Improved laser micropore manufacturing experiment method based on penetration detection technology

A technology of detection technology and experimental method, which is applied in the field of improved laser microhole manufacturing experiments, can solve the problems of not considering the influence of drilling quality and increasing the heat-affected zone, so as to reduce the heat influence, improve reliability, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

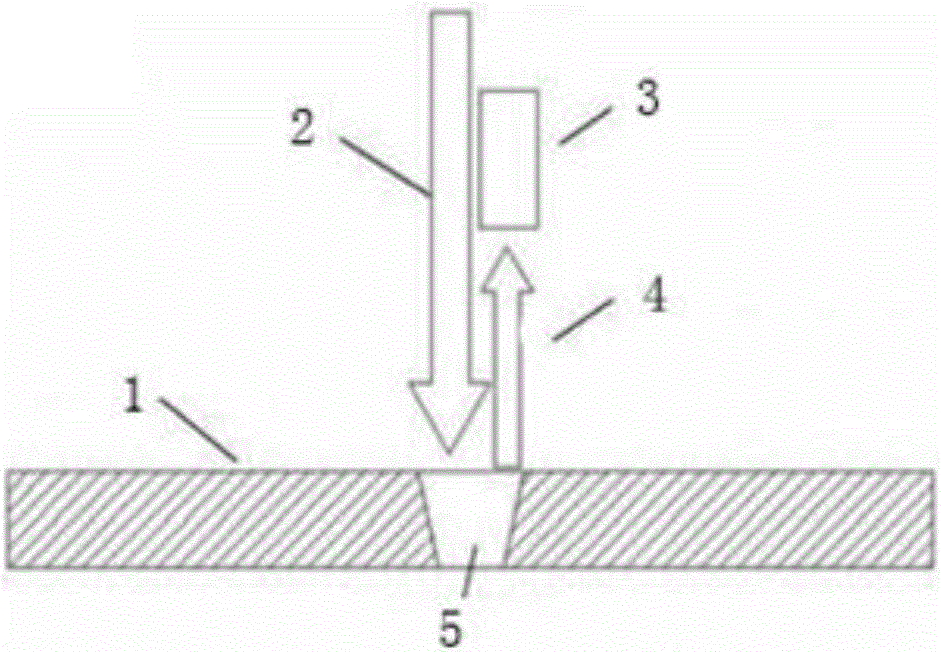

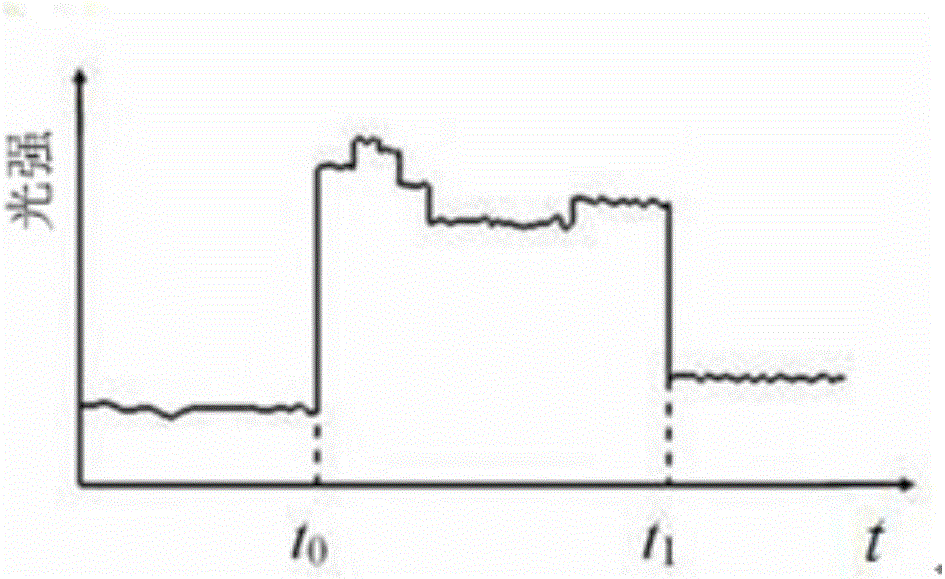

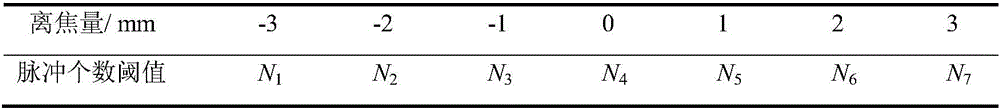

[0026] The penetration detection technology described in the present invention is as figure 1 As shown, the light intensity sensor 3 built in the optical system is mainly used to measure the intensity of the reflected light 4 on the material surface of the sample 1 during the drilling process, and the change of the intensity of the reflected light 4 is used to judge whether the micropore 5 of the material is opened. According to the thickness of the workpiece material, residues may appear at the exit of the hole after the through hole is formed, which may affect the measurement results, resulting in different reflected light intensities after the through hole is formed in different materials. The present invention can be based on specific actual conditions. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com