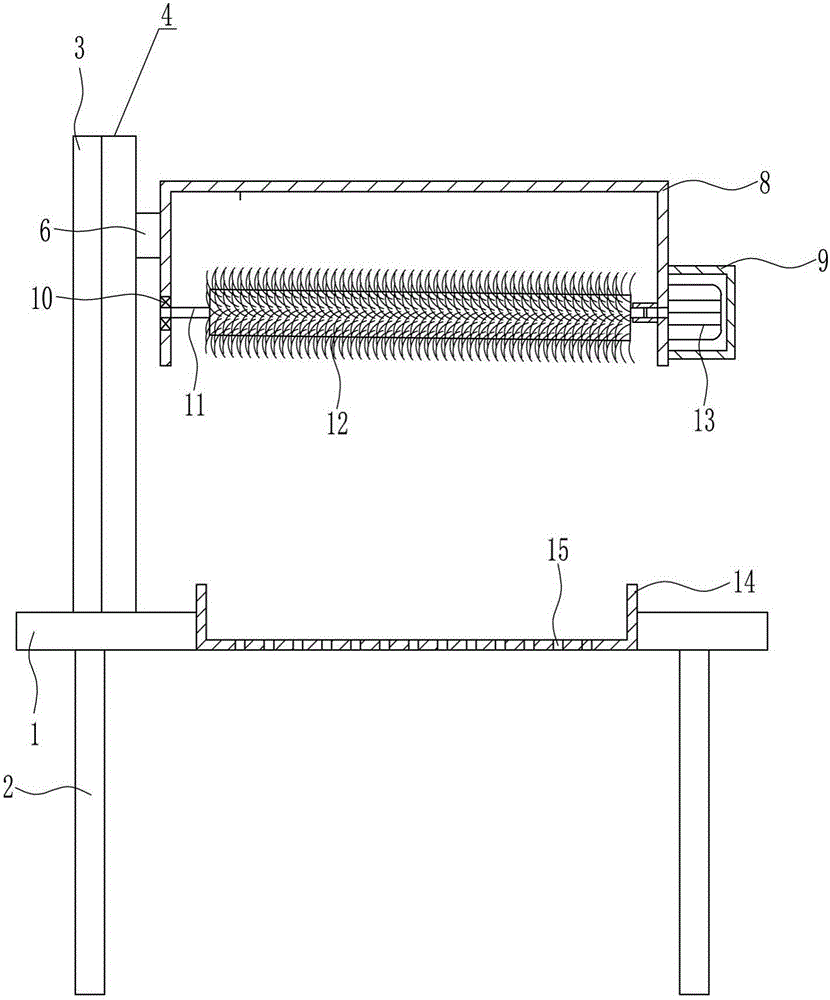

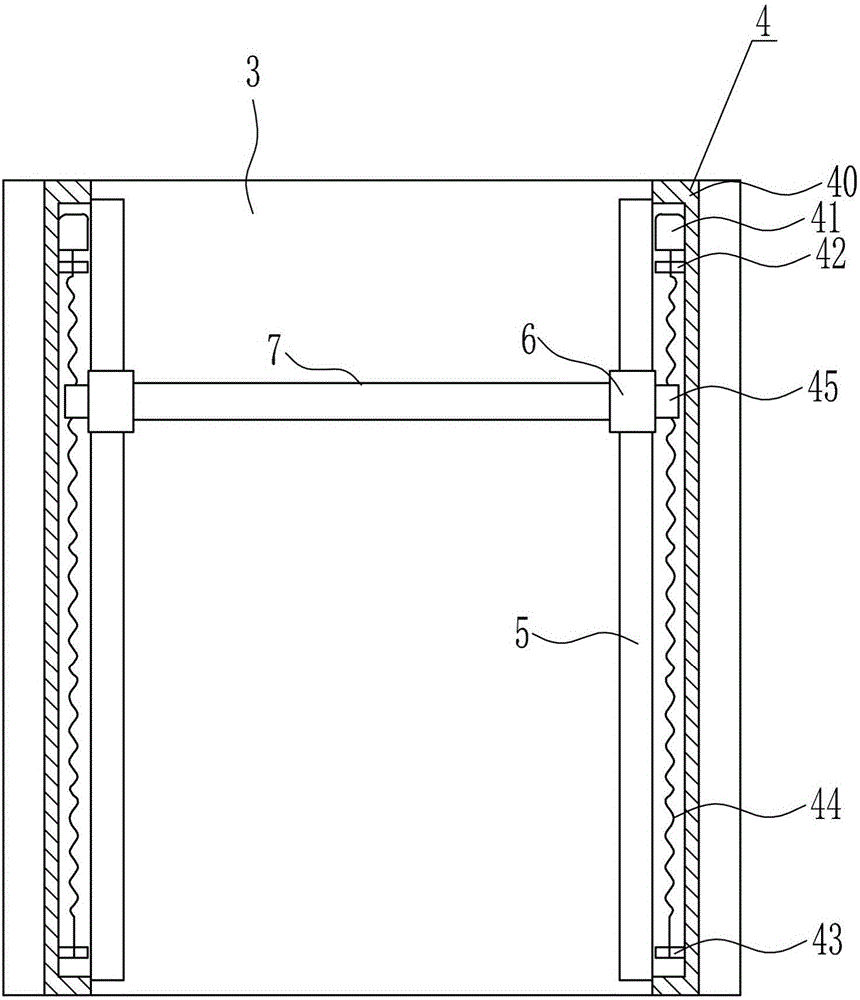

[0036] A kind of high-efficiency dust removal equipment for PCB circuit boards for electronic technology development, such as Figure 1-8 As shown, it includes top plate 1, outrigger 2, left side plate 3, up and down moving mechanism 4, first slide rail 5, first slider 6, connecting plate 7, box body 8, motor box 9, first bearing seat 10. The rotating shaft 11, the rolling brush 12, the first motor 13 and the storage box 14, the bottom of the top plate 1 is provided with the outrigger 2, the left side plate 3 is vertically provided on the left side of the top plate 1, and the left side plate 3 is connected by bolts Connected with the top of the top plate 1, the middle part of the top plate 1 is embedded with a storage box 14, and the bottom of the storage box 14 is evenly spaced with dust outlet holes 15, and the left side plate 3 is equipped with an up and down movement mechanism 4 symmetrically in front and rear on the right side. The left side plate 3 right side between the...

Embodiment 2

[0038] A kind of high-efficiency dust removal equipment for PCB circuit boards for electronic technology development, such as Figure 1-8 As shown, it includes top plate 1, outrigger 2, left side plate 3, up and down moving mechanism 4, first slide rail 5, first slider 6, connecting plate 7, box body 8, motor box 9, first bearing seat 10. The rotating shaft 11, the rolling brush 12, the first motor 13 and the storage box 14, the bottom of the top plate 1 is provided with the