Automatic assembling machine for spring pen nib

A technology for assembly machines and nibs, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as loose gripping of nibs, easy swing, and impact on assembly, so as to reduce processing failures, stabilize nibs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

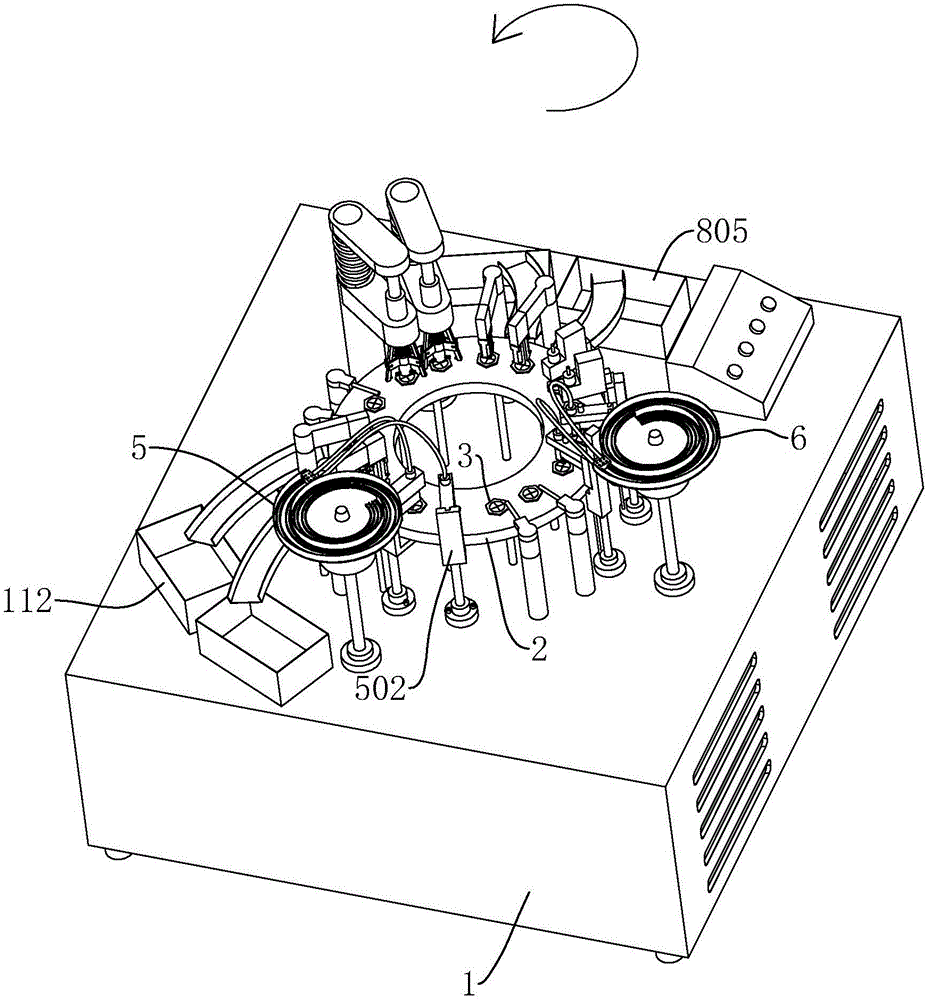

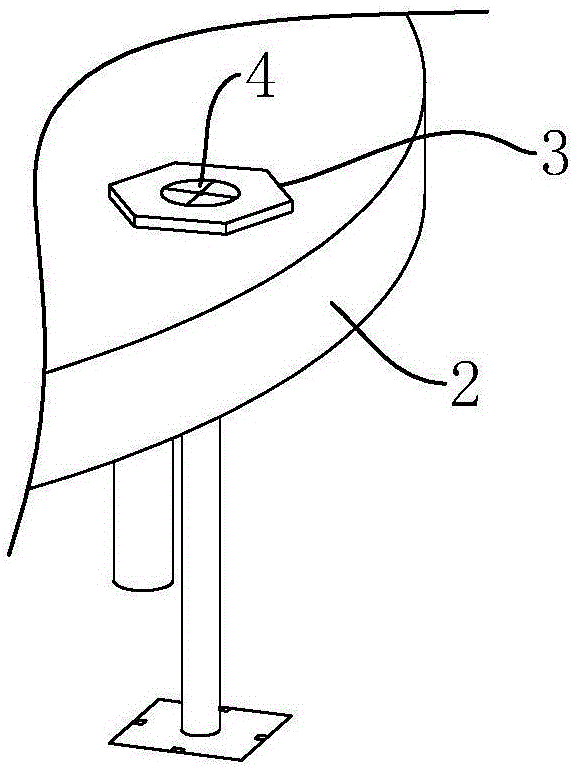

[0054] Embodiment 1: A spring nib automatic assembly machine for assembling Figure 17 Nib and spring shown. refer to figure 1 and figure 2 , The spring nib machine includes a frame 1, and the frame 1 is hinged with a transparent operation door. During actual processing, the operation door can be closed and the processing situation of the frame 1 pair can be observed. The frame 1 is equipped with a transfer tray 2, and the frame 1 is equipped with a station advance motor (not shown in the figure), and the transfer tray 2 is rotated by the control of the station advance motor. The rotation direction can refer to the figure The arrows shown point to. Twelve holders 3 are evenly distributed along the circumference of the revolving tray 2, and the holders 3 are used to hold the nib. Specific structural references for holder 3 Figure 3a to Figure 3c . The clamping seat 3 includes an upper connecting seat 301 and a lower connecting seat 302. The upper connecting seat 301 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com