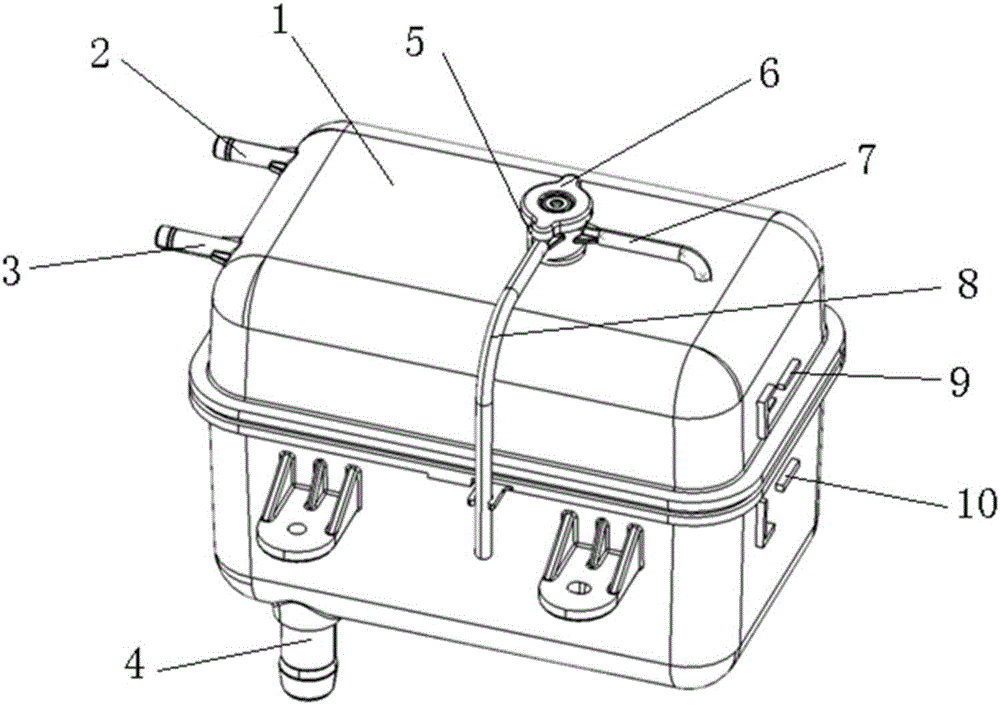

Expansion tank and processing method

A technology for expansion kettles and water pipe joints, which is applied in the cooling of engine components, machines/engines, and engines. It can solve the problems of coolant corrosion and scale hazards that cannot be discharged out of the system, so as to avoid component failures and ensure long-lasting safety and high efficiency. The effect of running and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

