Steel column structure and method for controlling allowable misalignment thereof

A technology that allows errors and steel columns, applied in the directions of columns, pillars, piers, etc., can solve the problems of difficulty in regulation, hidden dangers, easy installation errors, etc., to achieve the effect of improving waterproofing and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

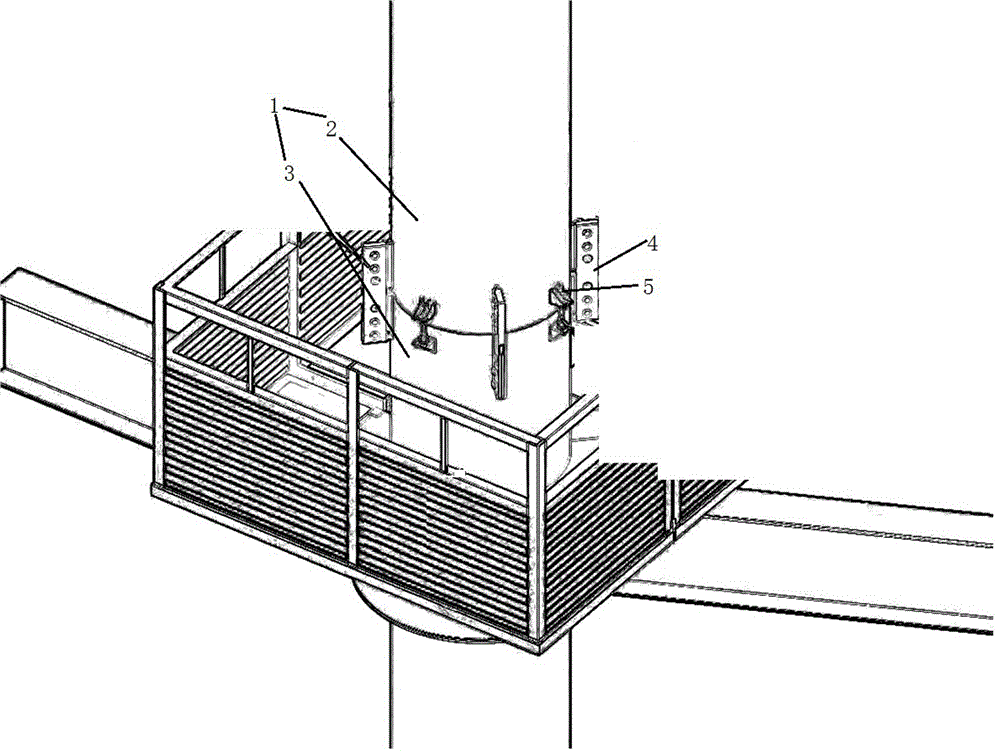

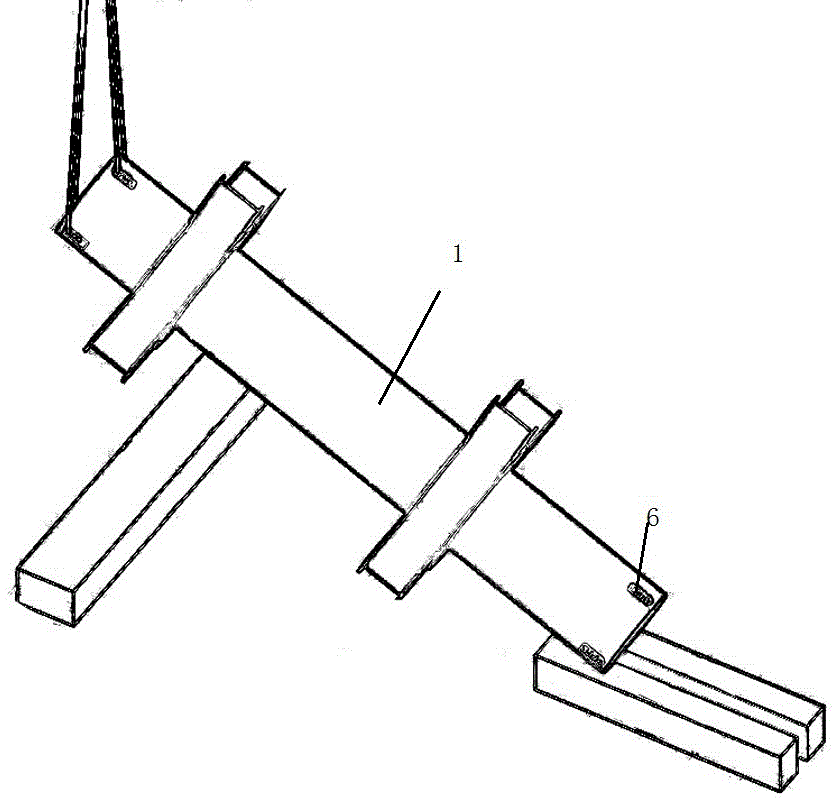

[0040] Such as Figure 1 to Figure 4 The shown steel column structure includes: a column body 1, the column body 1 is composed of an upper section column 2 and a lower section column 3, and the upper section column 2 and the lower section column 3 are connected by a connecting plate 4 A jack 5 is provided between the connecting plate 4 on the upper section column 2 and the lower section column 3 , and connecting ear plates 6 are provided at both ends of the upper section column 2 .

[0041] In this embodiment, a partition 7 is provided on the top of the upper section column 2 , and a rainproof shed 8 is provided above the partition 7 .

[0042] Corbels are arranged around the cylinder 1 in this embodiment, and the corners of the corbels are arc-shaped.

[0043] In the present embodiment, the rainproof shed 8 is provided with three anti-cloths.

[0044] In this embodiment, the jack 5 is in the form of a right triangle, and the jacks 5 on the upper column 2 and the lower colum...

Embodiment 2

[0046] In this embodiment, a steel column structure as shown in the figure includes: a column body 1, the column body 1 is composed of an upper section column 2 and a lower section column 3, and the upper section column 2 and the lower section column 3 The upper section column 2 and the lower section column 3 are provided with a jack 5 between the connection plates 4 , and the two ends of the upper section column 2 are provided with connecting ear plates 6 .

[0047] In this embodiment, a partition 7 is provided on the top of the upper section column 2 , and a rainproof shed 8 is provided above the partition 7 .

[0048] Corbels are arranged around the cylinder 1 in this embodiment, and the corners of the corbels are arc-shaped.

[0049] In the present embodiment, the rainproof shed 8 is provided with three anti-cloths.

[0050] In this embodiment, the jack 5 is in the form of a right triangle, and the jacks 5 on the upper column 2 and the lower column 3 cooperate with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com