Multi-functional ink supplying device

An ink supply device and multi-functional technology, applied in the field of multi-functional ink supply devices, can solve the problems of small ink storage capacity, easy pollution of the environment, and poor printing quality in ink cartridges, and achieve office space saving, broad market prospects, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

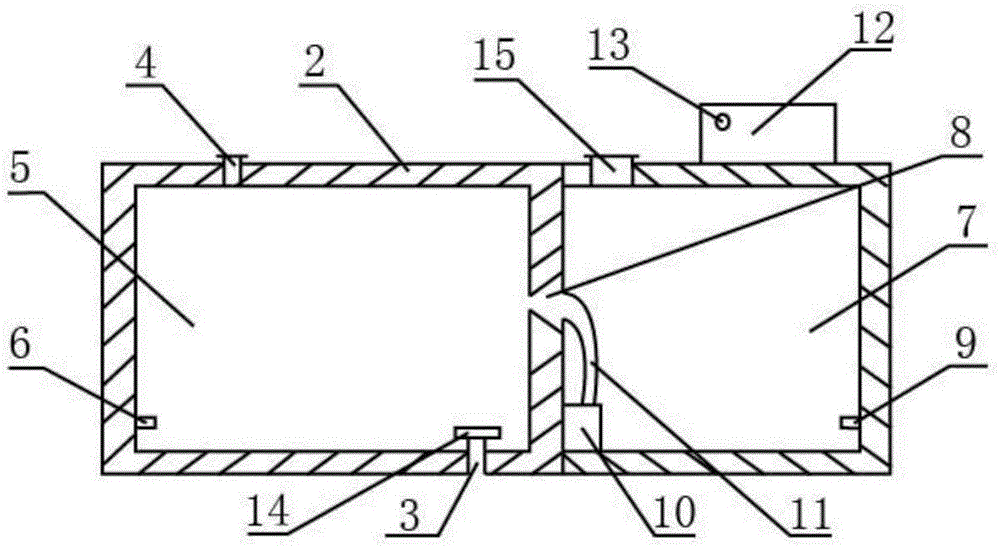

[0016] Such as figure 1 As shown, the present invention provides a multi-functional ink supply device, comprising an ink cartridge body 1, a housing 2 arranged outside the ink cartridge body 1, and an ink outlet 3 is arranged at the bottom of the ink cartridge body 1 for the outflow of ink to facilitate subsequent For printing, an air guide hole 4 is arranged on the top of the ink cartridge body 1, and the cavity in the ink cartridge body 1 forms an ink holding chamber 5, and a first liquid level sensor 6 is installed in the ink holding chamber 5, and an ink storage box 7 is arranged on one side of the ink cartridge body 1, The ink cartridge body 1 is fixedly connected with the ink storage box 7, and the junction of the two has a common connecting plate. This structure is very compact, saves the occupied space, and also saves the space in the office e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com