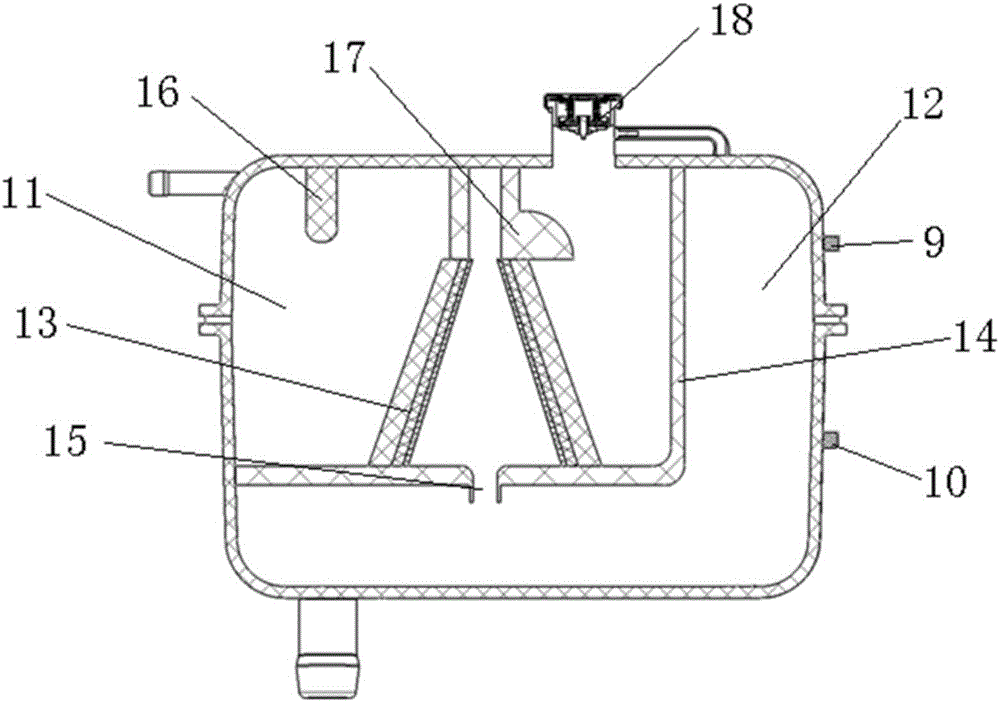

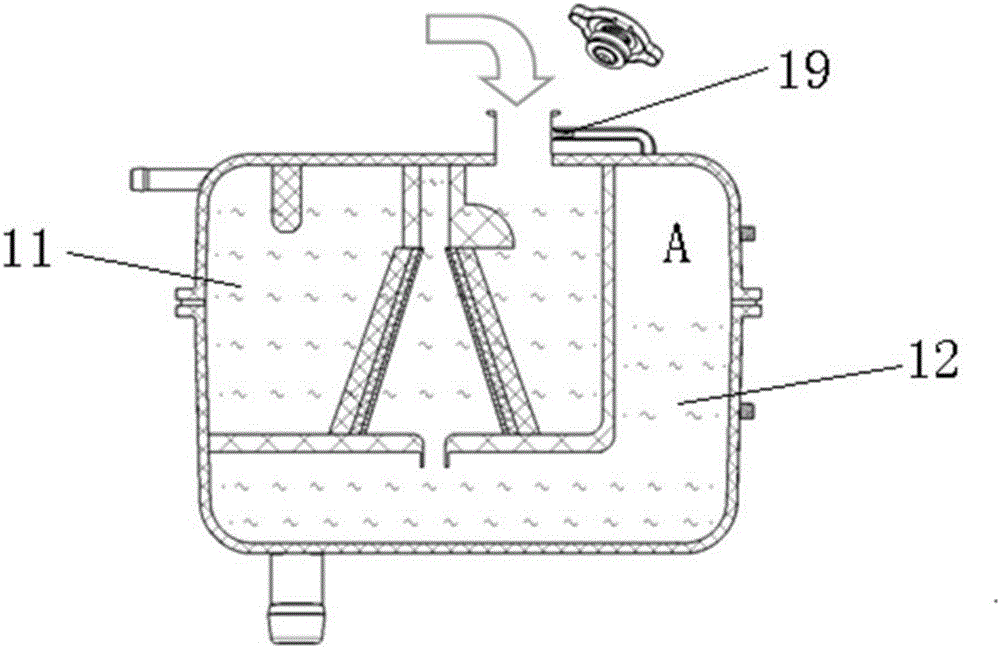

[0040] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0041] The role of the expansion kettle of this application:

[0042] Rust and scale removal: The polymer composite filter paper layer physically absorbs the rust and scale generated in the cooling system, avoiding the phenomenon of clogging pipes, ensuring high-efficiency heat dissipation performance, and reducing fuel consumption.

[0043] Eliminate potential risks: through the anion-cation exchange chemical action, before the formation of rust and scale, calcium, magnesium and iron ions in the cooling liquid are removed to form the deionized water required by the system, avoiding the potential risk of rust and scale formation in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com