An anti-corrosion grounding device

A grounding device and grounding electrode technology, which is applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of inconvenient construction, large cost of money, and easy damage to the coating film, so as to improve construction efficiency and speed and reduce construction cost. cost, the effect of increasing the equivalent diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easier for those skilled in the art to understand, the present invention will be described in more detail below in conjunction with specific embodiments and accompanying drawings.

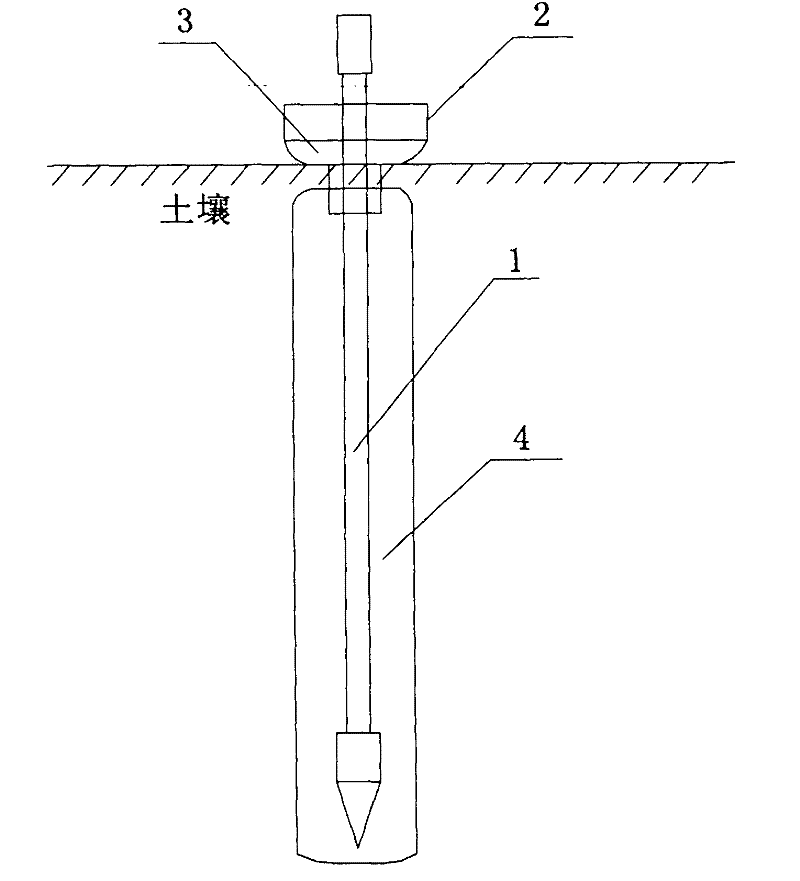

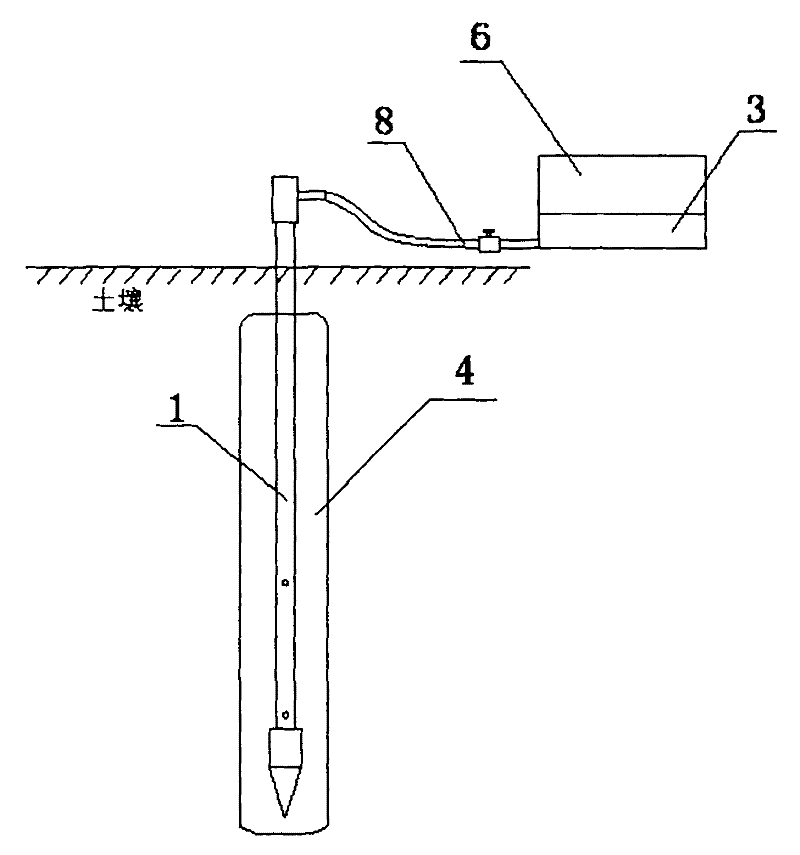

[0021] refer to figure 1 , figure 2 , an anti-corrosion grounding device, the grounding device includes a drive-in grounding electrode 1 and a potting device, as well as a protective layer 4 formed by potting slurry 3 .

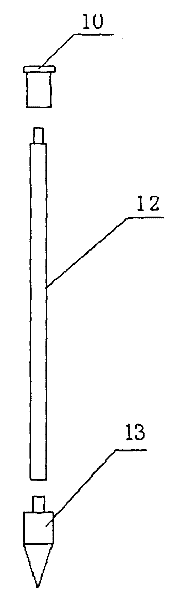

[0022] The drive-in grounding electrode 1 is composed of a striking head 10, a grounding trunk 12, and a ground-boring cone 13. The ground-boring cone 13 includes a tapered head 132 at one end and a tail 131 detachably connected to the grounding trunk. The head 132 is Cone, the tail 131 is a cylinder, and the radius of the bottom surface of the cylinder is greater than the outer diameter of the grounding trunk 12 . The potting device used in conjunction with it is composed of a potting funnel 2, a discharge hole is provided at the bottom of the funnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com