Multi-cavity fluid power diaphragm pump system

A fluid power, diaphragm pump technology, applied in the components of pumping devices for elastic fluids, liquid fuel engines, pumps, etc., can solve problems such as increasing starting pressure, increasing diaphragm strength, and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

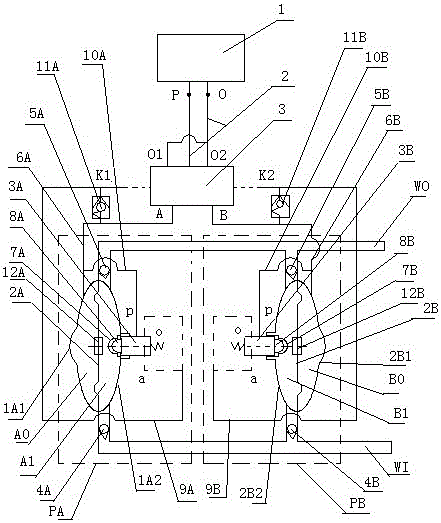

[0050] The first embodiment, with figure 1 It is a system diagram of an air-controlled multi-chamber fluid dynamic diaphragm pump with the delivery chamber close to the inner side and the signal valve installed separately. It consists of paired single-acting diaphragm pumps PA, PB, pneumatic directional control valve 3, Unicom pipeline 2, air compressor 1, etc.; each single-acting diaphragm pump includes pump housings 1A1, 1A2 (2B1, 2B2), and the The working medium and the conveying medium are separated to form the corresponding working chamber AO (BO) and the diaphragm or piston 2A (2B) of the conveying chamber A1 (B1), and the direct-acting one-way machine-controlled fluid pressure signal valve installed on the conveying chamber 3A (3B), feed check valve 4A (4B), discharge check valve 5A (5B), inlet and outlet flow pipe 6A (6B) installed on the working chamber AO (BO), installed in the delivery chamber A1 (B1 ) on the inner wall of the pump housing and sleeved on the trigge...

no. 2 example

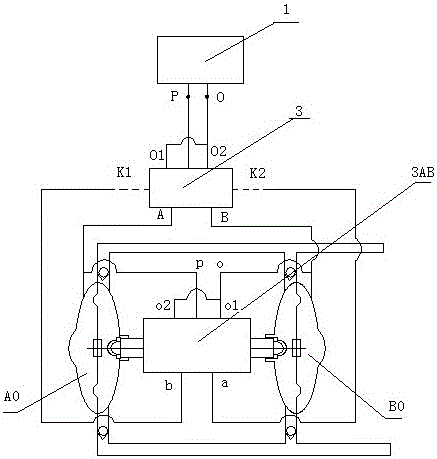

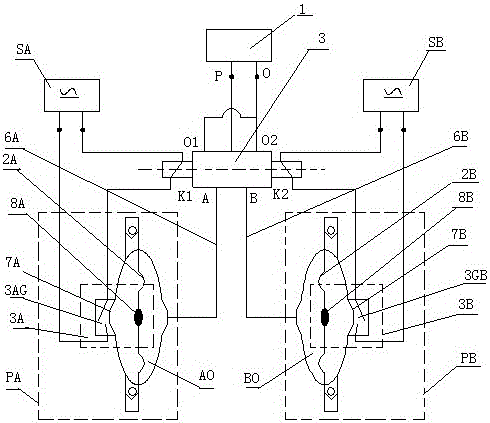

[0053] second embodiment, figure 2 It is a system diagram of an air-controlled multi-chamber hydrodynamic diaphragm pump with the conveying chamber close to the inner side and the signal valve integrally installed in the present invention, figure 2 and figure 1 The main difference between them is the pilot signal valve 3AB and its connection relationship. Pilot signal valve 3AB is a two-position five-way pilot valve with two-position mechanical control. image 3 The A port of the directional control valve 3 is connected with the working chamber AO, and the B port is connected with the working chamber BO; the A port of the directional control valve 3 is also connected with the p port of the pilot signal valve 3AB, and the B port is also connected with the pilot signal valve 3AB. After o1 and o2 are connected, the o port is connected; the b port of the pilot signal valve 3AB is connected with the control port K1 of the directional control valve 3, and the a port of the pilot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com