Antitheft lock

A technology of anti-theft lock and lock body, which is applied in the field of anti-theft locks, can solve the problems that the product does not break through the user's intelligent needs, cannot stimulate the user's desire to use, and the structure of the anti-theft lock is cumbersome. The effect of size standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

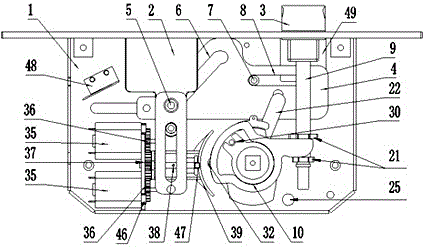

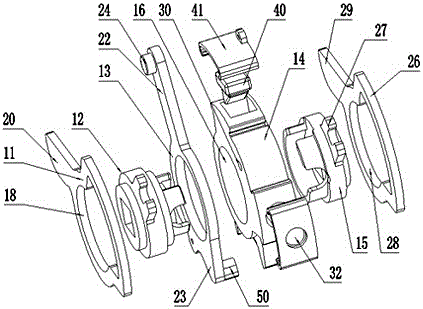

[0028] Embodiment 1: The lock bolt actuator assembly 10 includes an inner latch bolt shifting piece 11, an inner clutch shaft 12, a clutch core 14 and an outer clutch shaft 15, and the inner latch bolt shifting piece 11 faces the lock inner casing, the outer The clutch shaft 15 faces the lock body shell, and the middle part of the clutch movement 14 is provided with a through hole 16. The outside of the clutch movement 14 cooperates with the outer clutch shaft 15, and the inner side of the outer clutch shaft 15 is inserted into the clutch. In the through hole 16 of the core 14, the outer opening of the outer clutch rotating shaft 15 is a square hole matched with the outer handle; the inner side of the clutch movement 14 is sequentially provided with an inner clutch rotating shaft 12 and an inner oblique tongue toggle piece 11, The outer platform circle of the inner clutch rotating shaft 12 is inserted in the through hole 16 of the clutch core 14, and the outer diameter of the m...

Embodiment 2

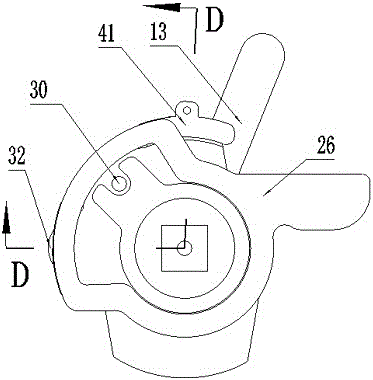

[0029] Embodiment 2: On the basis of Embodiment 1, an outer oblique tongue toggle piece 26 is set on the step circle of the outer end surface of the outer clutch shaft 15, and a second toggle is provided on the outer circular surface of the outer clutch shaft 26. Block 27, the inner hole of the outer oblique tongue shifting piece 26 is provided with an arc-shaped groove 28, and the second shifting block 27 is clamped in the arc-shaped groove 28 of the outer oblique tongue moving piece 26, wherein the arc-shaped groove There is also a space avoidance margin, that is, the radian of the arc groove is greater than the outer arc of the second toggle block, and the second toggle block can slide in the arc groove, so that the outer handle can be pressed down to drive the outer clutch shaft to rotate. Lifting the outer handle will not be reversed due to the margin of avoidance; the outer circle of the outer oblique tongue shifting piece 26 is provided with a second shift fork 29, and t...

Embodiment 3

[0030] Embodiment 3: Improvement is made on the basis of Embodiment 2. There is also a main tongue shifting element 13 between the inner clutch shaft 12 and the clutch core 14, and the main tongue shifting element 13 is set and sleeved in the inner clutch On the intermediate table circle 17 outside the rotating shaft 12, the outer circle of the main tongue toggle element 13 is radially and symmetrically provided with a toggle arm 22 and a pivot arm 23, and the end of the toggle arm 22 is provided with the main tongue The protruding post 24 matched with the vertical long waist hole on the tongue push piece 4, the end of the rotating arm 23 is provided with a boss 50, and the outer circle of the clutch movement 14 is provided with a limit groove cooperating with the boss 50, The lower end of the main tongue toggling element 13 is connected to the torsion spring positioning post 25 in the lock body 1 through a torsion spring; The protruding posts are arranged opposite to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com