A three-hole dipping tube for a single-nozzle refining furnace

A single-nozzle refining furnace and dipping tube technology, applied in the field of vacuum degassing devices, can solve the problems of long horizontal length of retaining wall, short life of single-nozzle dipping tube, deformation and collapse, etc., to improve support strength, reduce mutual interference, reduce The effect of the loop dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

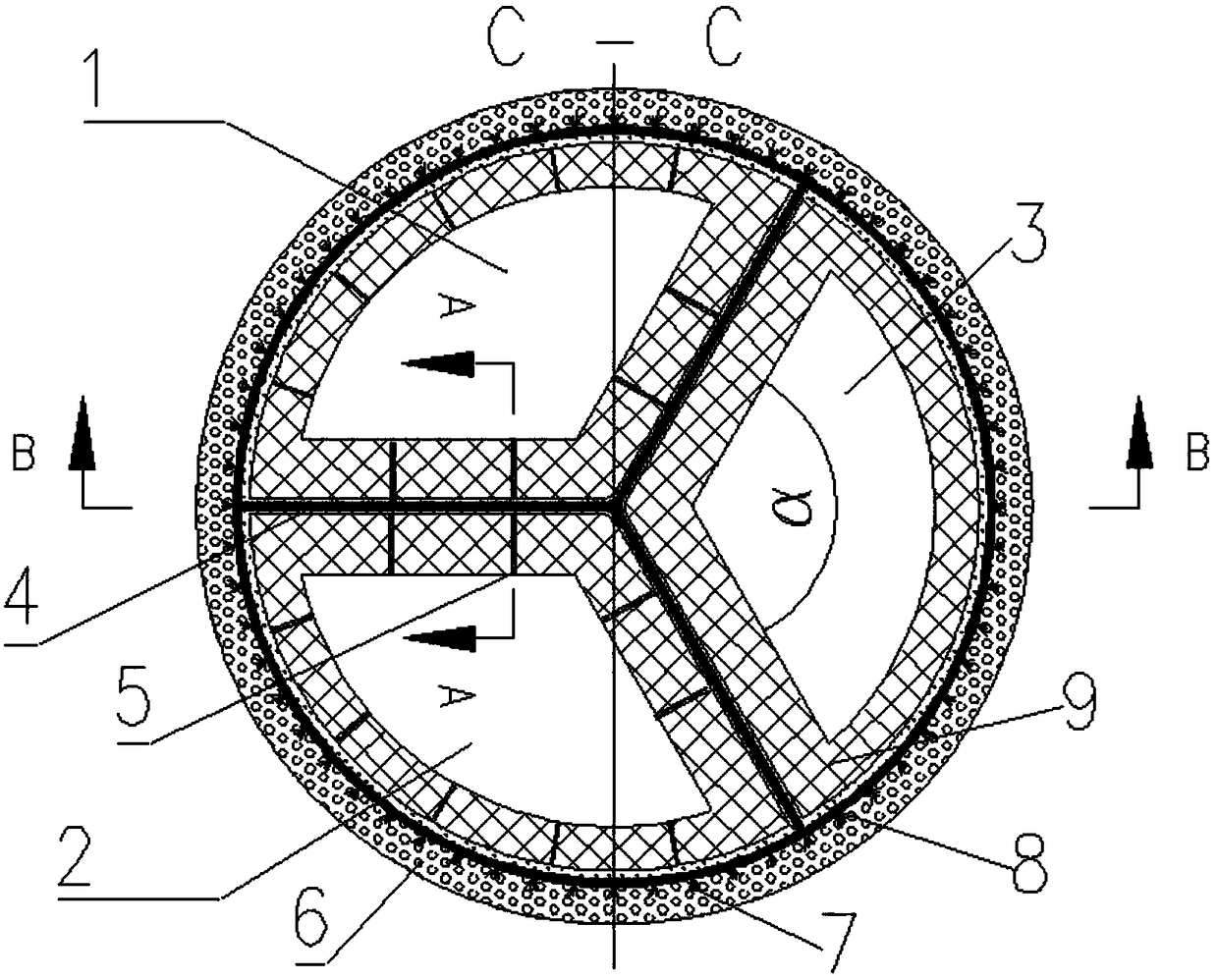

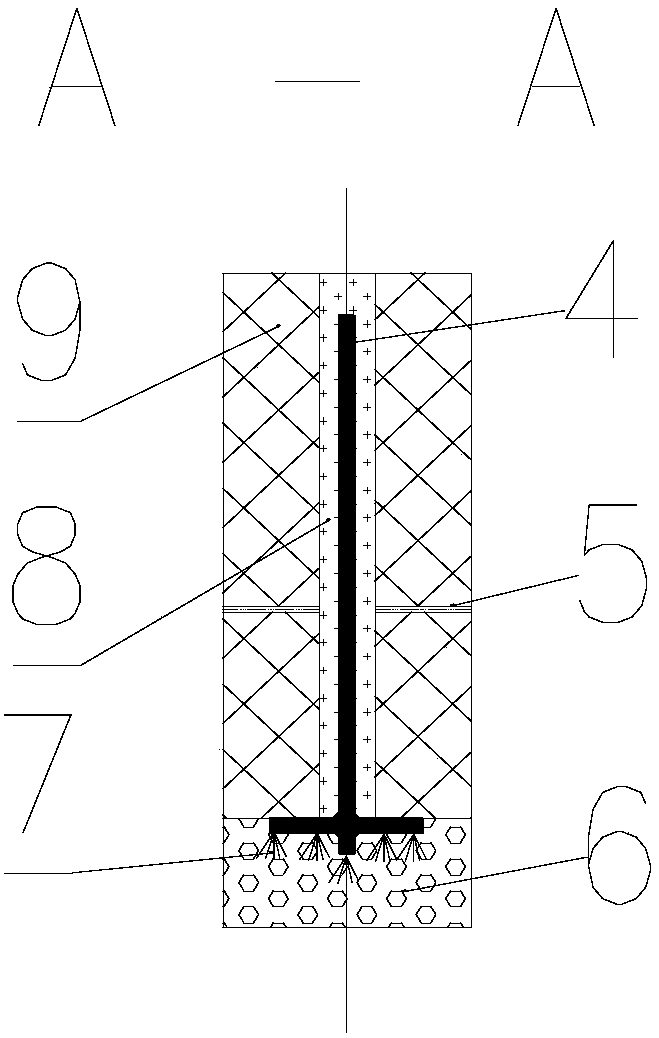

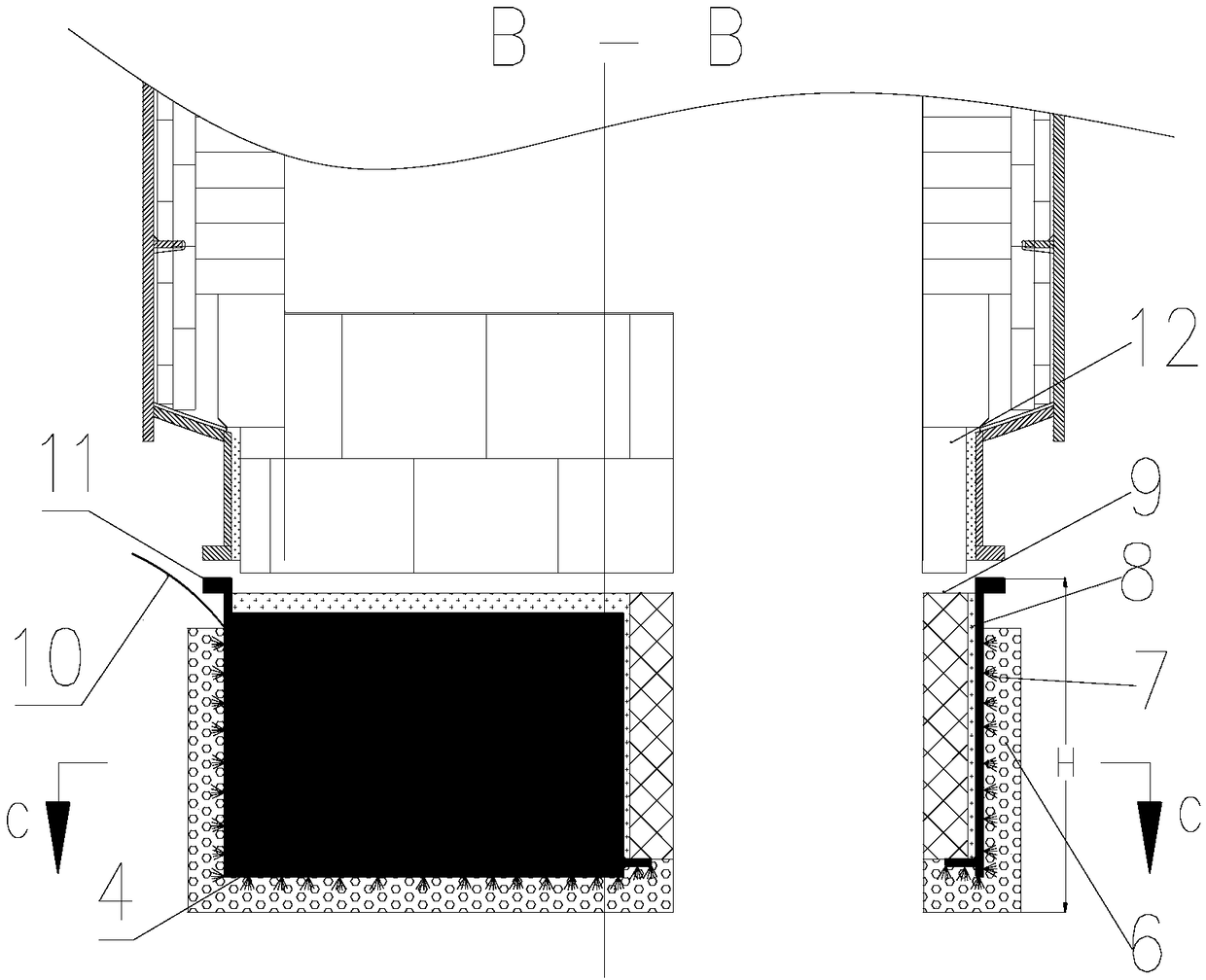

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0045] The invention is applied to the transformation of the immersion tube and the vacuum chamber of the 150T RH furnace. The vacuum chamber and the immersion tube of the RH are modified simultaneously, and both are changed into a cylindrical single nozzle structure. The specific structure is as figure 1 , figure 2 and image 3shown. The dipping pipe is a cylindrical single-mouth three-hole structure. The three inner retaining walls and the outer arc-shaped outer wall jointly form the ascending hole I1, the ascending hole II2, and the descending hole 3. There is a hole around the inner walls of the ascending hole I1 and the ascending hole II2. Layer lifting gas outlet 5, the lifting gas outlet 5 is in communication with the lifting gas pipeline 10. Anchor nails 7 are arranged on the outer peripheral wall and bottom of the inner tank 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com