Construction method for curing non-aqueous slurry at normal temperature in blast furnace

A technology of room temperature curing and construction method, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of difficult to control slurry filling height and filling effect, and achieve the effect of improving filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

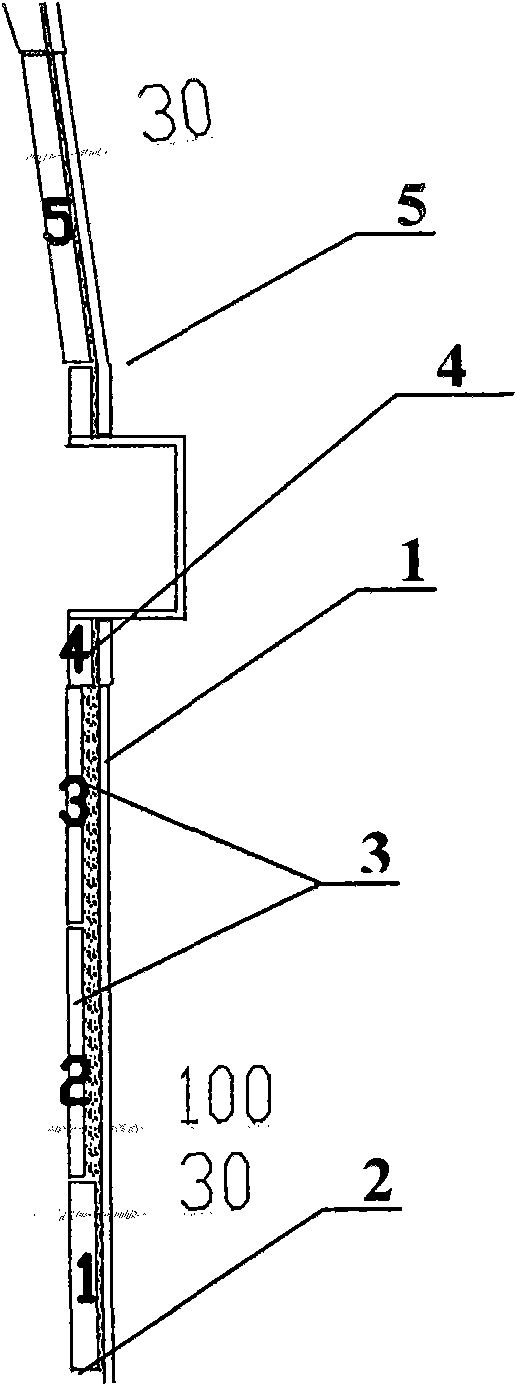

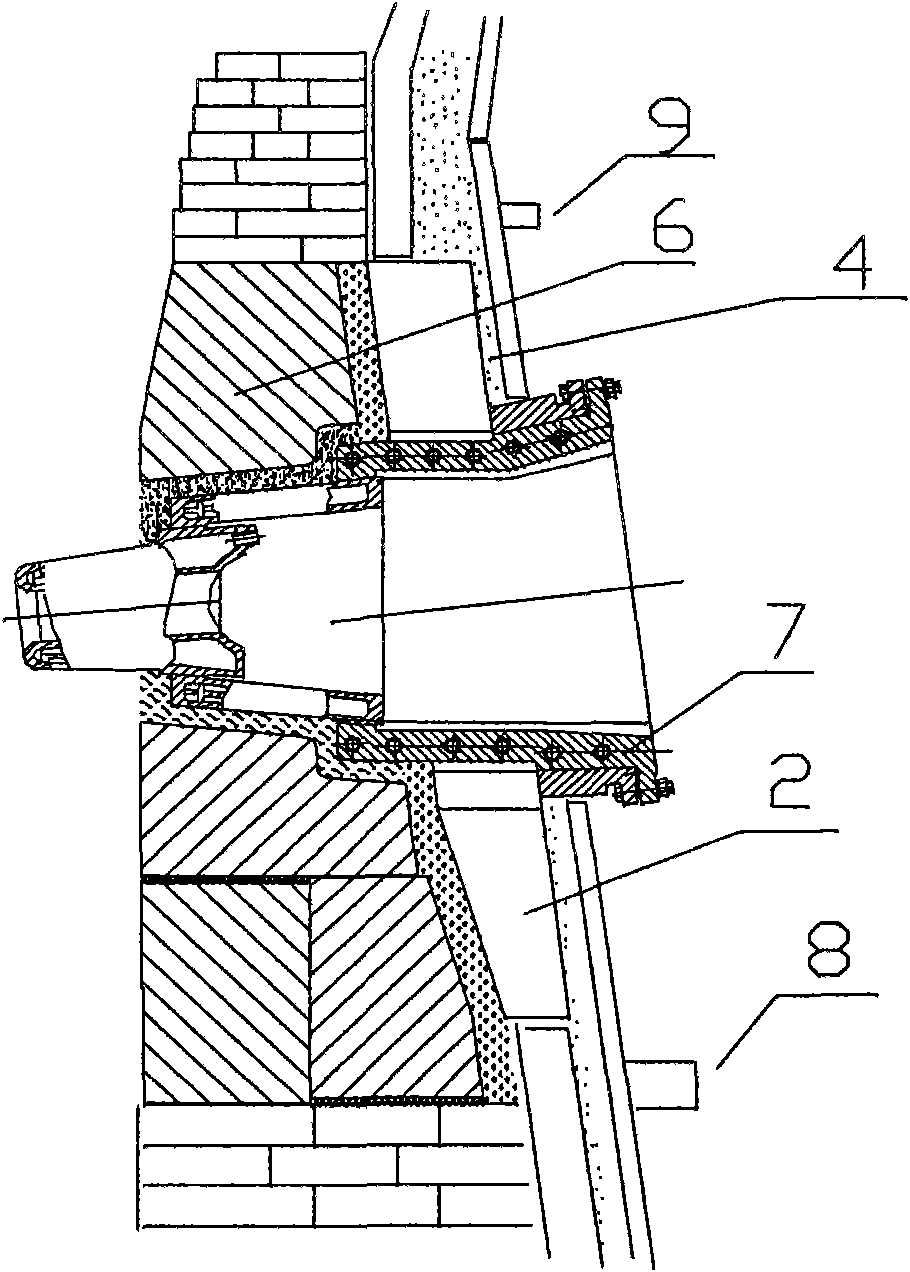

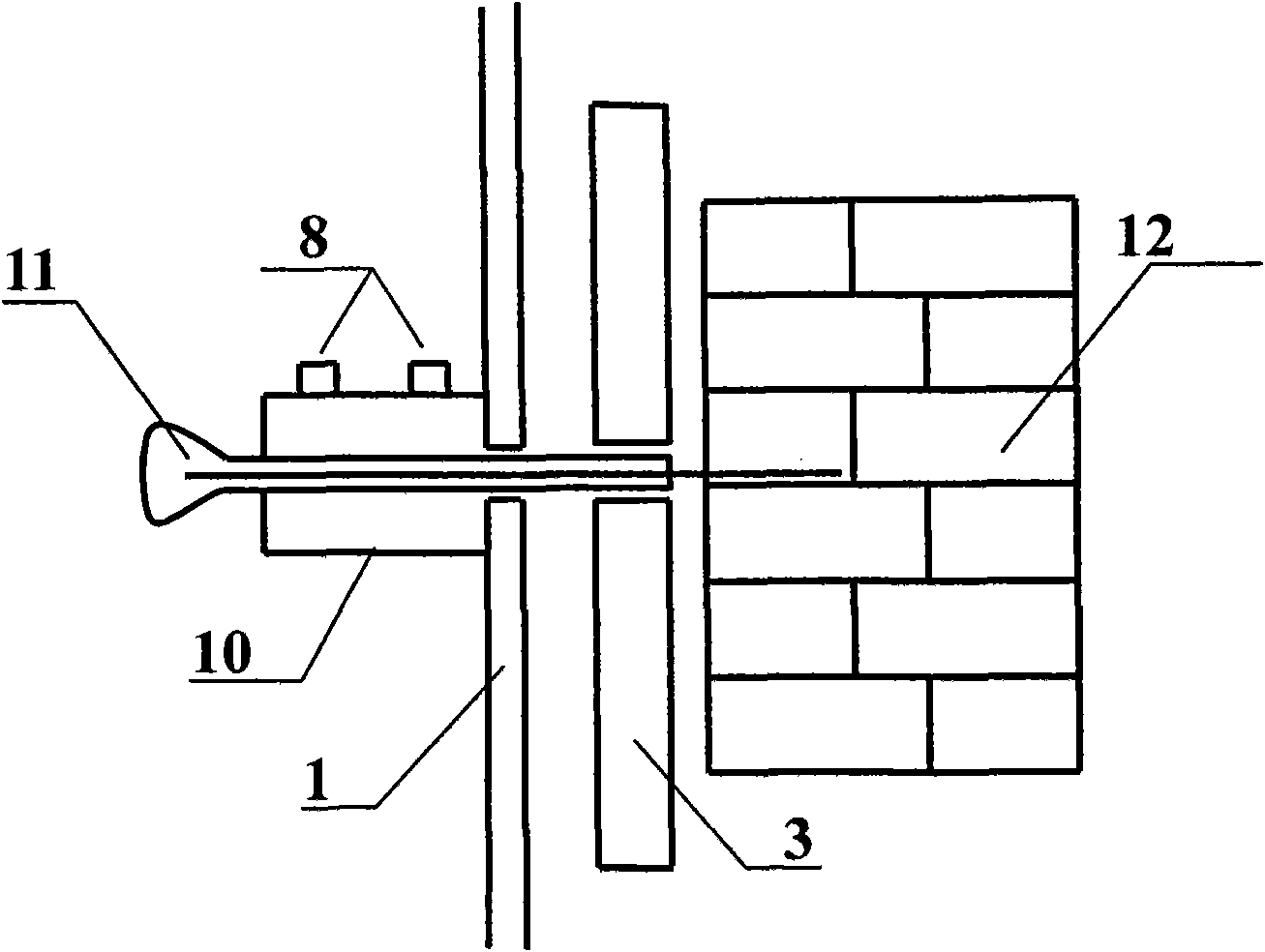

[0018] The first section of Qiangang No. 3 Blast Furnace stave is cast iron stave 2, the second and third sections are copper stave 3, the fourth, fifth and sixth sections are cast iron stave 2, and the taphole 5 in the fourth section of cooling wall, and the large set of tuyeres 6 in the sixth section of cooling wall. The width between the cast iron stave 2 and the furnace skin 1 is about 30mm, the width between the copper stave 3 and the furnace skin 1 is 100mm, and the gap difference between the furnace skin 1 and the cast iron stave 2 and the copper stave 3 is relatively large. Big. After selecting and determining the 4 types of slurry during the construction process, the amount of the binder should be adjusted appropriately in light of the construction seas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com