outrigger 2, the left side plate 3 is vertically provided on the left side of the top plate 1, and the left side plate 3 is connected by bolts Connected with the top of the top plate 1, the middle part of the top plate 1 is embedded with a storage box 14, and the bottom of the storage box 14 is evenly spaced with dust outlet holes 15, and the left side plate 3 is equipped with an up and down movement mechanism 4 symmetrically in front and rear on the right side. The left side plate 3 right side between the...

Embodiment 3

[0041] A kind of high-efficiency dust removal equipment for PCB circuit boards for electronic technology development, such as Figure 1-8As shown, it includes top plate 1, outrigger 2, left side plate 3, up and down moving mechanism 4, first slide rail 5, first slider 6, connecting plate 7, box body 8, motor box 9, first bearing seat 10. The rotating shaft 11, the rolling brush 12, the first motor 13 and the storage box 14, the bottom of the top plate 1 is provided with the outrigger 2, the left side plate 3 is vertically provided on the left side of the top plate 1, and the left side plate 3 is connected by bolts Connected with the top of the top plate 1, the middle part of the top plate 1 is embedded with a storage box 14, and the bottom of the storage box 14 is evenly spaced with dust outlet holes 15, and the left side plate 3 is equipped with an up and down movement mechanism 4 symmetrically in front and rear on the right side. The left side plate 3 right side between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com