Overload failure spanner handle

A wrench and handle technology, which is applied in the field of overload failure wrench handles, can solve problems such as unloading in time and easily damaged connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

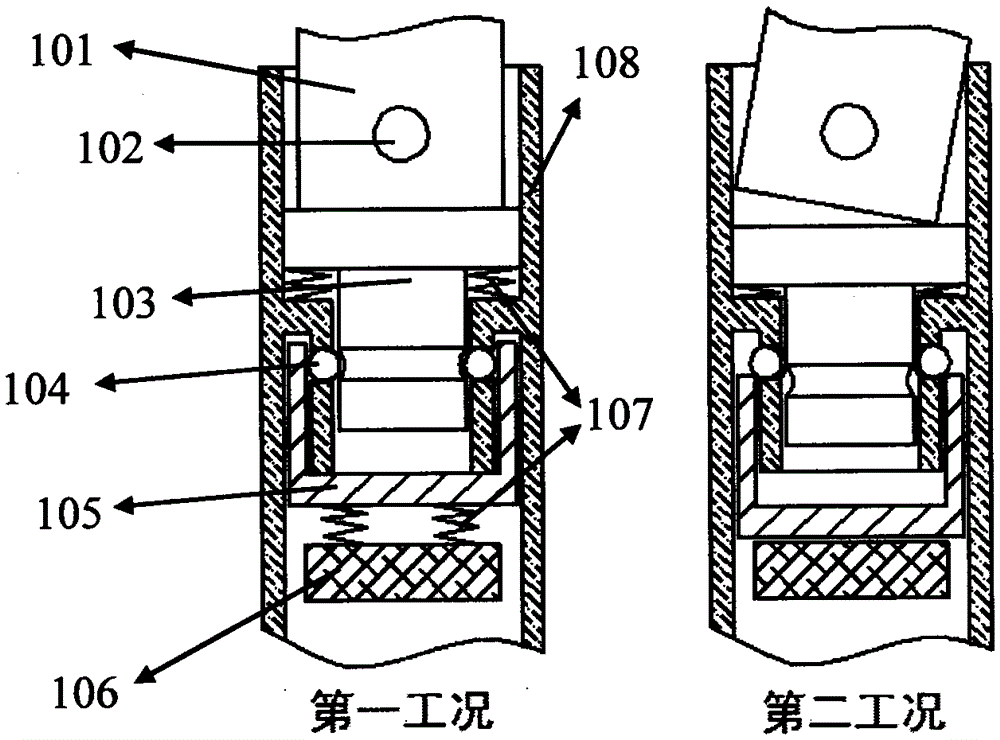

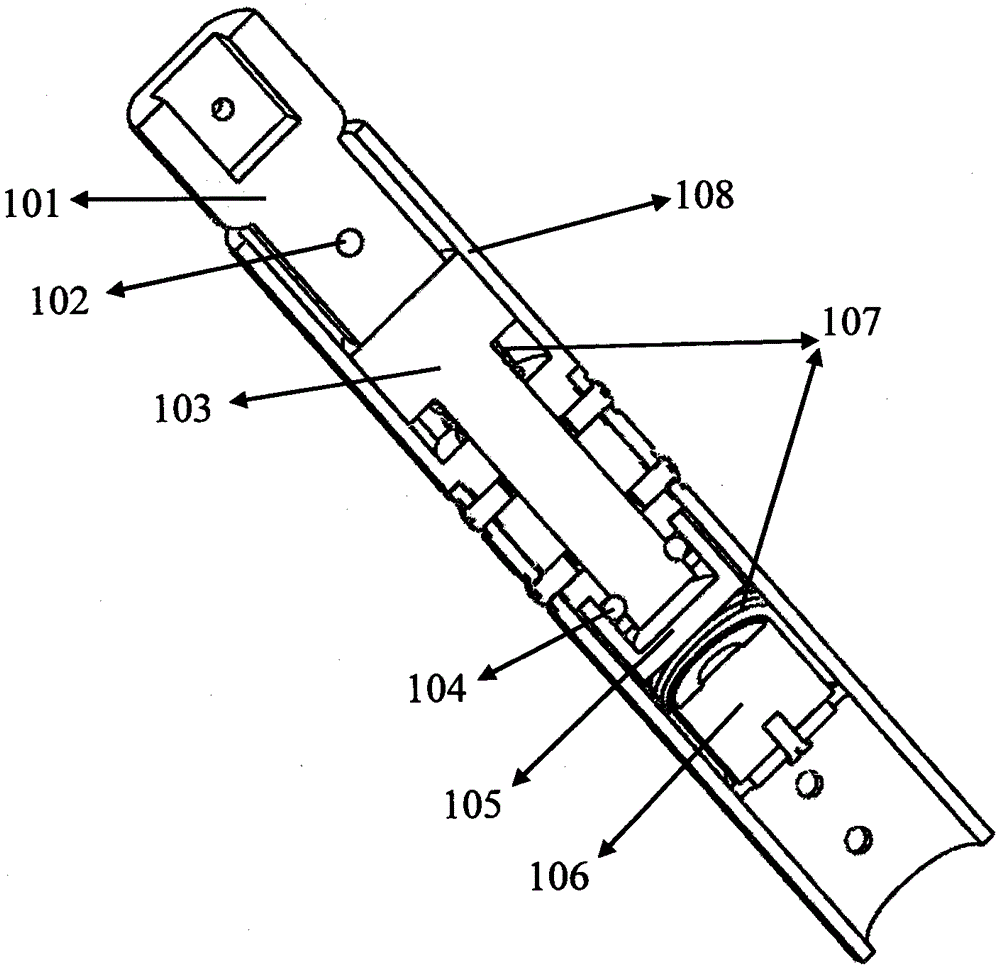

[0013] See figure 1 , The overload failure type wrench handle is composed of a connector 101, a pin shaft 102, a latch 103, a steel ball 104, a fixed sleeve 105, a return spring 107, an electromagnet 106 and a handle housing 108 and the like.

[0014] See figure 1 , figure 2 , image 3 , the connecting head 101 is installed on the handle housing 108 through the pin shaft 102, and is used for connecting the head of the wrench. There is a groove at the end of the clamp 103. When the fixed sleeve 105 is lifted by the return spring, the steel ball 104 is fixed in the groove of the clamp 103 by the fixed sleeve 105 to limit the axial movement of the clamp 103; After the 103 is limited, the upper end surface is in close contact with the lower end surface of the connector 101. At this time, the connector 101 is fixed, and the handle can apply torque. When the torque value applied by the wrench reaches the required value, the control system will power on the electromagnet 106, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com