Floating rear shelving single jib crane

A crane and single-arm technology, applied to cranes and other directions, can solve the problems of reducing engineering costs, unfavorable stability, and high center of gravity, and achieve the effects of reducing cost, improving market competitiveness, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

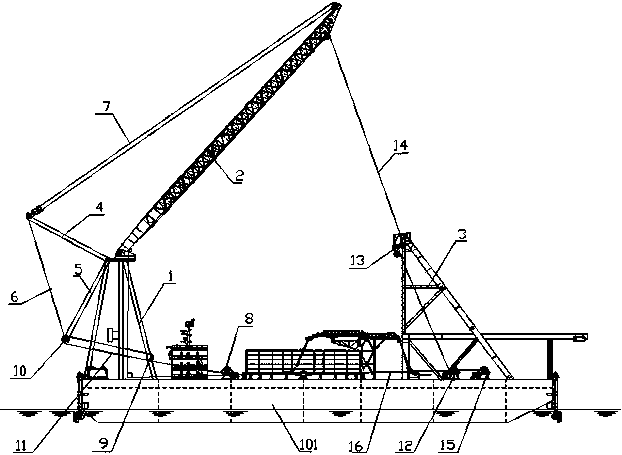

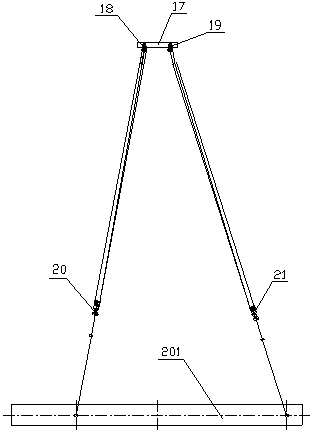

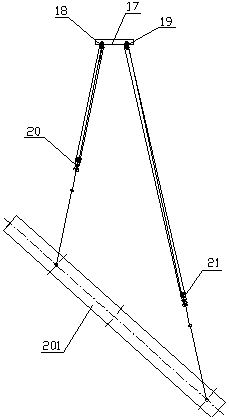

[0032] see Figure 1~7 , the present invention relates to a floating rear laying single jib crane, the floating rear laying single jib crane includes a support 1 and an A frame 3 installed on the hull 101, and the bottom of a jib 2 is hinged on top of support 1;

[0033] One end of the turning auxiliary lever one 4 and one end of the turning auxiliary lever two 5 are jointly hinged on the support 1 (preferably, the turning auxiliary lever one 4 and the turning auxiliary lever two 5 form an L-shaped structure), and the turning auxiliary lever one Between the other end of 4 and the other end of flipping auxiliary rod two 5, there is a tension wire rope 6 (preferably, flipping auxiliary rod one 4, flipping auxiliary rod two 5 and tensioning wire rope 6 form a triangular structure), and the flipping There is a main hoisting wire rope 7 between the top of the auxiliary rod one 4 and the jib 2, the pulley block 10 is installed on the said turning auxiliary rod two 5, the fixed pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com