Test device and method for determining buoyancy of shield tunnel

A shield tunnel and model test device technology, which is applied in the field of test devices for determining the buoyancy during the excavation process of the shield tunnel, can solve the problem of making clear regulations on the anti-floating design and construction measures of the tunnel and failing to correctly reflect the construction period Tunnel anti-floating characteristics, tunnel anti-floating design and construction measures, etc., to achieve strong expansion, simple anti-sinking device, and avoid displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail through a preferred embodiment below in conjunction with the accompanying drawings.

[0027] First, make a model box, a segment lining model of a rectangular tunnel, and a set of total weight control devices for a rectangular tunnel.

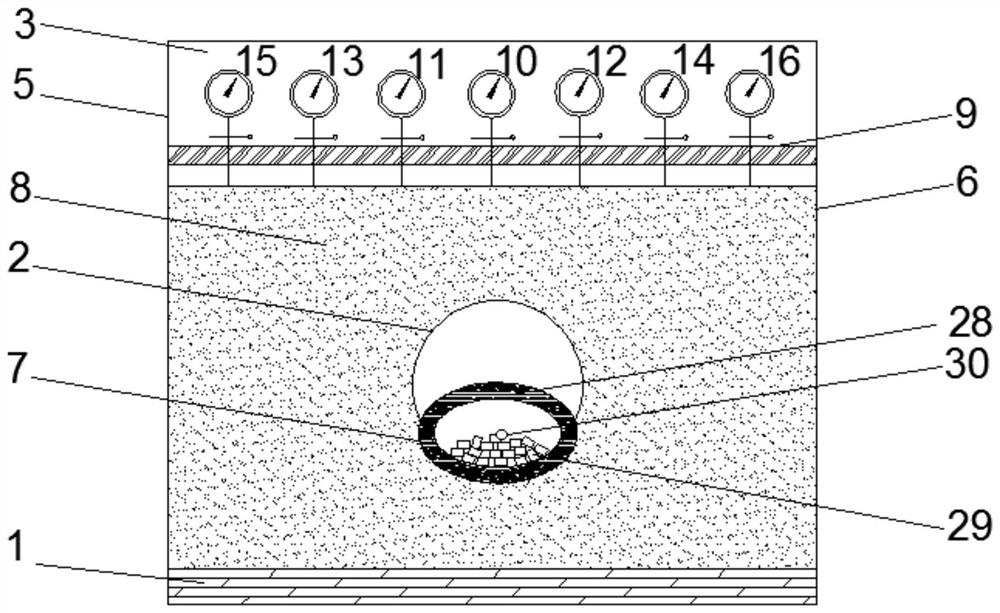

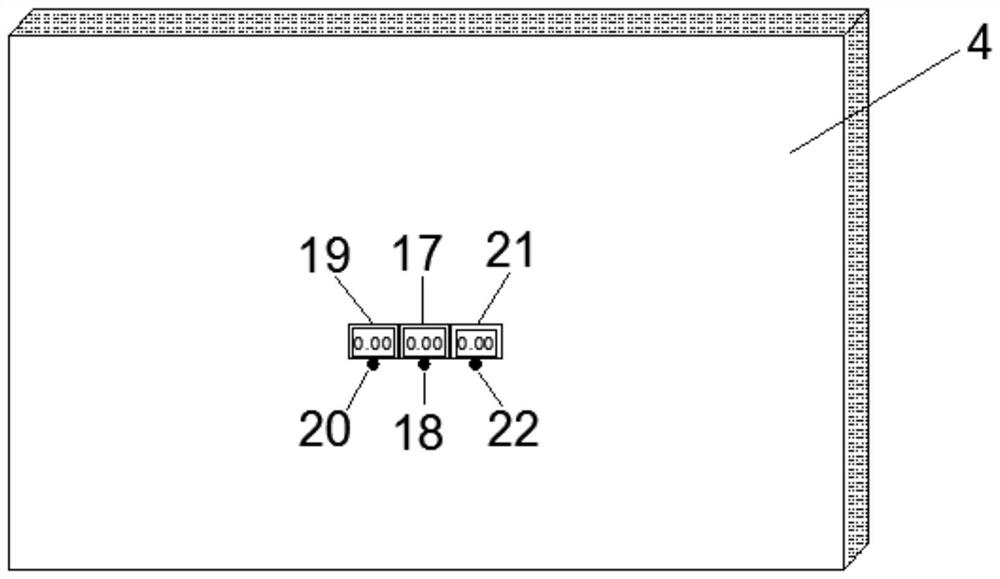

[0028] like figure 1 As shown, the shape of the model box is a cuboid, the internal space size is 2200mm×1500mm×1800mm (length×width×height), the bottom is made of a wooden board 1 of 2200mm×1500mm×30mm (length×width×thickness), and the front is 2200mm×1830mm ×20mm (length×height×thickness) toughened glass 3 with a radius of 150mm circular glass orifice 2, the center of the circular glass orifice is located in the center of the tempered glass 3, and the back is 2200mm×1830mm×20mm (length×height× thick) plank 4, the left side is a plank 5 of 1530mm×1830mm×20mm (width×height×thickness), the right side is a plank 6 of 1500mm×1830mm×20mm (length×height×thickness), the bottom and plank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com