Blasting mining to fully mechanized mining process of deeply inclined coal seam breaking roof

A technology of broken roof and large inclination angle, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc. It can solve problems such as difficult roadway support, increased roof fragmentation, and difficult roof management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Coal mining mine conditions: The coal seam of this mining face is a medium-thick coal seam with a large dip angle, and the dip angle is 34°-48°, with an average of 40°. It is the broken roof zone of the coal seam with large dip angle.

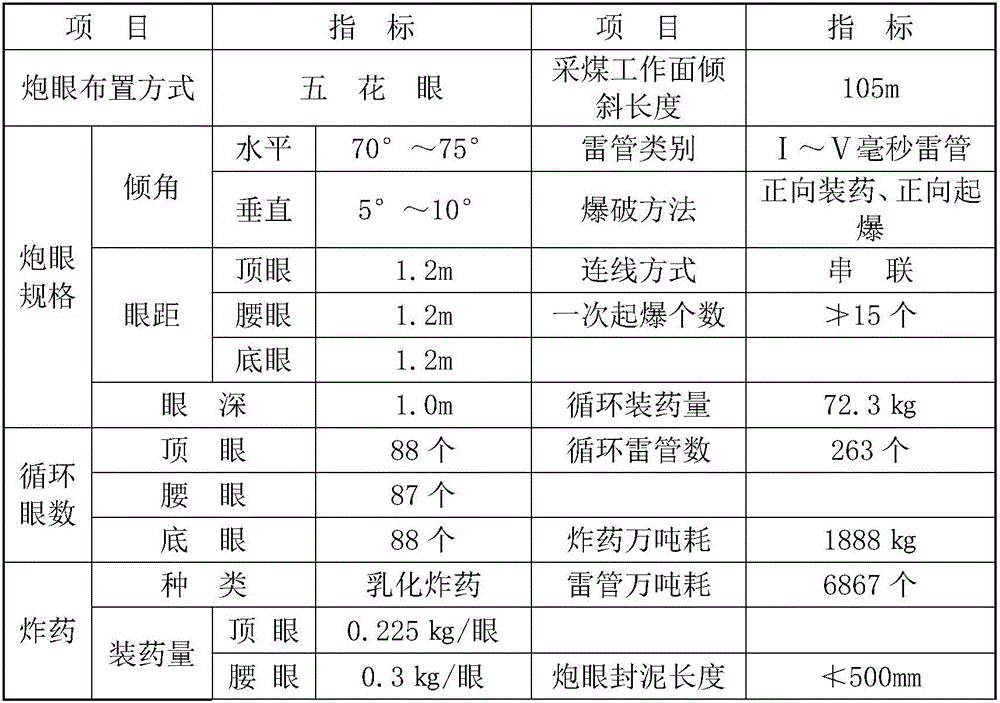

[0048] Set mining parameters as follows:

