Non-inflatable tire

A non-pneumatic tire, non-pneumatic technology, applied in the direction of special tires, web wheels, tire parts, etc., can solve the problems of difficulty in achieving safety and comfort, inability to replace the tread alone, and loud noise. Achieve the effect of improving the scope of use, increasing the service life, and the disassembly process is convenient and simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

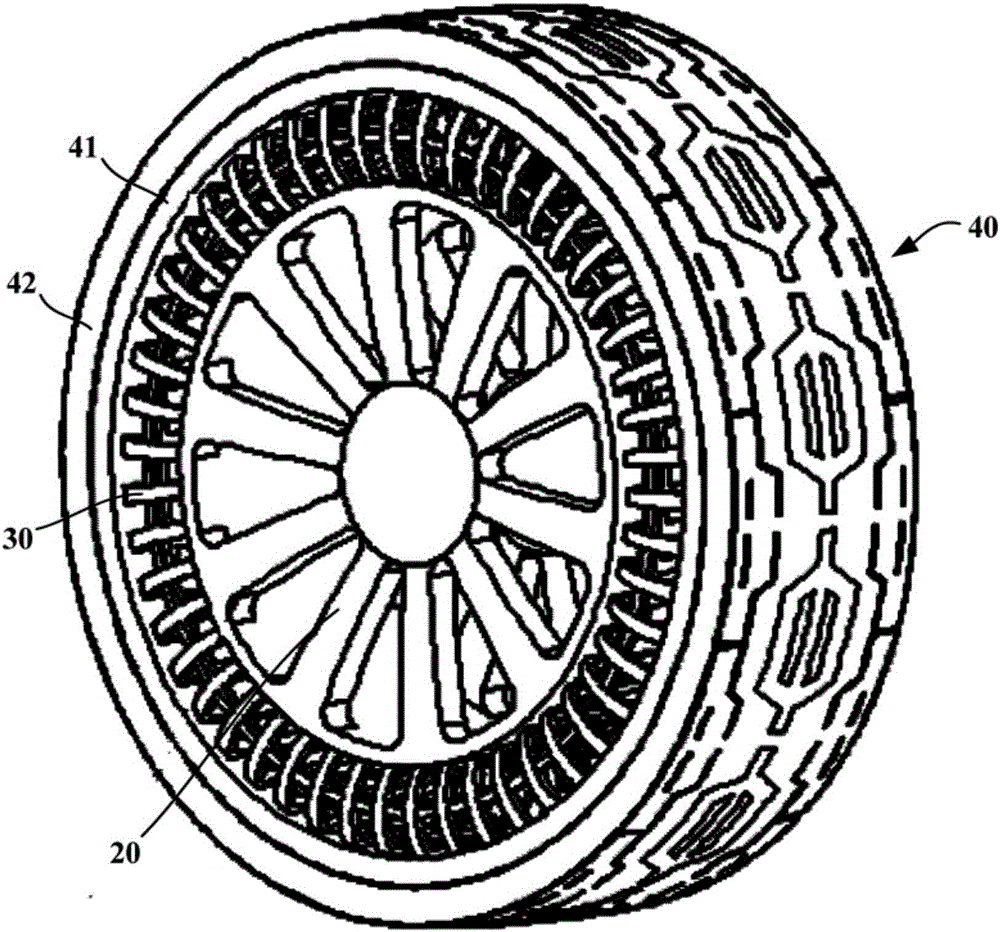

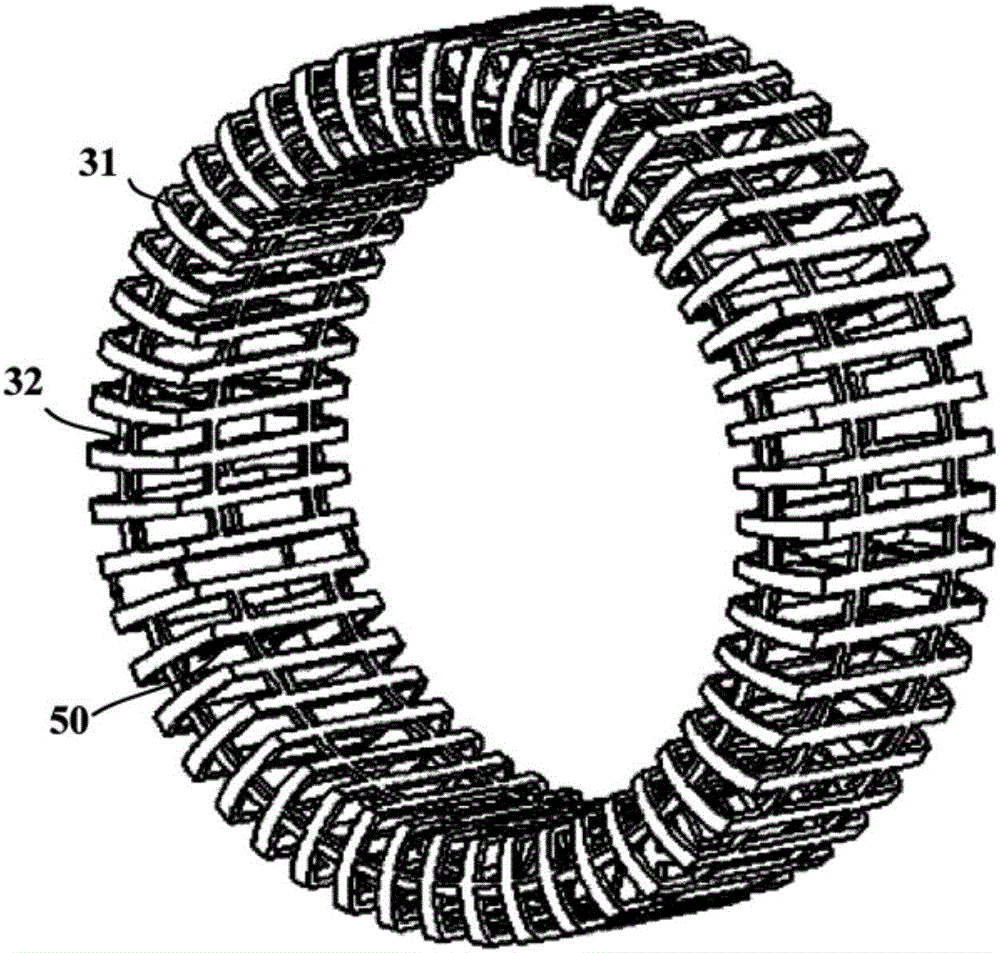

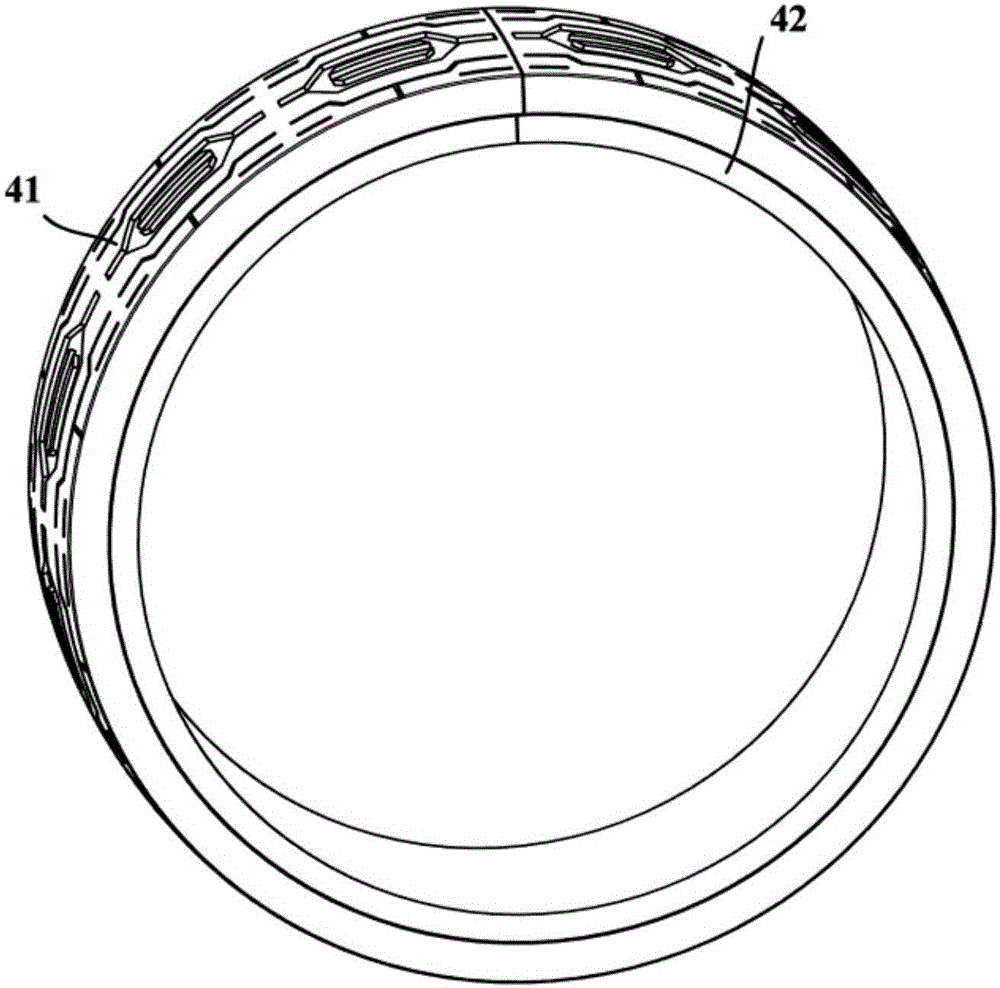

[0035] figure 1 is a schematic structural diagram of a non-pneumatic tire according to an embodiment of the present invention. like figure 1 shown, and refer to figure 2 and image 3 , the embodiment of the present invention provides a non-pneumatic tire. The non-pneumatic tire may include a rim portion 20 , a spoke portion 30 and a tread portion 40 . The rim portion 20 mainly links the axle and the members of the spoke portion 30 . The spoke portion 30 is disposed on the radially outer side of the rim portion 20 , and the spoke portion 30 is the main component and core component of the non-pneumatic tire, bearing the contact pressure of the tire and deformed by extrusion. The tread portion 40 is provided on the radially outer side of the spoke portion 30 . The non-pneumatic tire includes a rim portion 20, a spoke portion 30 and a tread portion 40, each of which is manufactured separately, realizing the modular design of the non-pneumatic tire and facilitating installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com