Intelligent anchor cable system and its fixing method suitable for rock slope support and whole-process monitoring

A technology for rock slopes and anchor cables, applied in foundation structure engineering, foundation structure tests, construction, etc., can solve problems such as difficult to respond to the working state of prestressed anchor cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the drawings, but it is not intended to limit the implementation scope of the present invention.

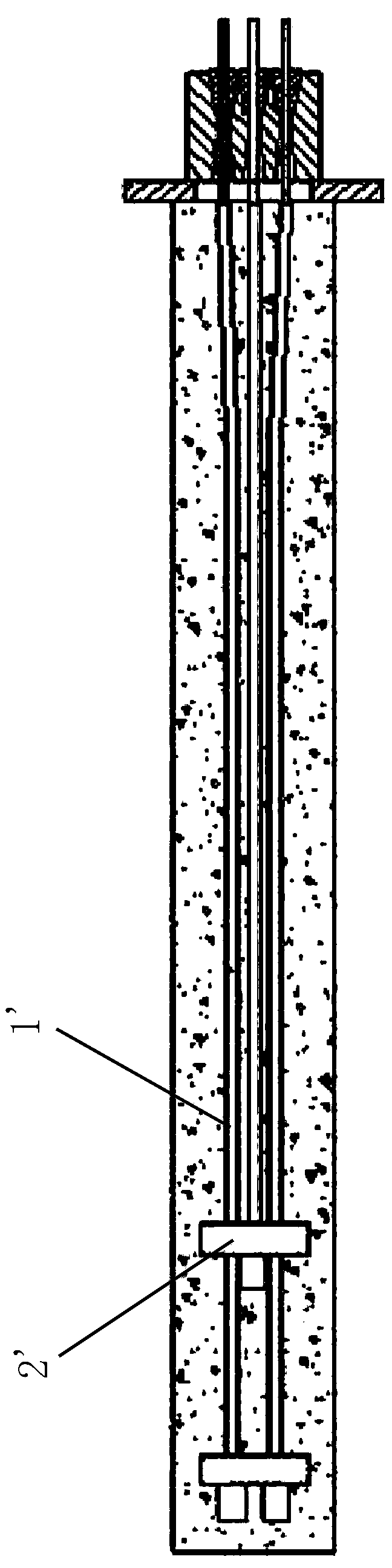

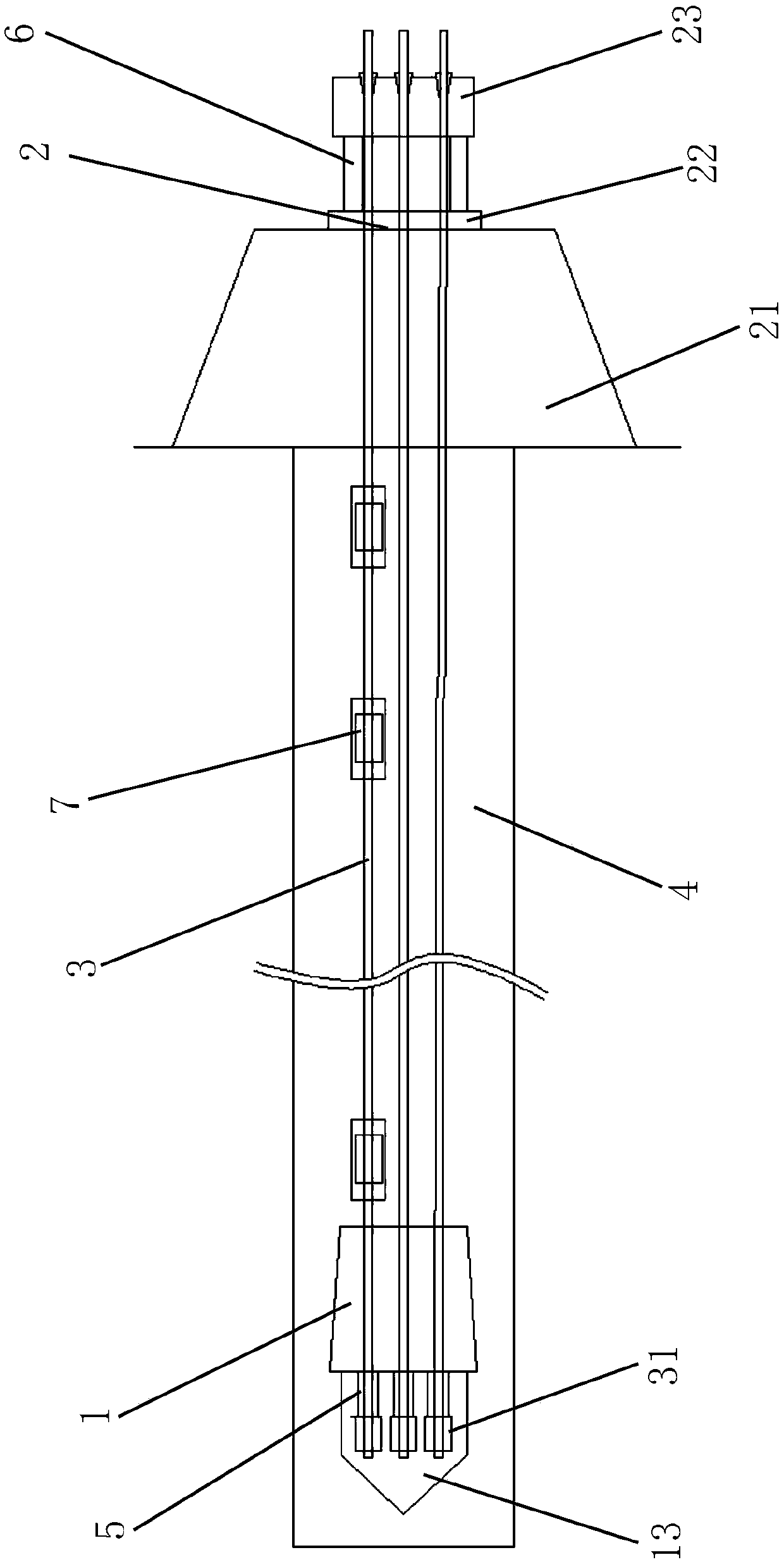

[0034] like figure 2 As shown, the present invention provides an intelligent anchor cable system suitable for rock slope support and full-range monitoring, which