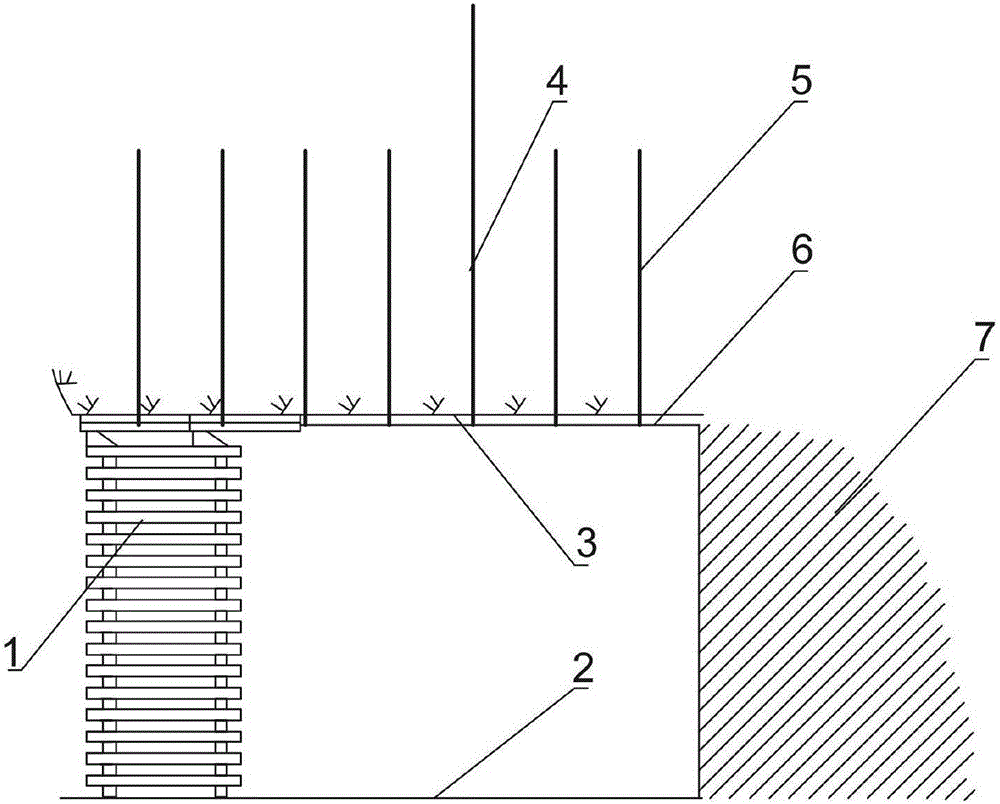

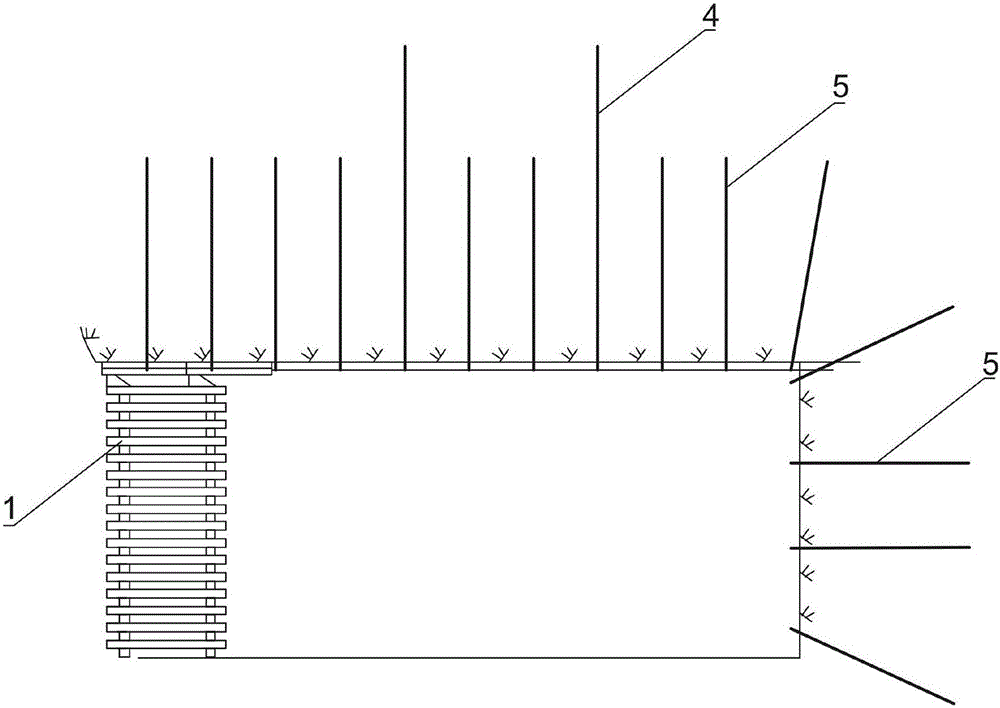

[0049]In order to ensure safe production and increase unit yield, it is determined that the coal mining face adopts the method of segmented and intensive coal mining in the long wall of the downward pseudo-slant direction. Inclined state: segmental dense spacing (pseudo-slope distance) 3.0m, dense column spacing 0.3m, dense cushion 0.5m high, 0.5m thick, dense climbing (upgrade angle) 5-10°.

[0050] Blasting process stage:

[0051] The average mining height of the coal mining face is 2.65m. Cycle progress: 1.0m. Use blasting to drop coal.

[0052] Blast hole layout and blasting method: ① Blast hole layout: use streaky hole layout. ② Blasting method: adopt millisecond detonator series conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com