Bidirectional high-shrink sanded home textile fabric

A high-shrinkage, high-shrinkage yarn technology, used in textiles, household appliances, textiles and papermaking, etc., can solve the problems that have not been properly solved, high-shrinkage yarns are not suitable, and the weight of fabrics is high. It is convenient for market promotion, rich in types, Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A two-way high-shrinkage brushed home textile fabric, specifications: warp density 381 threads / 10cm, weft density 256 threads / 10cm, width 106 inches. The warp yarn is made of compact spun cotton 21S and polyester high shrinkage yarn 100D / 48F in a ratio of 1:1, and the weft yarn is also made of compact spun cotton 21S and polyester high shrinkage yarn 100D / 48F in a ratio of 1:1.

[0015] Its design and development steps are as follows:

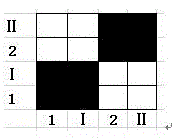

[0016] (1) Organization design: In order to exert the effect of high shrinkage and ensure uniform polishing, the organization adopts a square shape to form a concave-convex feeling.

[0017] (2) Warping: The warp cotton is warped in batches, and the polyester high shrinkage is warped in sections.

[0018] (3) Sizing: Cotton sizing adopts a starch-based sizing formula; polyester high-shrinkage yarn uses a modified starch-based sizing formula, supplemented by PVA. The sizing adopts the fixed volume method and follows the principle of "hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com