Water outlet pipe assembly of engine

A water outlet pipe and engine technology, applied in engine components, machines/engines, engine cooling, etc., can solve the problems of high water leakage probability and complex cooling circuit, and achieve the effect of reducing water leakage probability, low cost and reducing development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

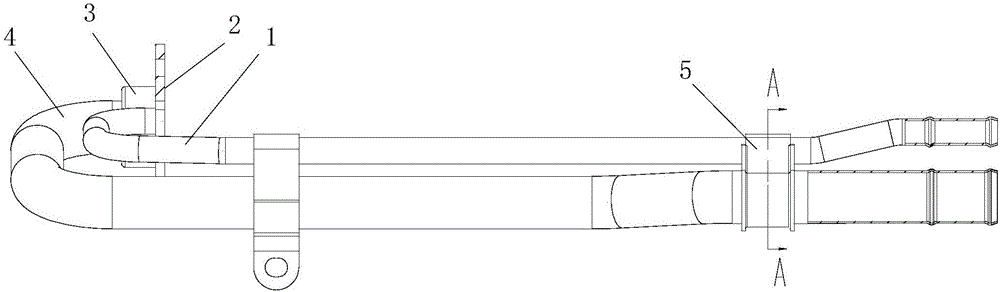

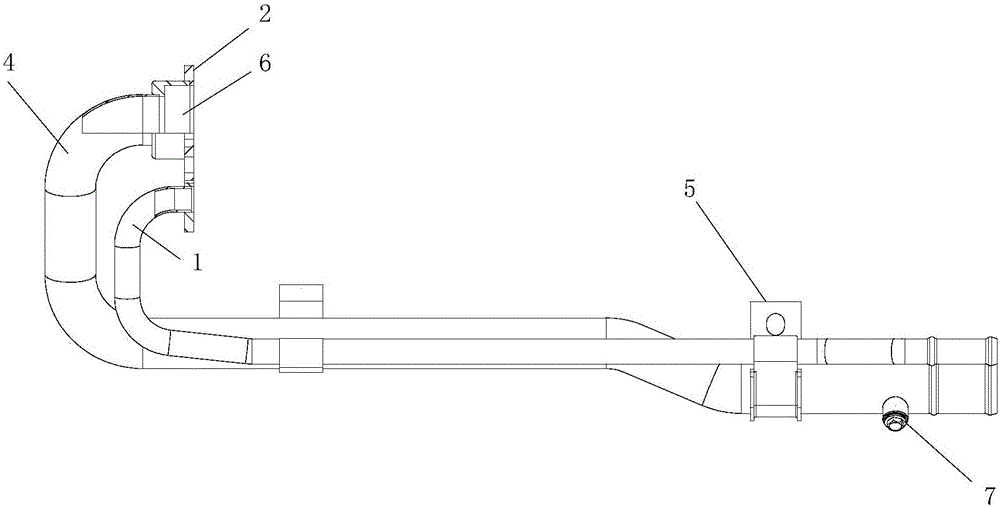

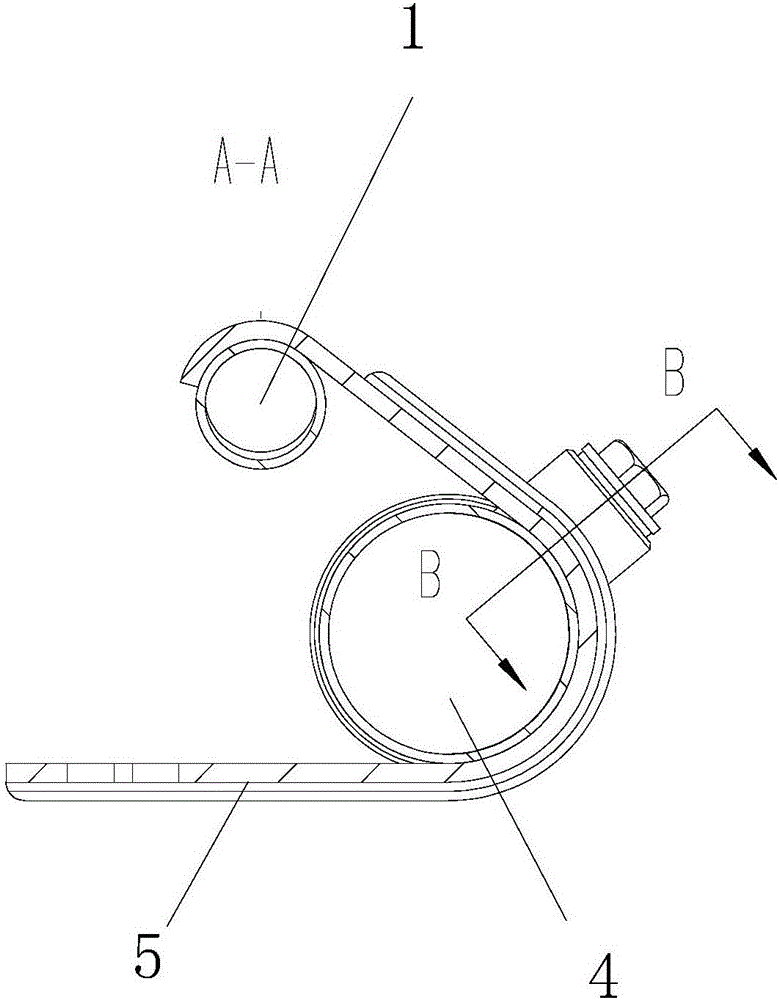

[0017] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, the engine outlet pipe assembly of this embodiment includes a large circulation pipe 4 and a small circulation pipe 1 that can be used as a warm air return pipe; the inlet end of the large circulation pipe 4 and the inlet end of the small circulation pipe 1 are connected to a The common flange 2 is connected to the engine block through the common flange 2; in this embodiment, the large circulation pipe 4 and the small circulation pipe 1 are connected to the engine block through the common flange 2 and communicated with the water outlet chamber on the cylinder block , the cooling water in the cylinder enters the water outlet chamber and flows to the large circulation pipe 4 or the small circulation pipe 1 under the control of the thermostat. At the same time, the coolant flowing out of the heater can also flow into the water outlet chamber and flow through the small circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com