Automatic grooving machine for water and electricity decoration

A slotting machine, automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of manual operation, low efficiency, complicated operation, etc., to achieve the effect of simple and labor-saving operation, reducing labor intensity and reducing injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

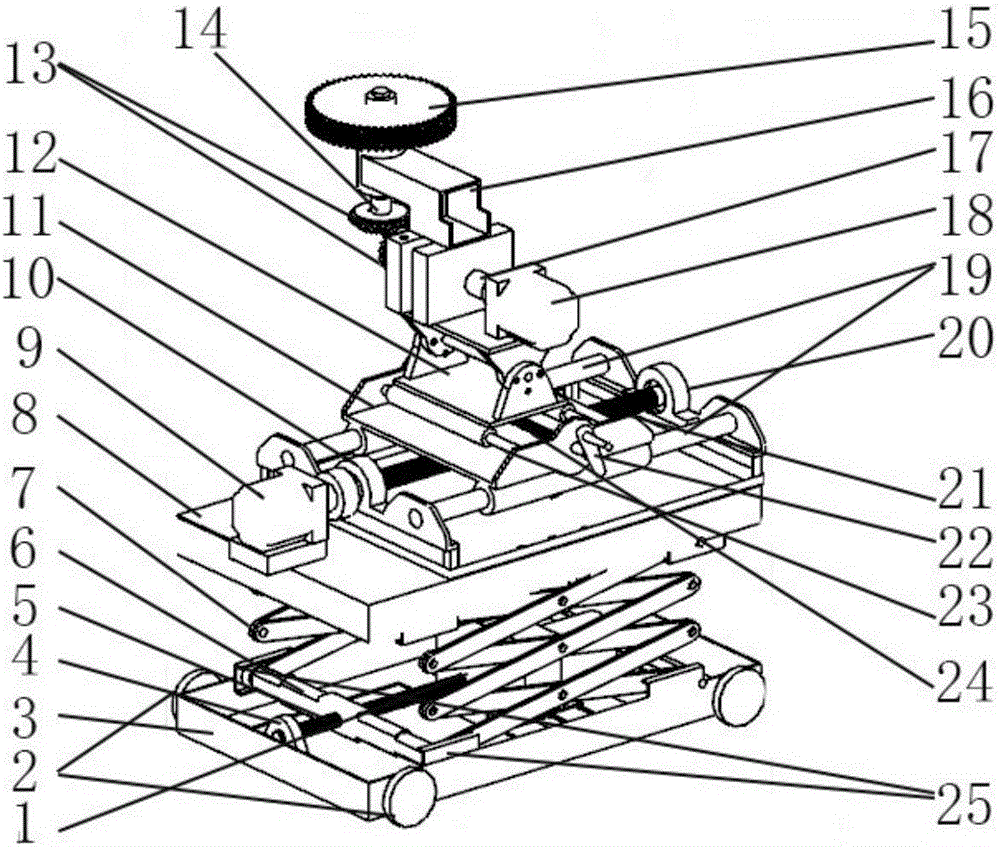

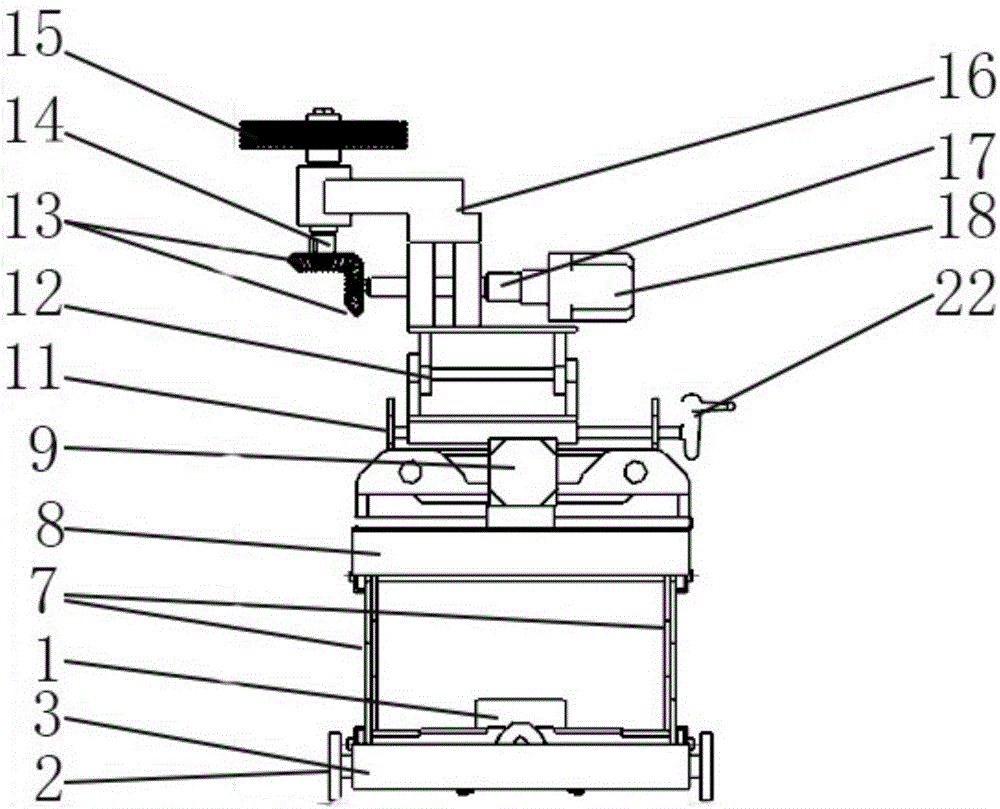

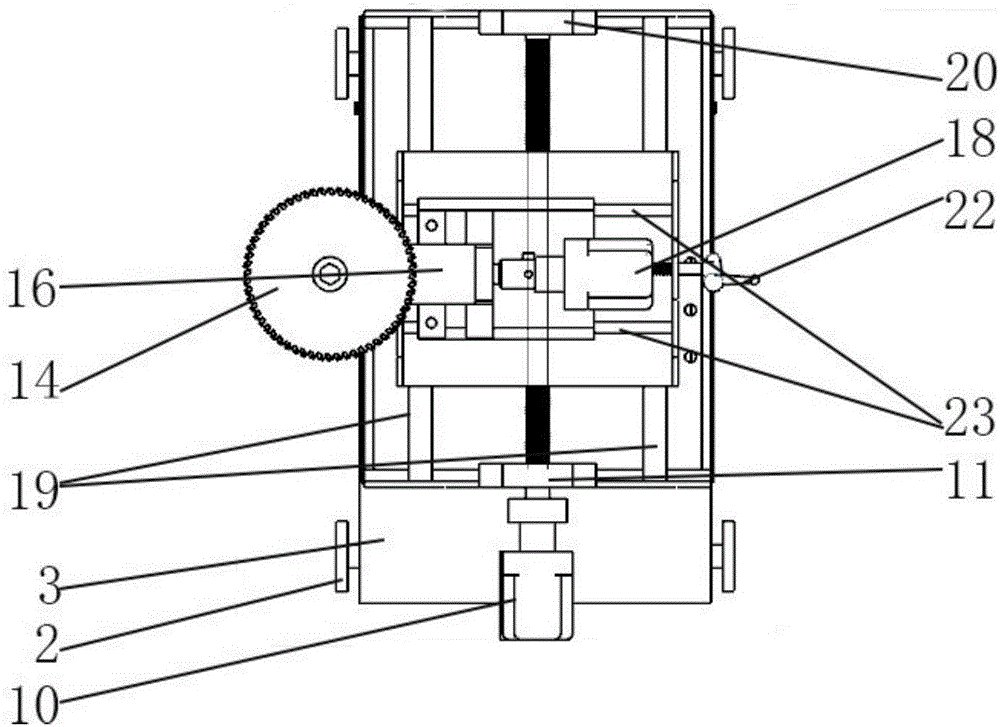

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0026] like Figure 1 to Figure 8 As shown, the automatic grooving machine for hydropower decoration of the present invention includes a scissor lift mechanism, a horizontal feed mechanism, a longitudinal feed mechanism and a multi-directional grooving mechanism. The specific structure and connection method are:

[0027] like Figure 1 to Figure 4 As shown, the scissor lift mechanism includes a first motor 1, a first screw shaft 5, a bearing seat 4, a base bracket 3, a base wheel 2, a transmission shaft 6, double guide grooves 25, scissors 7 and a working platform 8. The base bracket 3 is equipped with four base wheels 2, the first motor 1, the first screw shaft 5, and the bearing seat 4 are connected in sequence and installed on the base bracket 3, and the double guide grooves 25 are welded on the base bracket 3, and the transmission T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com