Wood cutting machine

A cutting machine and wood technology, which is applied in the direction of wood processing equipment, sawing components, sawing equipment, etc., can solve the problems of inaccurate cutting line, deviation of wood cutting line, and manual injury, so as to facilitate manual control and cutting The effect of smooth surface and precise wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

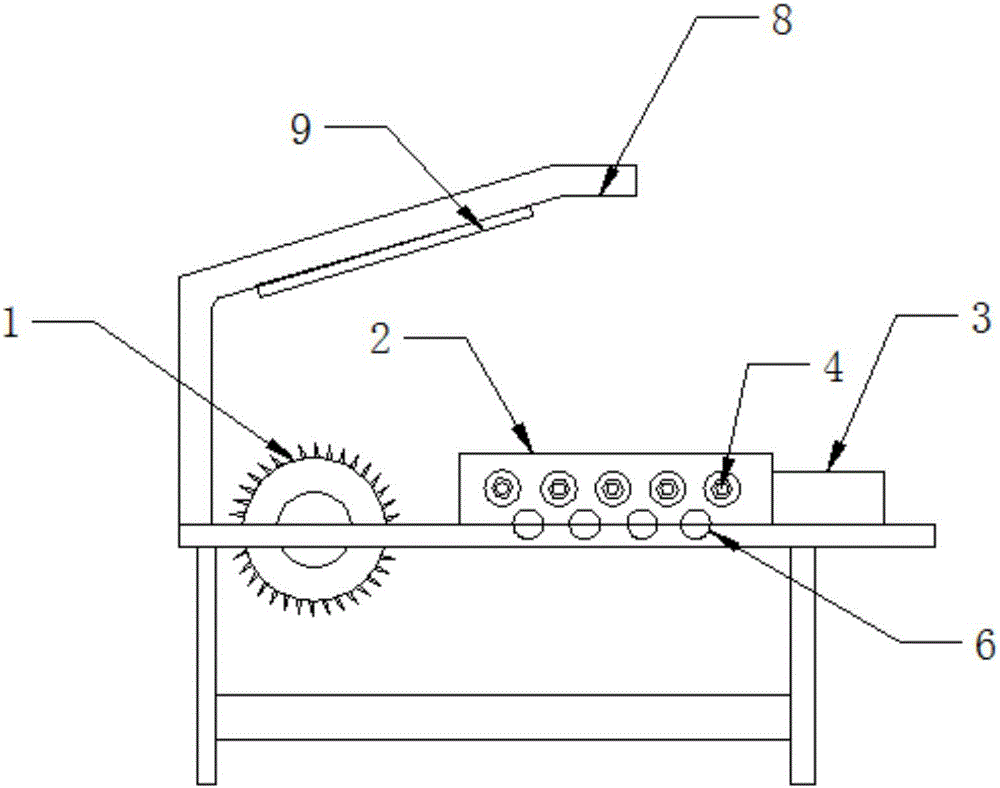

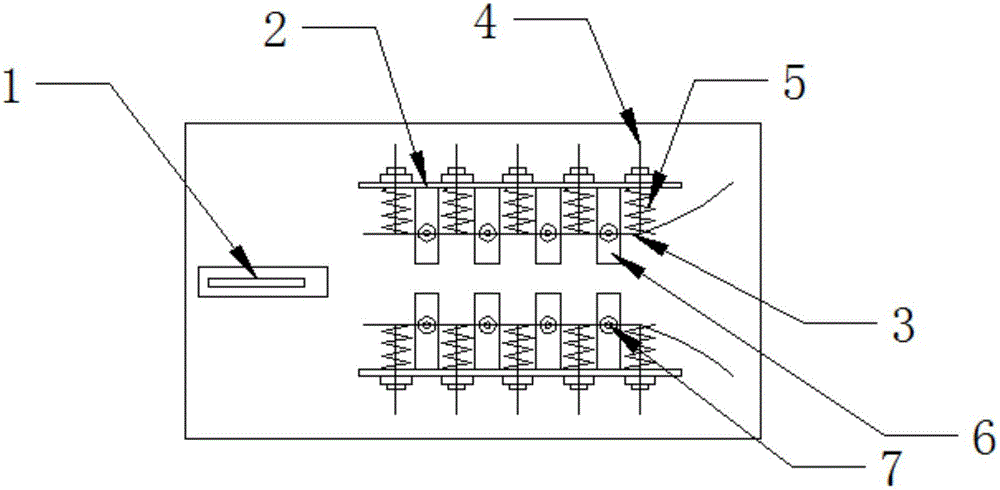

[0023] Such as figure 1 and figure 2 As shown, a wood cutting machine includes a cutting table and a saw blade 1 vertically installed on the cutting table. Two baffle plates 2 are fixedly arranged, and the two baffle plates 2 are arranged symmetrically in parallel. The saw blade 1 is installed on the front ends of the symmetrical line of the two baffle plates 2 , and the sides of the two baffle plates 2 are provided with a plurality of holes for the vertical penetration of the screw rod 4 . hole, the screw 4 can slide in the through hole, the screw 4 is sleeved with a spring 5 on the inner side of the baffle, and the screw 4 is fixedly connected to the flexible steel plate 3 at the inner side of the baffle 2; A rolling bearing 7 is horizontally arranged on the steel plate 3, and the spring 5 is in a natural state. One end of the spring 5 is fixedly connected to the flexible steel plate 3, and the other end is against the inner side of the baffle plate 2; A roller 6 is arran...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, a wood cutting machine includes a cutting table and a saw blade 1 vertically installed on the cutting table. Two baffle plates 2 are fixedly arranged, and the two baffle plates 2 are arranged symmetrically in parallel. The saw blade 1 is installed on the front ends of the symmetrical line of the two baffle plates 2 , and the sides of the two baffle plates 2 are provided with a plurality of holes for the vertical penetration of the screw rod 4 . hole, the screw 4 can slide in the through hole, the screw 4 is sleeved with a spring 5 on the inner side of the baffle, and the screw 4 is fixedly connected to the flexible steel plate 3 at the inner side of the baffle 2; A rolling bearing 7 is horizontally arranged on the steel plate 3, and the spring 5 is in a natural state. One end of the spring 5 is fixedly connected to the flexible steel plate 3, and the other end is against the inner side of the baffle plate 2; A roller 6 is arran...

Embodiment 3

[0029] Such as figure 1 and figure 2 As shown, a wood cutting machine includes a cutting table and a saw blade 1 vertically installed on the cutting table. Two baffle plates 2 are fixedly arranged, and the two baffle plates 2 are arranged symmetrically in parallel. The saw blade 1 is installed on the front ends of the symmetrical line of the two baffle plates 2 , and the sides of the two baffle plates 2 are provided with a plurality of holes for the vertical penetration of the screw rod 4 . hole, the screw 4 can slide in the through hole, the screw 4 is sleeved with a spring 5 on the inner side of the baffle, and the screw 4 is fixedly connected to the flexible steel plate 3 at the inner side of the baffle 2; A rolling bearing 7 is horizontally arranged on the steel plate 3, and the spring 5 is in a natural state. One end of the spring 5 is fixedly connected to the flexible steel plate 3, and the other end is against the inner side of the baffle plate 2; A roller 6 is arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com