Molding cavity information online detection apparatus during injection molding process

A technology of injection molding and detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

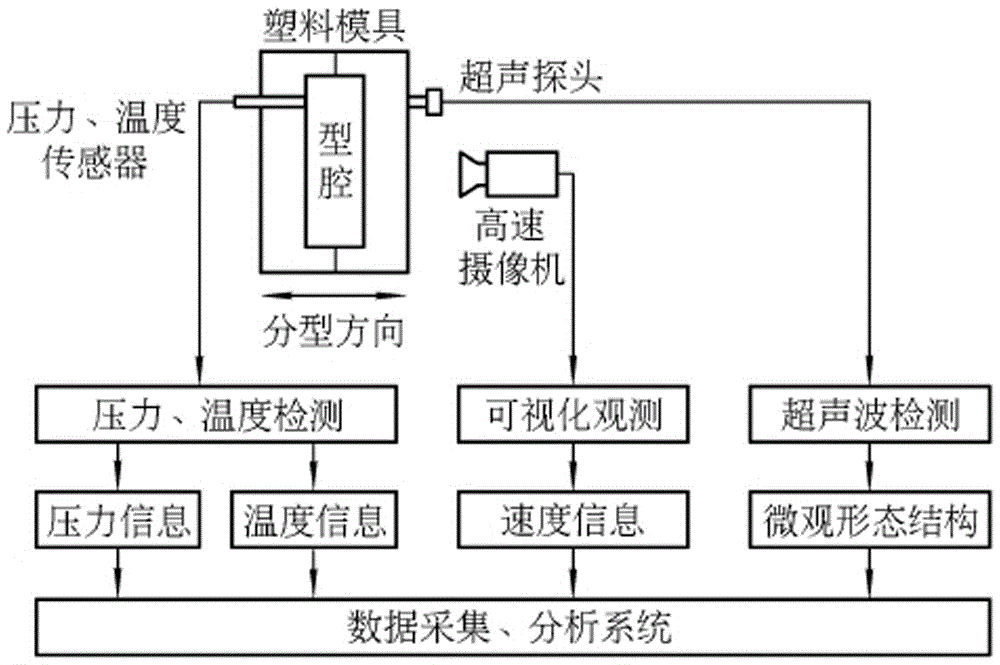

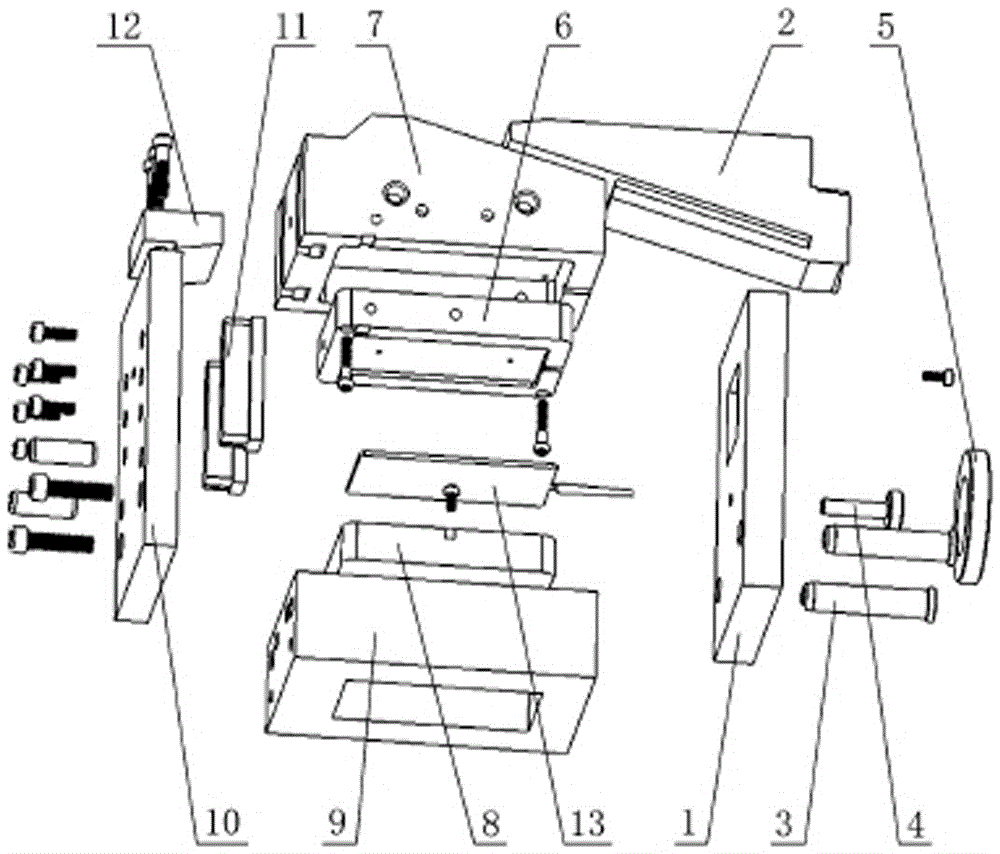

[0021] like figure 1 As shown, the online detection device for cavity information in the injection molding process is composed of plastic molds, ultrasonic probes, sensors, high-speed cameras, and data acquisition / analysis systems. The temperature and pressure sensor detection method is the simplest and most direct method to detect the cavity temperature and pressure. Online detection methods of velocity information include visual observation method and dielectric detection method. The visual inspection method uses a transparent window to replace the opaque metal mold wall, and uses a high-speed camera to record the filling behavior of the plastic melt to obtain filling speed information. The dielectric detection method utilizes the dielectric properties of the plastic melt and uses a capacitive sensor to detect the information of the filling speed of the melt on-line. The dielectric detection method needs to install two electrodes on the mold to form a capacitor. The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com