A kind of tile glue and its preparation method and application

A tile adhesive and rubber powder technology, applied in the field of building materials, can solve the problems of insufficient adhesive bonding performance, long construction time, narrow application range, etc., and achieve the effects of simplified operation, good waterproof effect, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

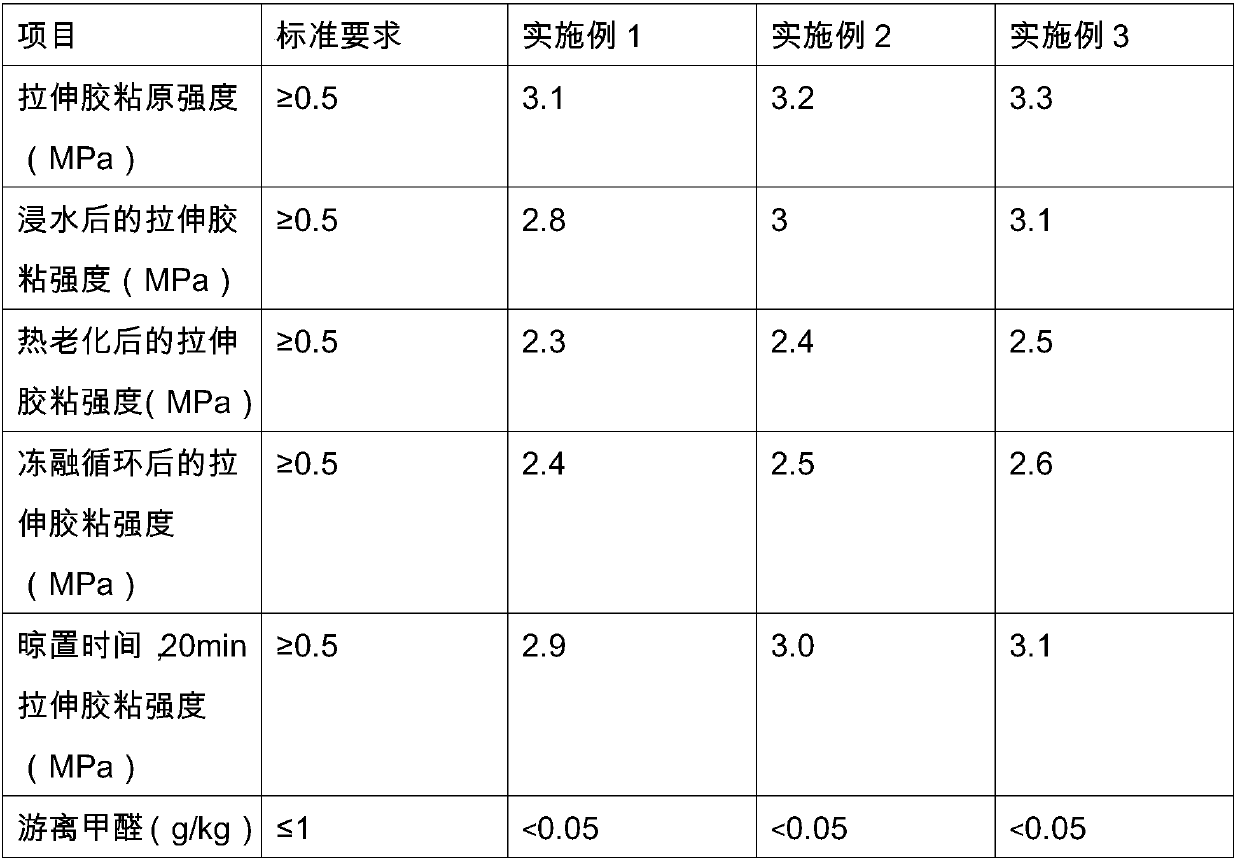

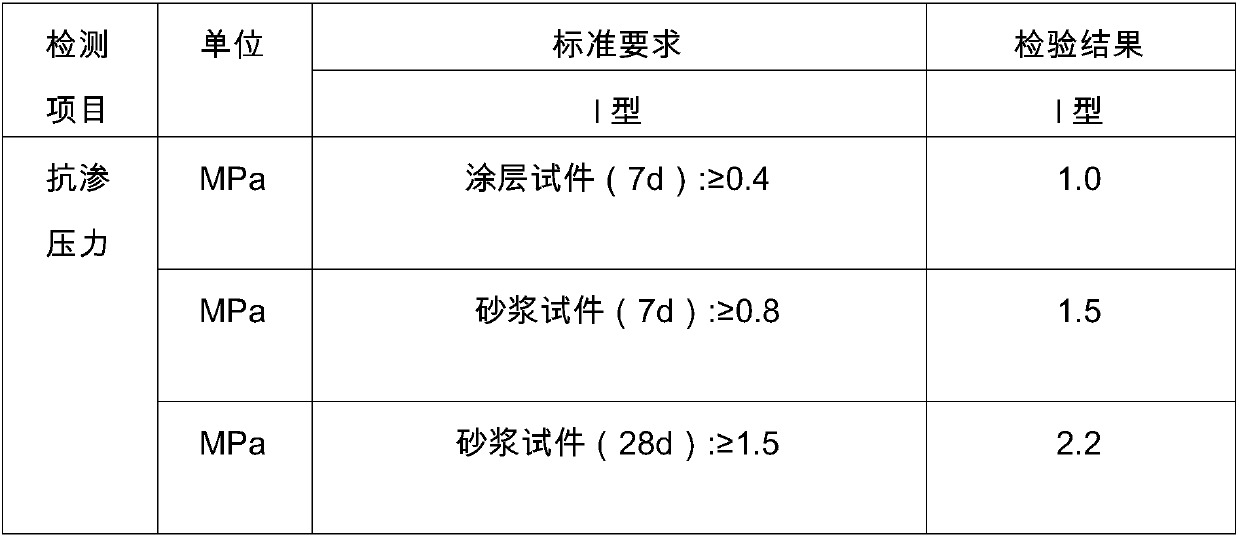

Examples

Embodiment 1

[0017] Preparation:

[0018] In parts by weight, take 600 parts of 425# black cement, 25 parts of redispersible latex powder, 6 parts of hydroxypropyl methylcellulose, 250 parts of quartz sand, and 150 parts of gypsum powder. Put 200 parts of 425# black cement into the container first, then put 250 parts of quartz sand; then put 6 parts of hydroxypropyl methylcellulose and 25 parts of redispersible latex powder; finally put the remaining cement and 150 parts of gypsum powder , and stir evenly to obtain rubber powder.

[0019] Application method: clean the old tiles first, so that there is no oil stain, batik and looseness on the old tiles. The above-mentioned rubber powder and water are configured in a ratio of 4:1 by weight. First pour the water into the container, then add the rubber powder, and stir with an electric mixer until there are no particles in the paste.

[0020] Scrape the above-mentioned paste tile adhesive twice on the surface of the old tiles. After the til...

Embodiment 2

[0022] Preparation:

[0023] In parts by weight, take 540 parts of 425# black cement, 30 parts of redispersible latex powder, 6.5 parts of hydroxypropyl methylcellulose, 280 parts of quartz sand, and 180 parts of gypsum powder.

