Hot plate temperature-equalization mixing-free turbine blade cooling device and method

A technology of turbine blade and cooling device, which is applied in the field of hot plate uniform temperature non-mixing turbine blade cooling device, which can solve the complex flow and flow field structure of the cascade flow channel, uneven temperature of the turbine blade, and difficulty in maintaining the integrity of the blade, etc. problem, achieve the effect of improving cooling efficiency, reducing thermal stress and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

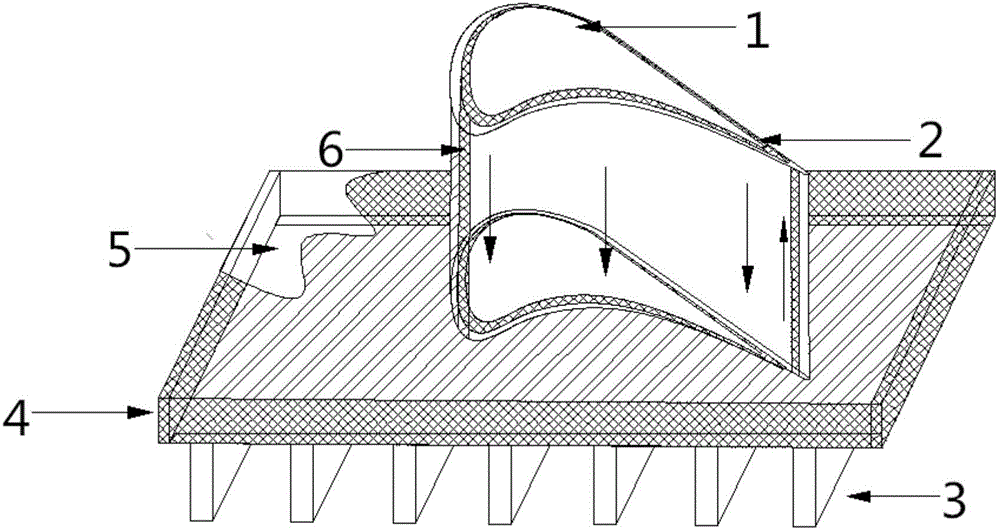

[0015] A hot plate uniform temperature non-mixing turbine blade cooling device comprises two parts: a uniform temperature hot plate and a turbine blade. The uniform temperature hot plate includes an evaporation section 6, a condensation section 4 and an end cover 5. The evaporation section 6 is inside the turbine blade, and the wire mesh 2 of the hot plate is on the outer ring of the hot plate, which is equivalent to the liquid-absorbing core of the hot plate, and the steam channel 1 Inside the vapor chamber, the outer surface of the turbine blade is covered by a thermal barrier coating, the turbine blade is connected to the end cover 5, and the end cover closes the condensation section 4 of the vapor chamber, except for the wall surface connected to the turbine blade in the condensation section In addition, wire mesh is distributed on all other walls, and ribs 3 are arranged outside the condensation section.

[0016] The method for cooling the turbine blades by using the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com