Protective layer cushion block as well as production process and device thereof

A production process and protective layer technology, which is applied in the field of reinforced concrete construction supporting equipment, can solve the problems of heavy weight, impurities, structural strength and size specifications of the protective layer pads that do not meet the specification requirements, and achieve stability and engineering quality. Reliable assembly and precise positioning, light and tough structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The core of the present invention is to provide a protective layer cushion block, which is light and tough in texture, regular in size and high in structural strength; at the same time, it provides a production process for producing the protective layer cushion block and Production equipment.

[0049] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

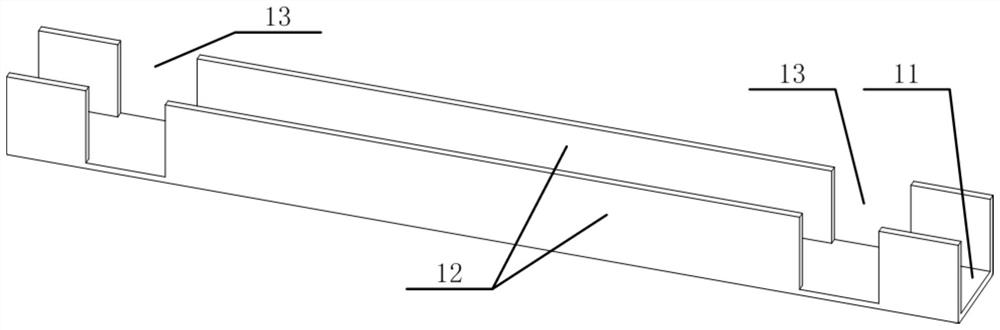

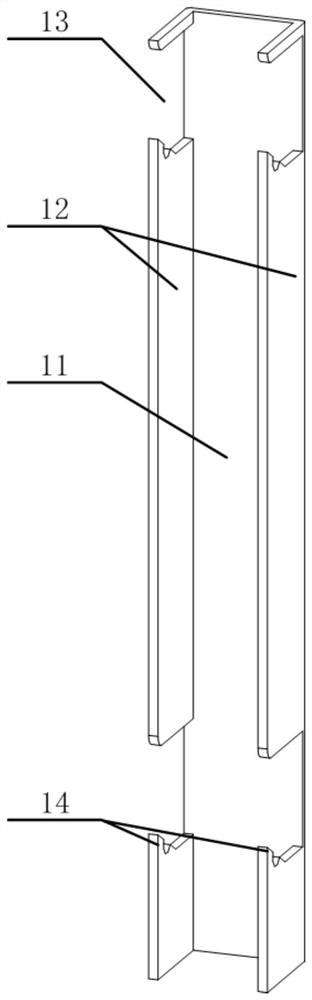

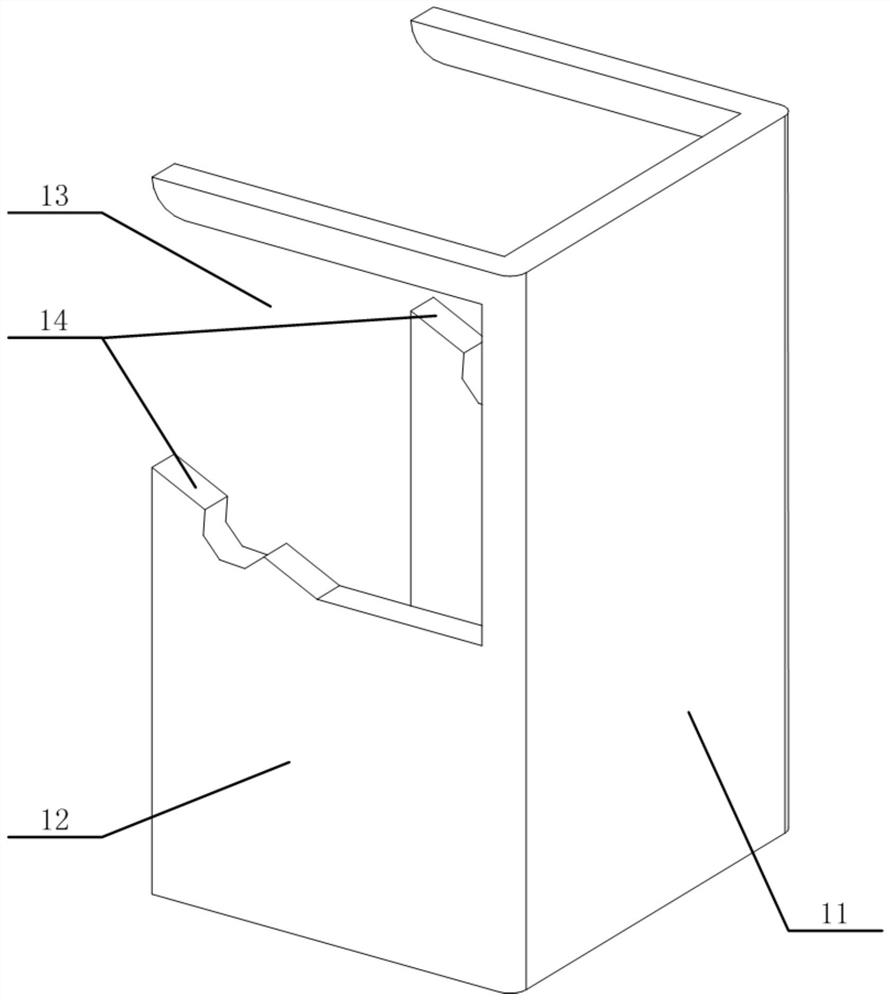

[0050] Please refer to Figure 1 to Figure 3 .

[0051] In a specific embodiment, the protective layer spacer provided by the present invention includes a base plate 11 and side plates 12 symmetrically arranged on both sides of the base plate 11. The base plate 11 and the side plates 12 are an integrated structure formed by pressing steel plates. Card slots 13 for inserting and fitting the steel bars 20 are arranged on the boards 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com