High-stability simple automatic wire welding machine and welding method thereof

A high-stability, simple technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as fatigue of operators, limited efficiency and yield of connector welding process, complex equipment structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

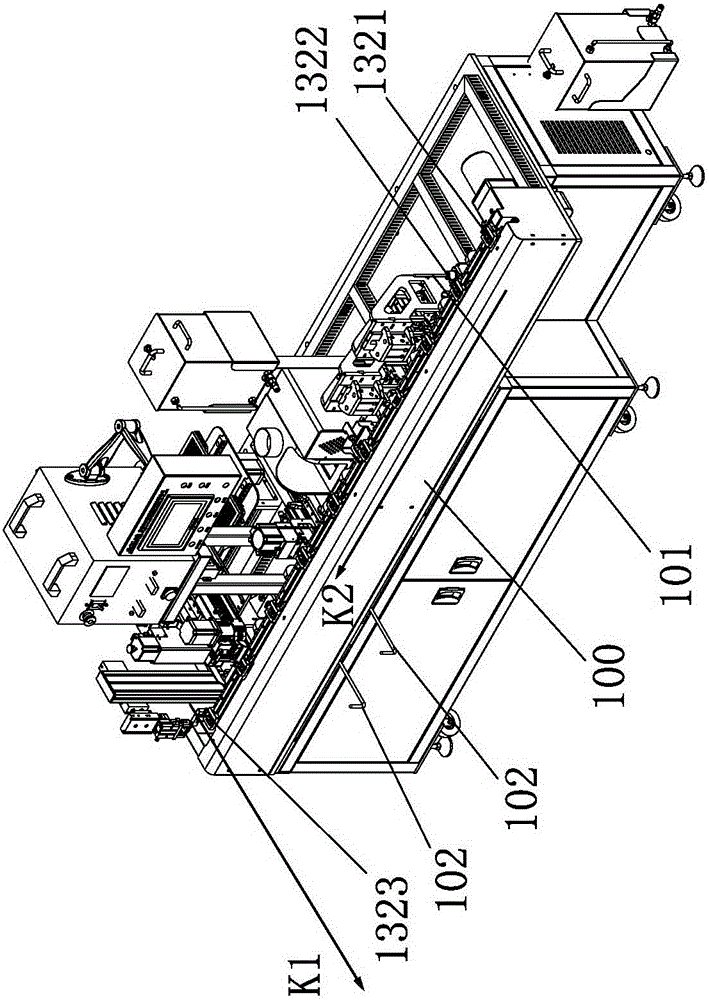

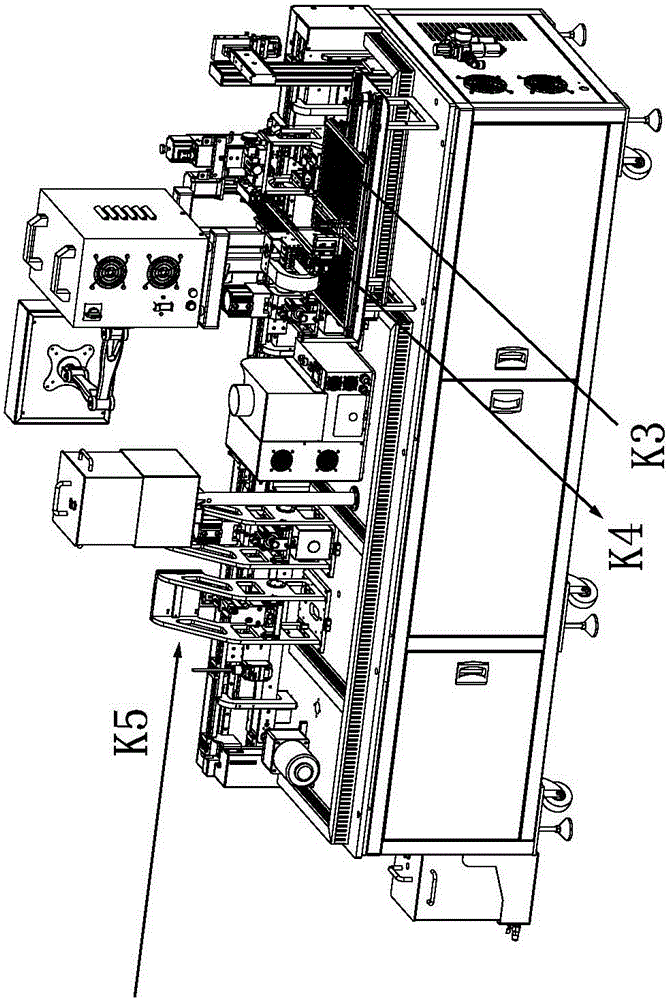

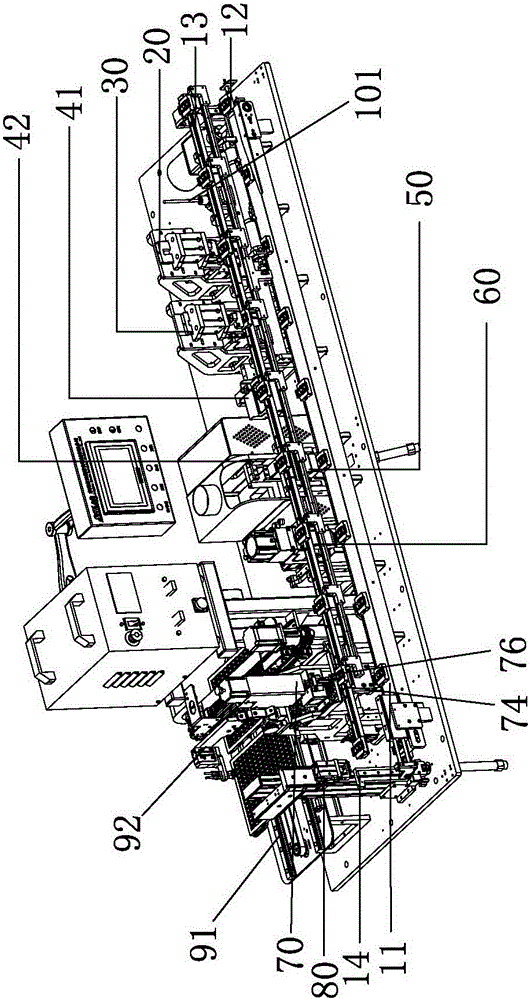

[0087] Please refer to Figure 1 to Figure 18 As shown, it shows the specific structure of the embodiment of the present invention; the automatic wire welding machine is generally suitable for the operation mode of one person and one machine, which has better operation stability, precision and high controllability, and at the same time, The whole device has simple structure and low device cost.

[0088] The automatic wire welding machine includes a frame 100, and the frame is provided with a fixture circulation conveying system; the fixture circulation conveying system includes a lower fixture reflow module 11 and a right fixture lifting module 12 arranged sequentially. , the upper side fixture intermittently toggles the conveying module 13 and the left end fixture lifting module 14, and the left end fixture lifting module 14 is connected to the input side of the lower side fixture return module 11; combined Figure 3 to Figure 6 As shown, the upper clamp intermittent shiftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com