Method for filling solder

A filling method and solder technology, applied in welding equipment, tin feeding devices, metal processing equipment, etc., can solve problems such as affecting the filling effect, and achieve the effect of optimizing the filling effect and reducing dust and water vapor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

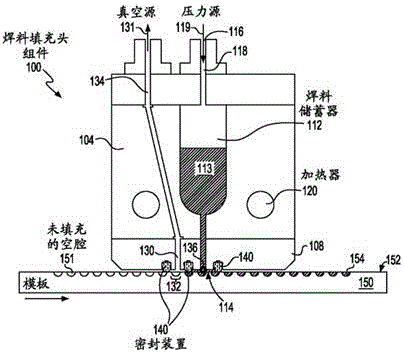

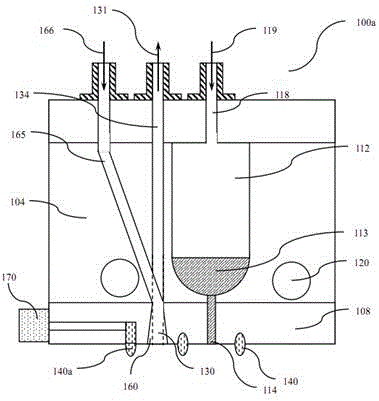

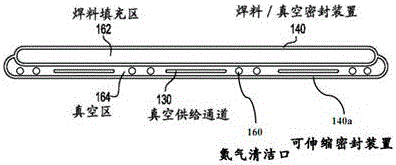

[0021] see figure 2 , the present invention provides a solder filling device 100a, characterized in that it comprises: at least one chamber 112 for holding molten solder 113, said chamber 112 having an outlet 114 for discharging said molten solder; positioned at sealing means 140 on opposite sides of the molten solder 113 outlet; having a vacuum means inlet 130 adjacent to the molten solder outlet 114; positioned on the side of the vacuum means inlet 130 on the side of the sealing means The retractable sealing device 140a constituting the vacuum area; there is also a gas cleaning outlet 160 in the vacuum area, and the gas source 165 communicates with the gas cleaning outlet 160 through a gas tube 166 . During operation, only one of the gas cleaning outlet 160 and the vacuum device inlet 130 can be opened. When the gas cleaning outlet 160 is opened, the cavity contacting the workpiece is cleaned, and the retractable sealing device 140a is in an unsealed state. When the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com