[0024] Put 180 parts of 425# black cement into the container first, then put 280 parts of quartz sand; then put 5.5 parts of hydroxypropyl methylcellulose and 30 parts of redispersible latex powder; finally put the remaining cement and 180 parts of gypsum powder , and stir evenly to obtain rubber powder.

[0025] Application method: clean the old tiles first, so that there is no oil stain, batik and looseness on the old tiles. The above-mentioned rubber powder and water are configured in a ratio of 4:1 by weight. First pour the water into the container, then add the rubber powder, and stir with an electric mixer until there are no particles in the paste. Scrape the above-mentioned paste tile adhesive twice on the surface of the old tiles. After the...

Embodiment 3

[0027] Preparation:

[0028] In parts by weight, take 690 parts of 425# black cement, 28 parts of redispersible latex powder, 6 parts of hydroxypropyl methylcellulose, 300 parts of quartz sand, and 200 parts of gypsum powder.

[0029] Put 230 parts of 425# black cement into the container first, then put 300 parts of quartz sand; then put 6 parts of hydroxypropyl methylcellulose and 28 parts of redispersible latex powder; finally put the remaining cement and 200 parts of gypsum powder , and stir evenly to obtain rubber powder.

[0030] Application method: clean the old tiles first, so that there is no oil stain, batik and looseness on the old tiles. The above-mentioned rubber powder and water are configured in a ratio of 4:1 by weight. First pour the water into the container, then add the rubber powder, and stir with an electric mixer until there are no particles in the paste. Scrape the above-mentioned paste tile adhesive twice on the surface of the old tiles. After the til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com