Sewage pumping station dynamic control method and system

A technology for dynamic control and sewage pumping stations, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of low control stability of sewage pumping stations, and achieve the effects of convenient and quick adjustment, prolonging working life, and stable system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a dynamic control method for a sewage pumping station, including:

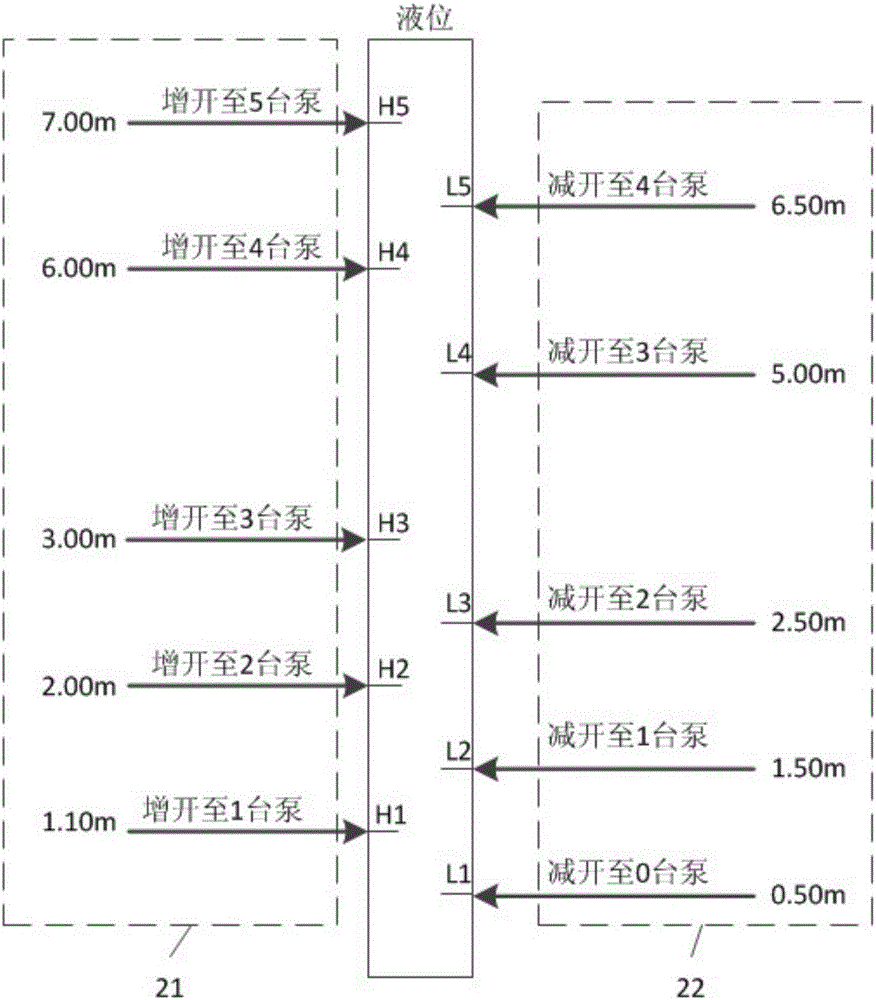

[0033] The liquid level of the upstream pipe network is divided into continuous multi-stage liquid level intervals, and a corresponding target flow rate is set for each liquid level interval, and each target flow rate corresponds to the number of water pump groups turned on.

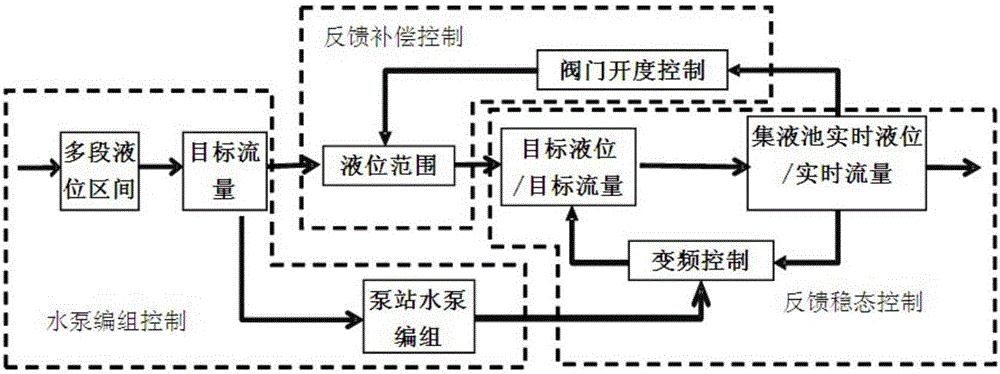

[0034] Specifically, such as figure 1 As shown, first, according to the operation of the upstream pipeline network, the liquid level range is divided into continuous multi-stage liquid level intervals, that is, the liquid level intervals are discretized to form multi-stage discrete liquid level intervals. Since the liquid level in the upstream pipe network presents different liquid level heights in different time periods, for example, during peak water consumption periods such as lunch and dinner, the liquid level in the pipe network will rise relatively, while at midnight, the pipe network will The fluid...

Embodiment 2

[0046] This embodiment is a control system corresponding to the sewage pumping station control method in Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only this embodiment will be described. Example differs from Example 1:

[0047] This embodiment provides a dynamic control system for a sewage pumping station, which is controlled by a PLC control system, and the PLC control system includes:

[0048] The water pump group control module is used to set the interval value of the continuous multi-stage liquid level interval divided by the upstream pipe network, and the target flow value set corresponding to each of the liquid level intervals, and each of the target flow values has a corresponding water pump group ; It is used to determine the liquid level interval according to the real-time liquid level of the upstream pipe network, obtain the corresponding target flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com