Switching center plate for bogies of railway trucks and method for connecting switching center plate with center plates of truck bodies

A technology for railway wagons and bogies, which is applied in the field of bogie auxiliary parts for inspection or production, and can solve the problem that different types of car bodies cannot be placed on bogies of non-corresponding types, bogie car bodies cannot be circulated in the factory, and bogie cars problems such as the inability of the body to carry out experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

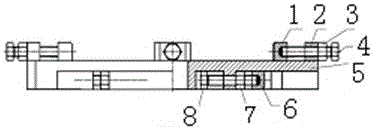

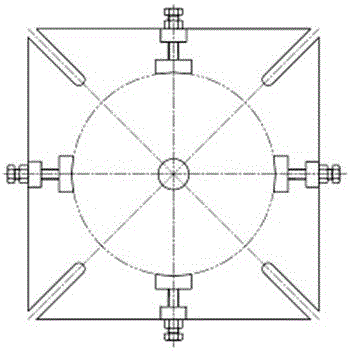

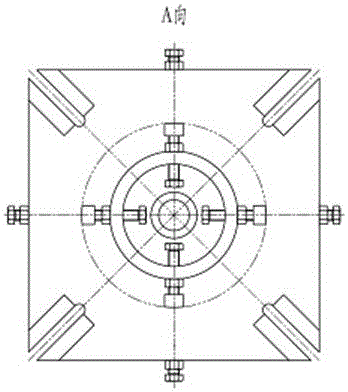

[0021] One, at first, introduce the structure of conversion center disk among the present invention, as figure 1 shown, including heart

[0022] Disc seat body 5, the upper center disc adjustment assembly that is arranged on the upper end surface of the disc base body 5 and can adjust the working inscribed circles with different radii, so that the upper discs of different types of car bodies fall in the working inscribed circles; it is arranged on the disc seat The lower end surface of the body 5 and the lower center disc adjustment assembly that can adjust the working circumscribed circles with different radii, so as to be able to fall in the lower center discs of different models of car bodies.

[0023] Wherein, the upper center disc adjustment assembly includes an adjustment baffle plate 2 fixed on the edge of the upper end surface of the center disc seat body 5, and an upper adjustment bolt 4 passing through the adjustment baffle plate 2; One end is provided with an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com