Plate surface microstructure plowing type forming device and forming method

A microstructure and plate technology, applied in the field of mechanical engineering, can solve the problems of easy breakage of thin plate glass, inconsistent filling rate, etc., and achieve the effect of improving forming efficiency and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

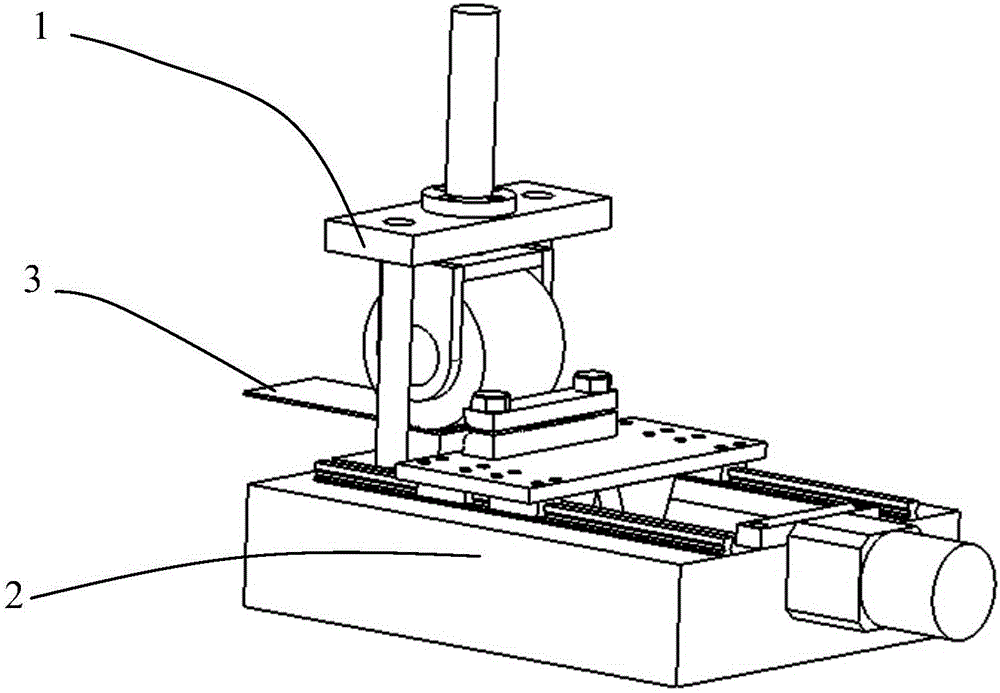

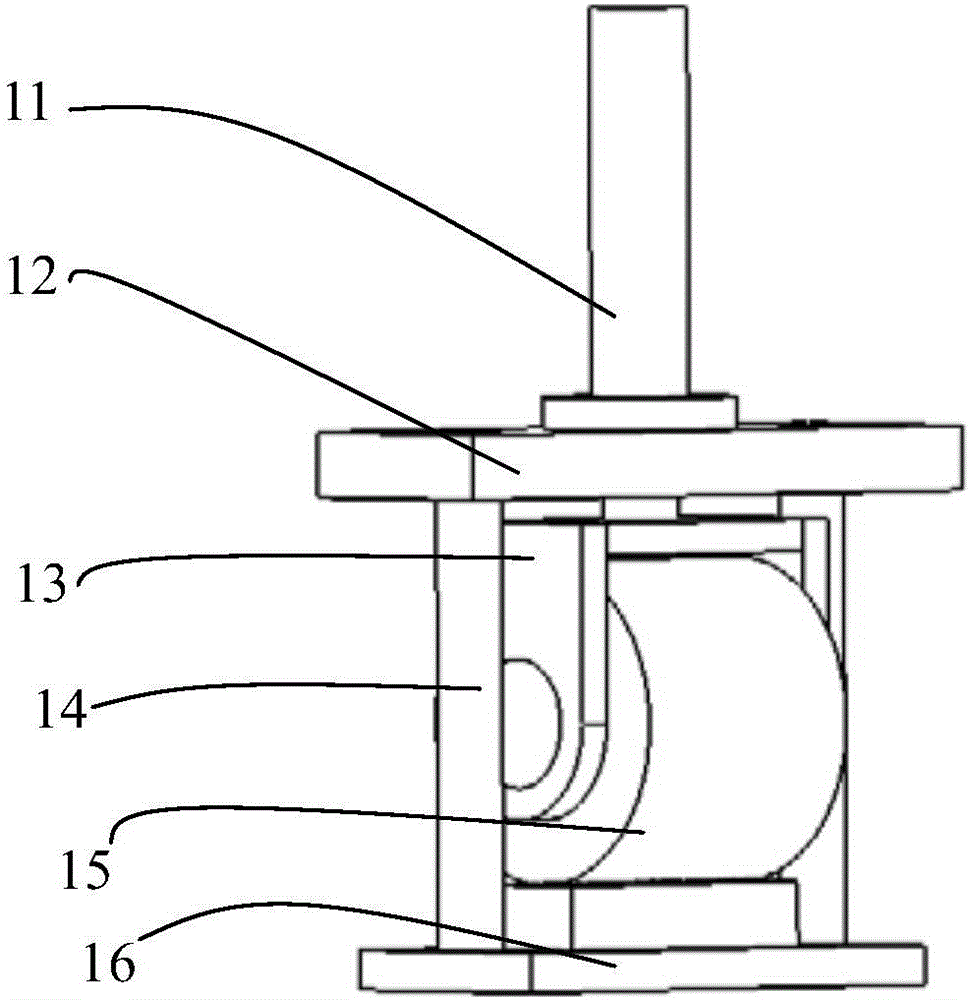

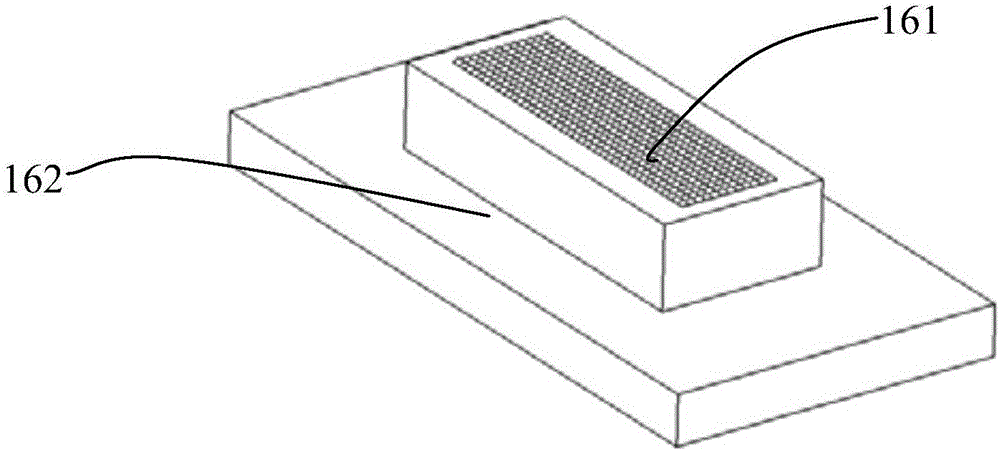

[0035] The embossing assembly 1 is fixedly connected with the top of the plow assembly 2. The structure of the embossing assembly 1 is: the pressure cylinder 11 is assembled on the bearing plate 12, the piston rod of the pressure cylinder 11 is connected with the roller support 13, and the roller 15 Assembled and connected with the roller support 13, the lower part of the bearing plate 12 is fixedly connected with the support column 14, and the microstructure bottom mold 16 is fixedly connected with the lower part of the support column 14; the structure of the plow assembly is: the clamping jaw 21 is fixed through the The jaw 213 is connected with the support plate 23, and the bottom of the support plate 23 is slidingly connected with a group of guide rails 22. The guide rail 22 is fixedly connected to the base 24, the middle part under the support plate is consolidated with the guide seat 25, and the guide seat 25 and the screw rod 26 are threaded. Connection, the screw rod 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com