Grouting device

A grouting device and grouting technology, applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of cleaning filter grouting material waste, easy blockage of filter screen, low construction efficiency, etc., to achieve guaranteed Improve construction quality, improve grouting efficiency, and prevent filter blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

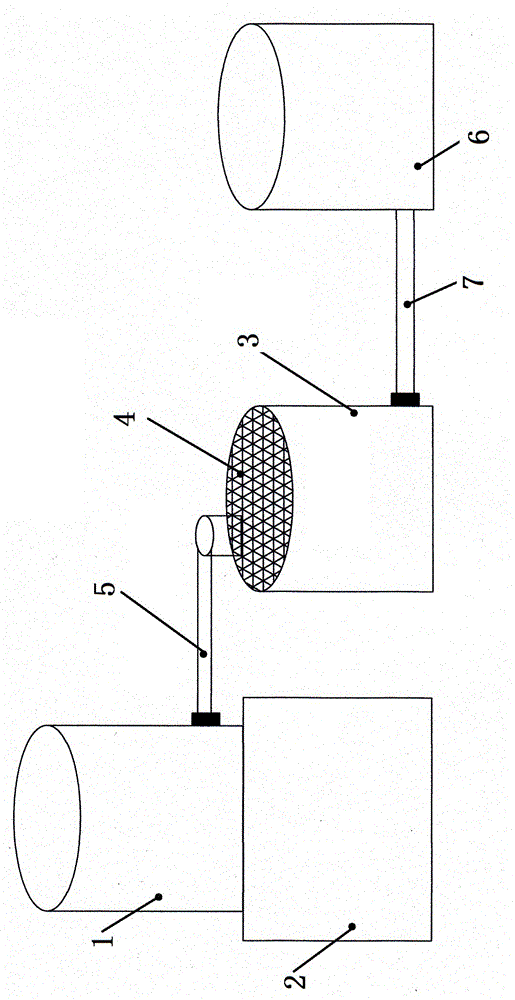

[0012] refer to figure 1 , it comprises a first mixer 1, said first mixer is arranged on a support 2, a second mixer 3 is established near the first mixer, and the discharge opening of said first mixer is higher than the feeding port of the second mixer, Set filter screen 4 below the feeding port of the second mixer, be connected by connecting pipe 5 between the feeding port of the first mixer and the feeding port of the second mixer, the discharging port of the second mixer and the grouting machine 6 The feeding port is connected through the slurry delivery pipe 7. The material for grouting is stirred in the first mixer, and after the mixing is qualified, it flows into the second mixer through the connecting pipe, and continues to stir in the second mixer, and at the same time, the slurry is sent to the grouting machine through the slurry delivery pipe. One mixer stirs the next plate of slurry, and the second mixer delivers the slurry while stirring, and the grouting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com