Design method of integrated tube bundle units in ultra-large container ship torsion box

A container ship and design method technology, applied in ship design, ship parts, ship construction, etc., can solve the problems that the outfitting operation and hull operation cannot be carried out in parallel, affect the ship construction cycle, and the number of brackets is too large, so as to save ships The effect of improving the construction period, improving labor intensity, and reducing the number of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

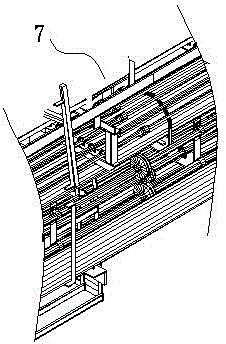

[0037]The design method of the comprehensive tube bundle unit in the torsion box of a super-large container ship of the present invention will be further described in detail below in conjunction with the accompanying drawings, in order to understand the application process of the method of the present invention more clearly, but it cannot be used for this purpose. Limit the protection scope of the present invention.

[0038] like Figure 1~Figure 15 As shown, the design method of the comprehensive tube bundle unit in the torsion box of the ultra-large container ship of the present embodiment, the design method includes the following steps:

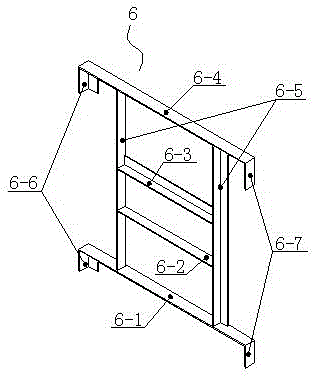

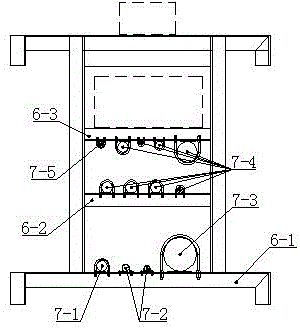

[0039] S1, the combined bracket layout design of the tube bundle unit, such as figure 1 As shown, the combined bracket 6 is supported by the bottom horizontal frame support 6-1, the first auxiliary horizontal support 6-2, the second auxiliary horizontal support 6-3, the top floor horizontal frame support 6-4, and two vertical angle steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com