Automatic drainage control system

A control system and automatic drainage technology, applied in drainage, pump control, machine/engine, etc., can solve the problems of motor idling and burning motor, drainage system automation degree is not high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

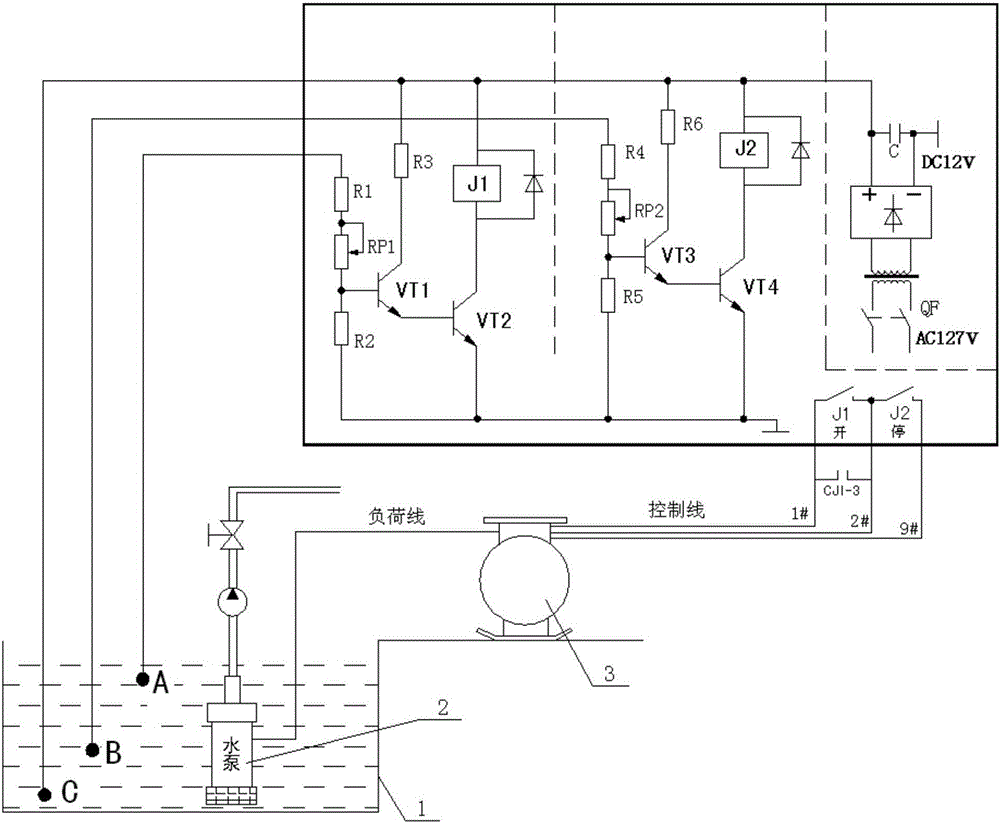

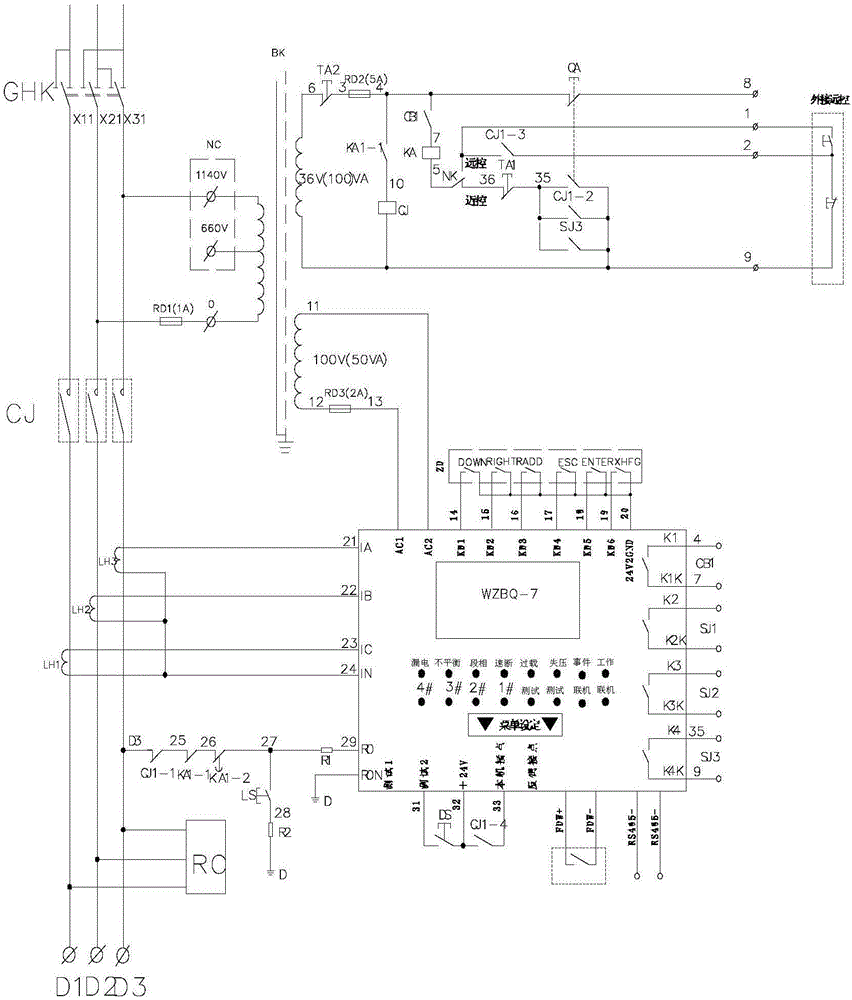

[0024] Such as figure 1 As shown, an automatic drainage control system includes a magnetic starter, a power module, an electrode sensor, a relay J1, a relay J2, a first control loop, and a second control loop. The magnetic starter 3 is a switch for controlling the water pump 2, and the relay The normally open contact of J1 and the normally open contact of the relay J2 are connected in series and respectively in parallel on the three pins of the magnetic starter 3 .

[0025] The two ends of the coil of the relay J1 and the coil of the relay J2 are respectively connected with anti-reverse diodes in parallel, and the output terminals of the anti-reverse diodes are connected with the output terminals of the power supply.

[0026] The electrode sensor includes a lower limit water level sensor, an upper limit water level sensor and a third water level sensor. The horizontal heights of the third water level sensor, the lower limit water level sensor and the upper limit water level s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com