Adjustable-capacity type sand box

An adjustable sand box technology, applied in the field of sand casting, can solve the problems of waste of raw and auxiliary materials, complicated welding and cutting operations, and long transformation cycle, so as to avoid waste of time and cost, improve effective use time, The effect of rapid volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

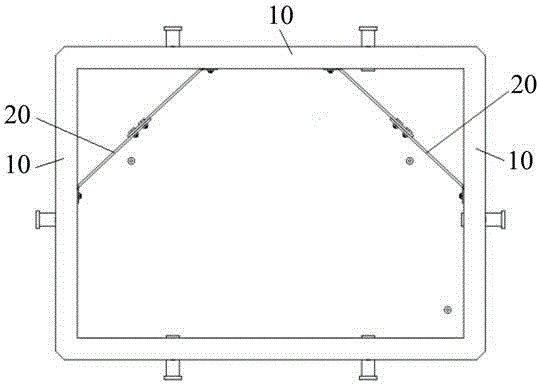

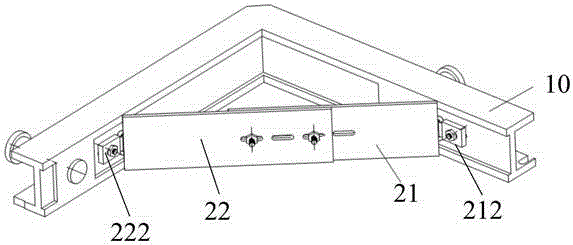

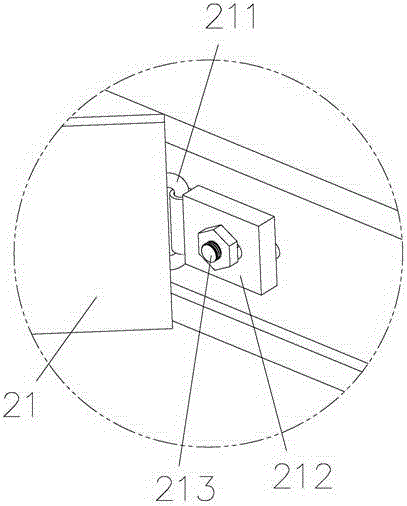

[0018] see Figure 1 to Figure 5 , the embodiment of the present invention provides a volume-adjustable sand box, including a sand box side plate 10 and a movable partition member 20, the corners of the sand box are formed between the adjacent sand box side plates 10, and the movable The movable partition 20 is arranged at the corner of the sand box to isolate the corner of the sand box. The movable partition 20 includes a first partition 21, a second partition 22, and an intermediate connector 23. One end of the first partition 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com