Device and method for inhibiting platinum group element particle defects in cover glass

A technology for particle defects and cover glass, which is applied in the field of devices for suppressing particle defects of platinum group elements in cover glass, can solve the problems that restrict the production yield, improve the quality of cover glass, melting defects, etc. particle defects, easy to use, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

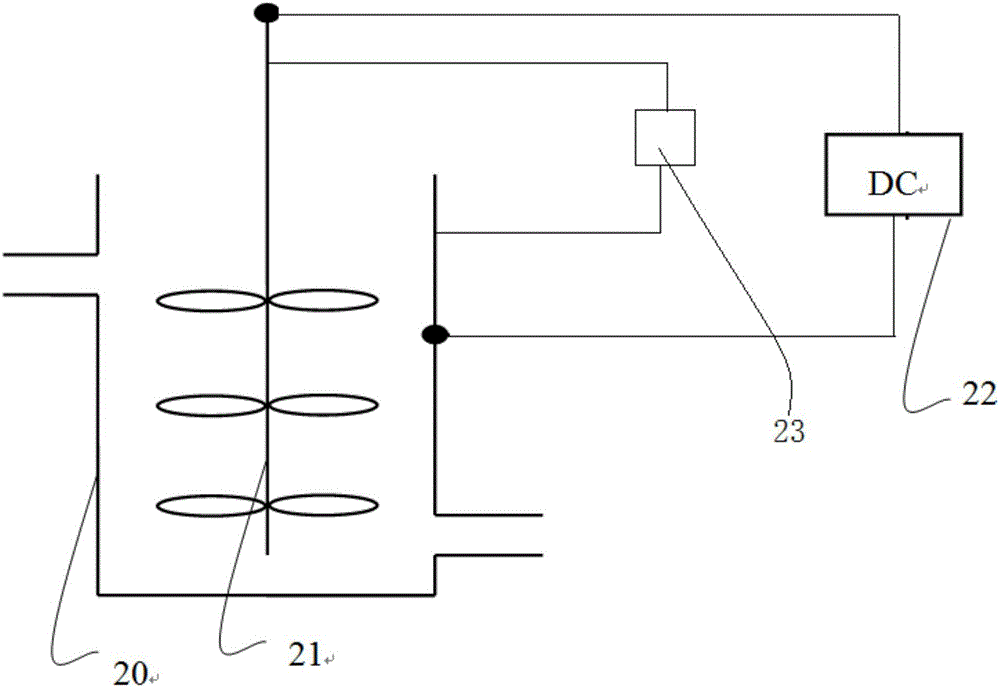

[0026] Such as figure 2 As shown, a device for suppressing the defects of platinum group element particles in the cover glass includes a potential difference measuring device 23 connecting two non-contacting parts in the glass channel and a DC stabilized voltage power supply connecting the two non-contacting parts in the glass channel 22. Both the potential difference measuring device 23 and the DC regulated power supply 22 are connected to the control feedback device, wherein the potential difference measuring device is specifically a potentiometer, and the potentiometer is TX1100A.

[0027] A method of suppressing PGE particle defects in cover glass by grounding non-directly connected components of a glass channel system. Specifically include: connecting a potential difference measuring device 23 and a DC stabilized power supply 22 between two non-contacting parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com