includes an inner anchor head 1 and an outer anchor head 2, which are fixedly connected by several steel strands 3, The 3 sets of steel strands are provided with casings filled with anti-rust grease.

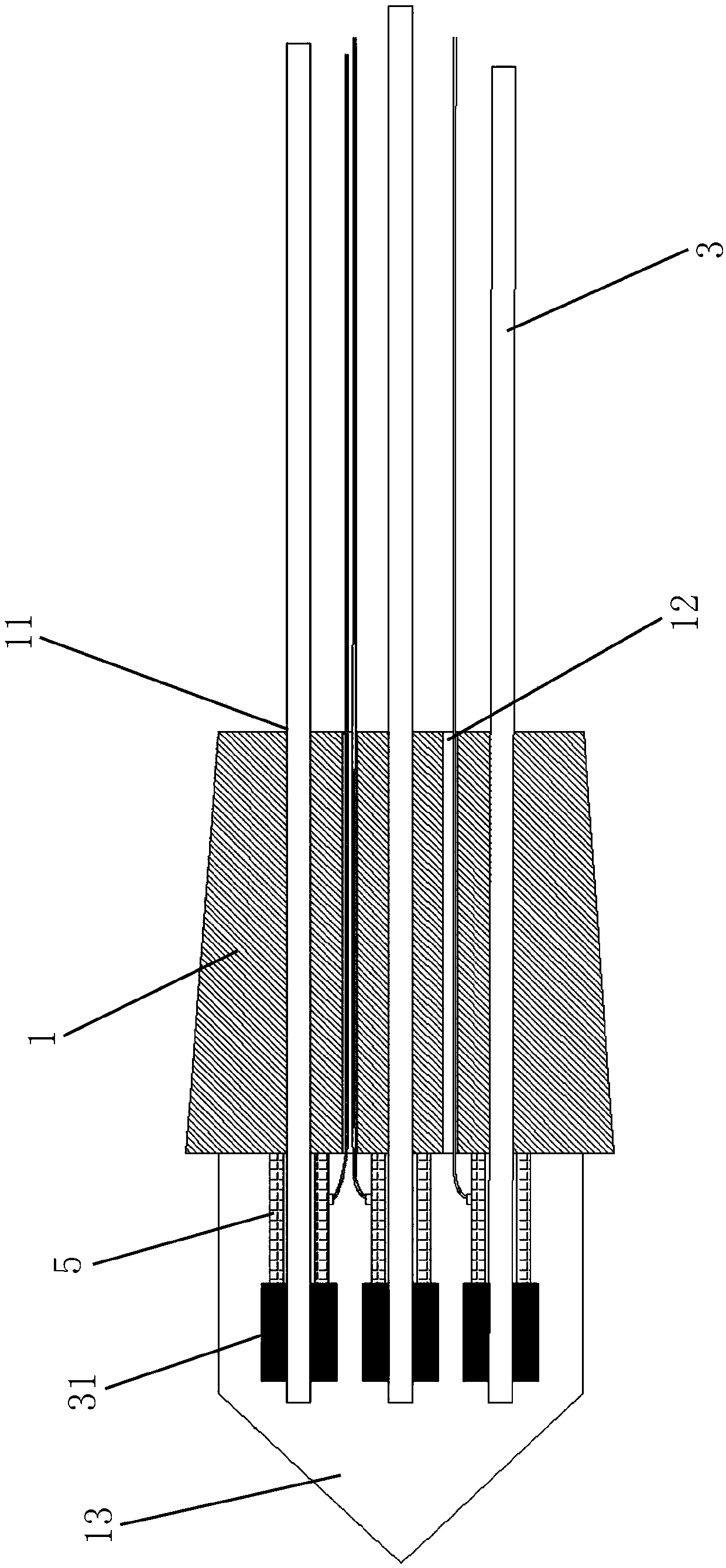

[0035] like image 3 As shown, the inner anchor head 1 is located at the inner end of the anchor cable borehole 4, through which a number of twisted wire holes 11 and wire holes 12 are provided. Each steel strand 3 is passed through the corresponding strand hole 11, and the inner end of each steel strand 3 is provided with a heading head 31, and a first measuring head is arranged between the heading head 31 and the inner end surface of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com