Needle detecting machine for cloth

A needle detector and fabric technology, which is used in the inspection of textile materials, marking of textile materials, textiles and paper making, etc. Efficiency, increased utilization, full effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

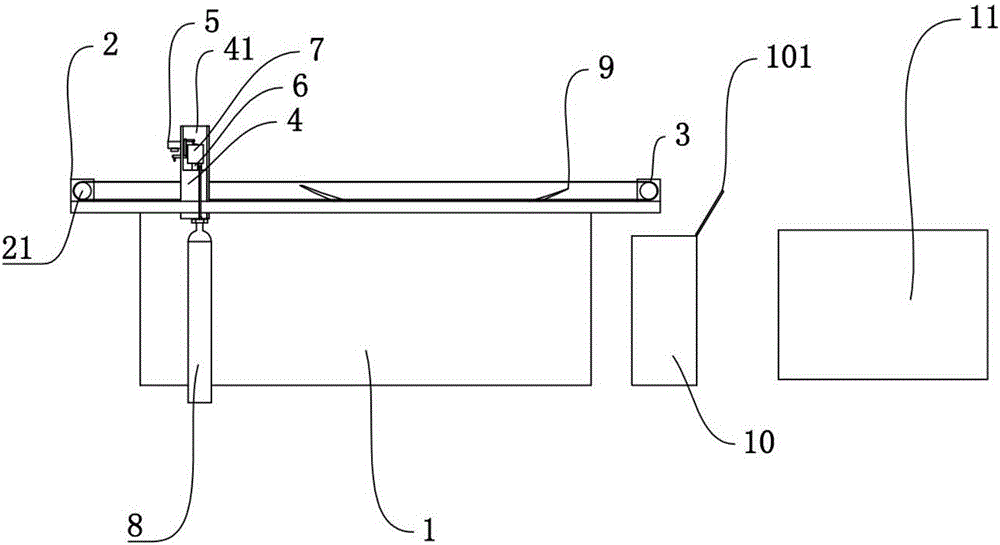

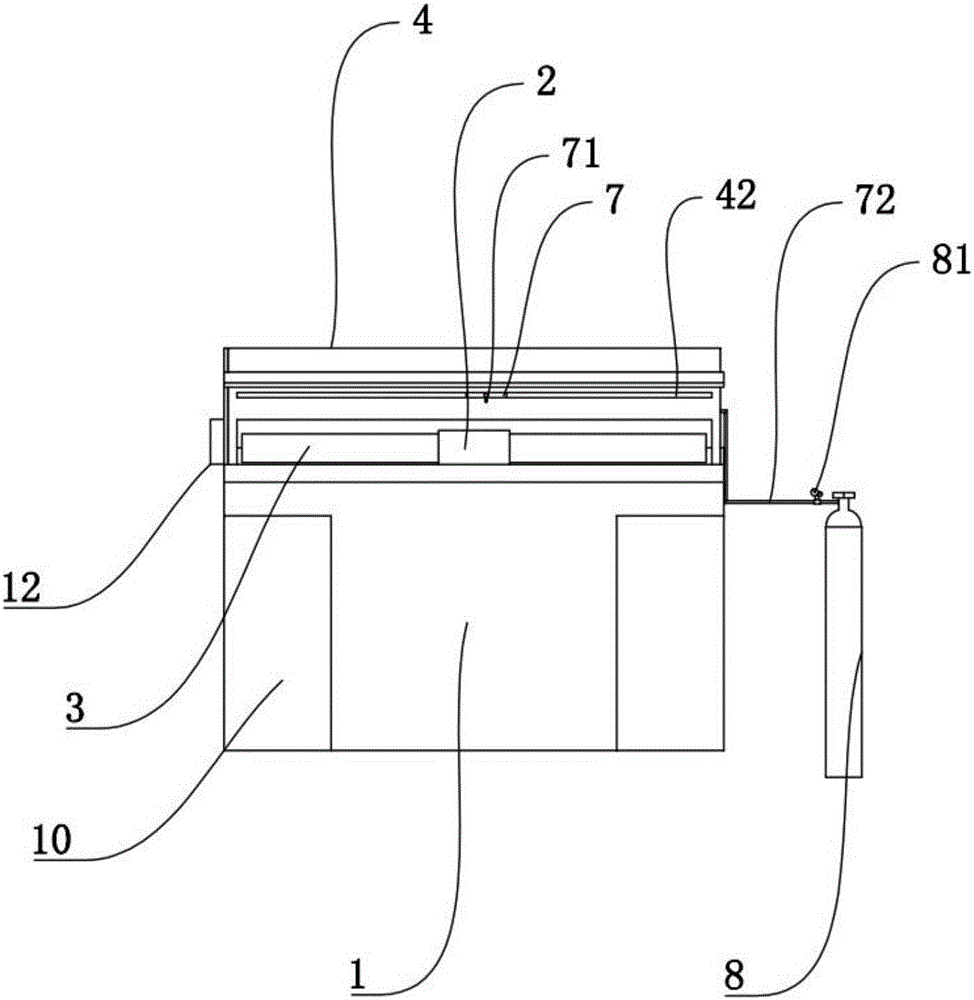

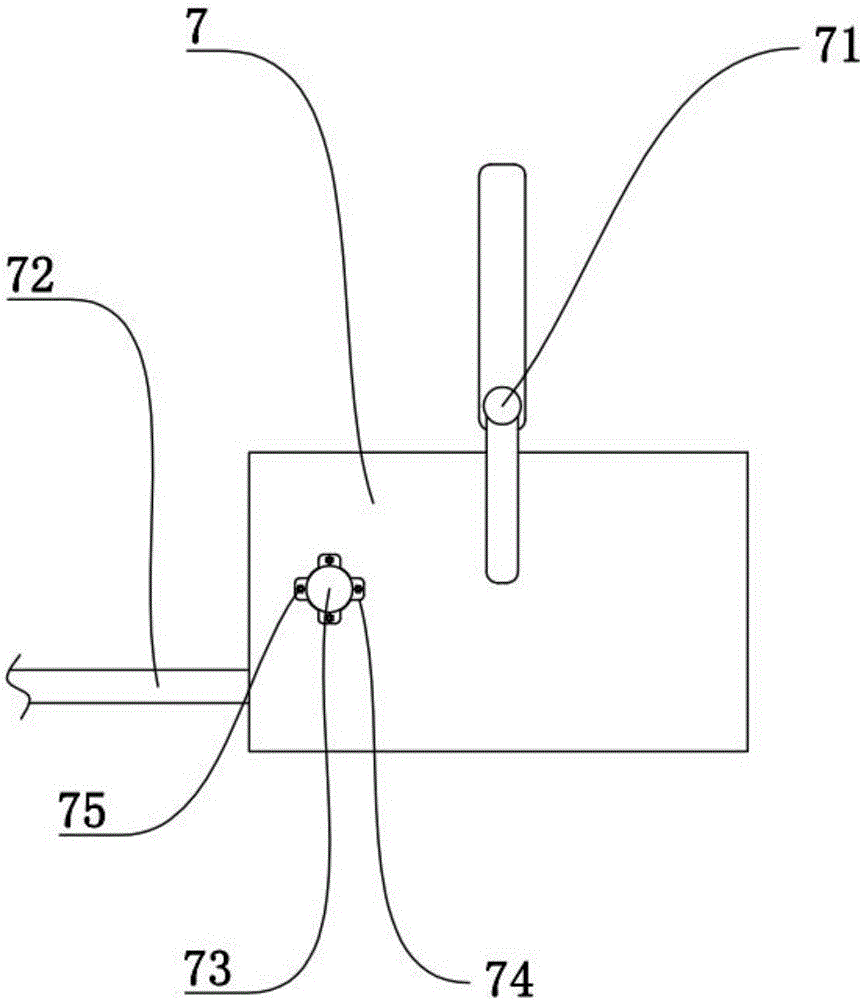

[0037]The invention discloses a fabric needle detector, comprising a frame 1, a door frame 4 arranged on the frame 1, a conveyor belt 3 positioned on the frame 1 through a rotating shaft 21, and a motor 2 for driving the conveyor belt 3 The door frame 4 is erected above the conveyor belt 3, and the side of the door frame 4 facing the feeding is provided with a metal detector 5. The detection port of the metal detector 5 faces the conveyor belt 3 and is arranged in strips along the width direction of the conveyor belt 3. A concave cavity 41 with an upward opening is provided on the top, and a rectangular slot 42 is provided at the end of the door frame 4 close to the port of the metal detector 5. A powder spraying device is fixed in the cavity 41, and the cover powder spraying device is fixed in the groove. The fixed seat 6 at the bottom is fixed, and the powder spraying device includes a powder spraying box 7. The upper end surface of the powder spraying box 7 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com