Multi-layer honeycomb plate

A honeycomb panel and honeycomb technology, which is applied in the field of materials, can solve the problems of poor mechanical properties, sound insulation effect and heat insulation performance, and achieve the effects of strengthening honeycomb panels, saving materials and improving heat insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

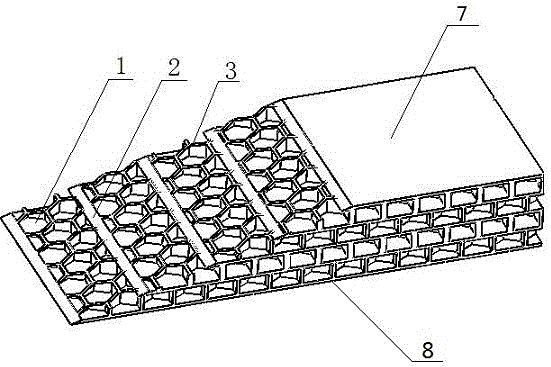

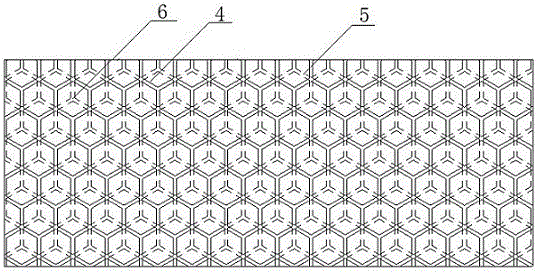

[0027] Such as figure 1 , figure 2 As shown, the multi-layer honeycomb panel is composed of a panel, a honeycomb panel 1 and a partition 2. A partition 2 is provided between the adjacent layers of the honeycomb panel. The honeycomb panel 1 is connected by a plurality of honeycomb grids 3. It is hollow, the section of the honeycomb grid 3 is a regular hexagon, and the projection of the edge intersection point 6 of the regular hexagon of the section of the honeycomb panel 1 on the section of the adjacent laminate coincides with the center of the regular hexagon of the section of the adjacent laminate.

[0028] When making multi-layer honeycomb panels, the structure of each layer of honeycomb panels 1 is the same, and the multi-layer honeycomb panels and separators 2 are stacked at intervals. The size of each layer of honeycomb panel 1 formed is also consistent.

[0029] The projection of the edge intersection point of the regular hexagon in the section of the honeycomb panel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com