Pat extrusion type full-automatic washing machine

A fully automatic washing machine, extrusion technology, applied in the field of washing machines, can solve the problems of limiting the appearance of the washing machine and the diversity of the appearance of the inner tub, the difficulty of implementing technology, consuming material costs and labor costs, etc., to achieve a simple and reliable design structure, avoid Clothing secondary pollution, easy to clean and maintain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described here are only used to explain the present invention, not to limit the present invention.

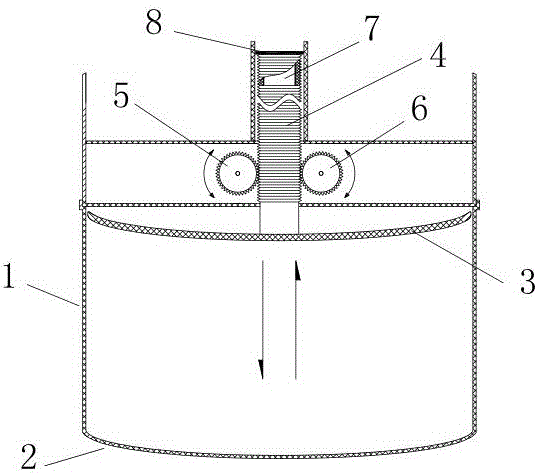

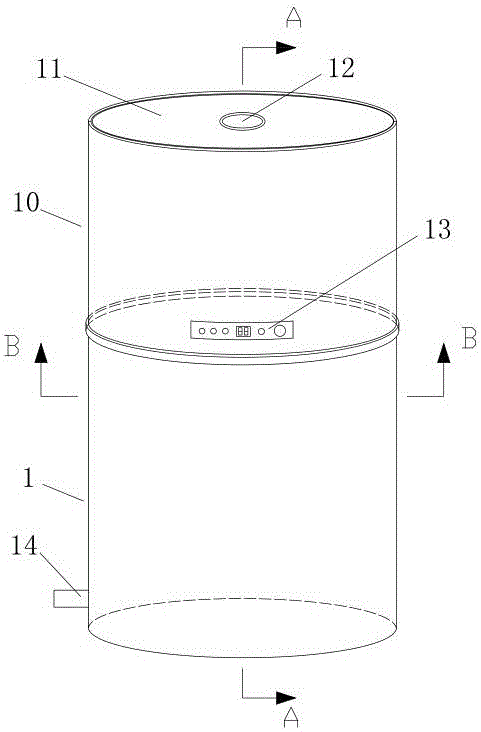

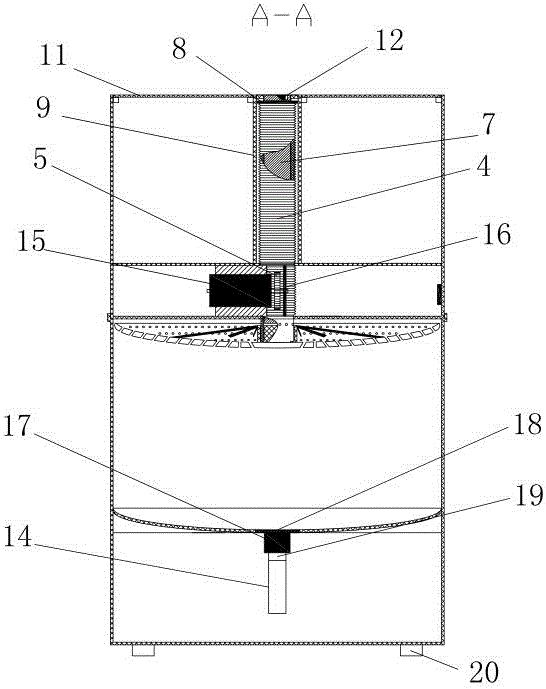

[0036] refer to figure 1As shown, this embodiment adopts a beating and squeezing washing method, and a washing board (3) that can reciprocate up and down is arranged in the washing bucket (1), and the washing board (3) is connected to the toothed post (4). Driven by the reversible driving gear (5), the toothed column (4) is combined with the positioning of the positioning guide seat (8), the positioning guide column (7), the driven gear (6) and the gear bracket (16). Guide function, reciprocating mechanical movement up and down in the washing bucket (1) and continuous mechanical movement in one direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com