Spiral nut for manufacturing luggage

A technology for rotating nuts and bags, which is applied in the direction of nuts, bolts, threaded fasteners, etc., which can solve the problems of shortening the service life of bolts, damage, and easy corrosion, etc., and achieve the effect of prolonging service life and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

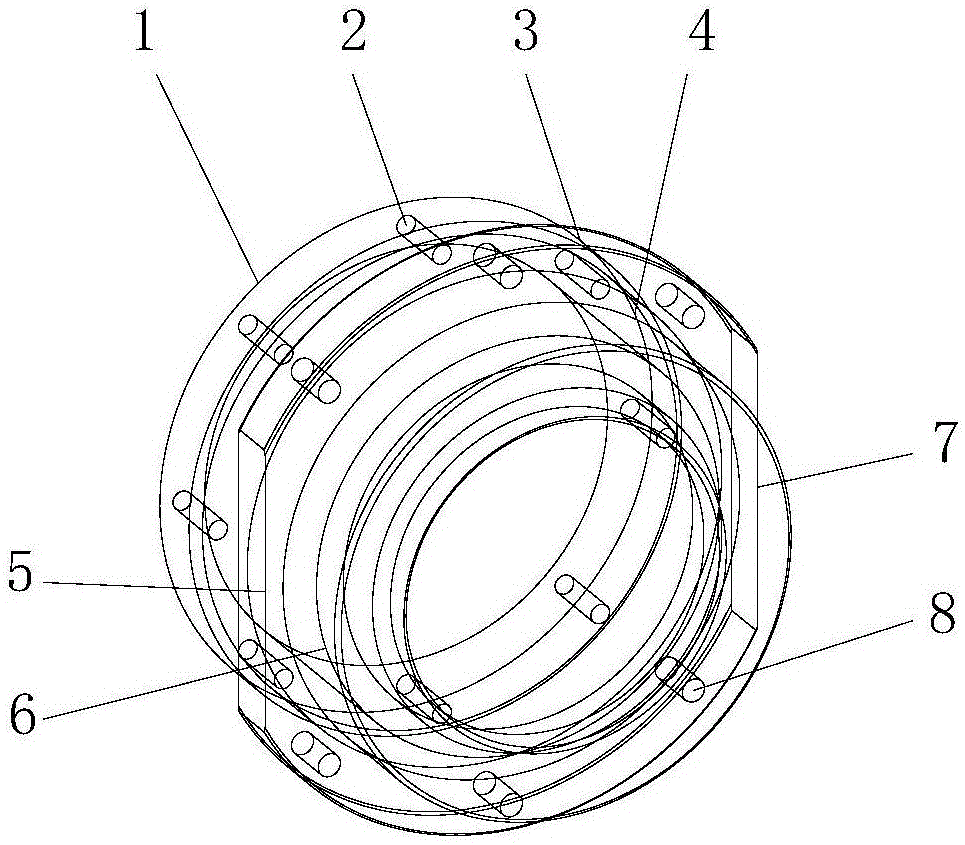

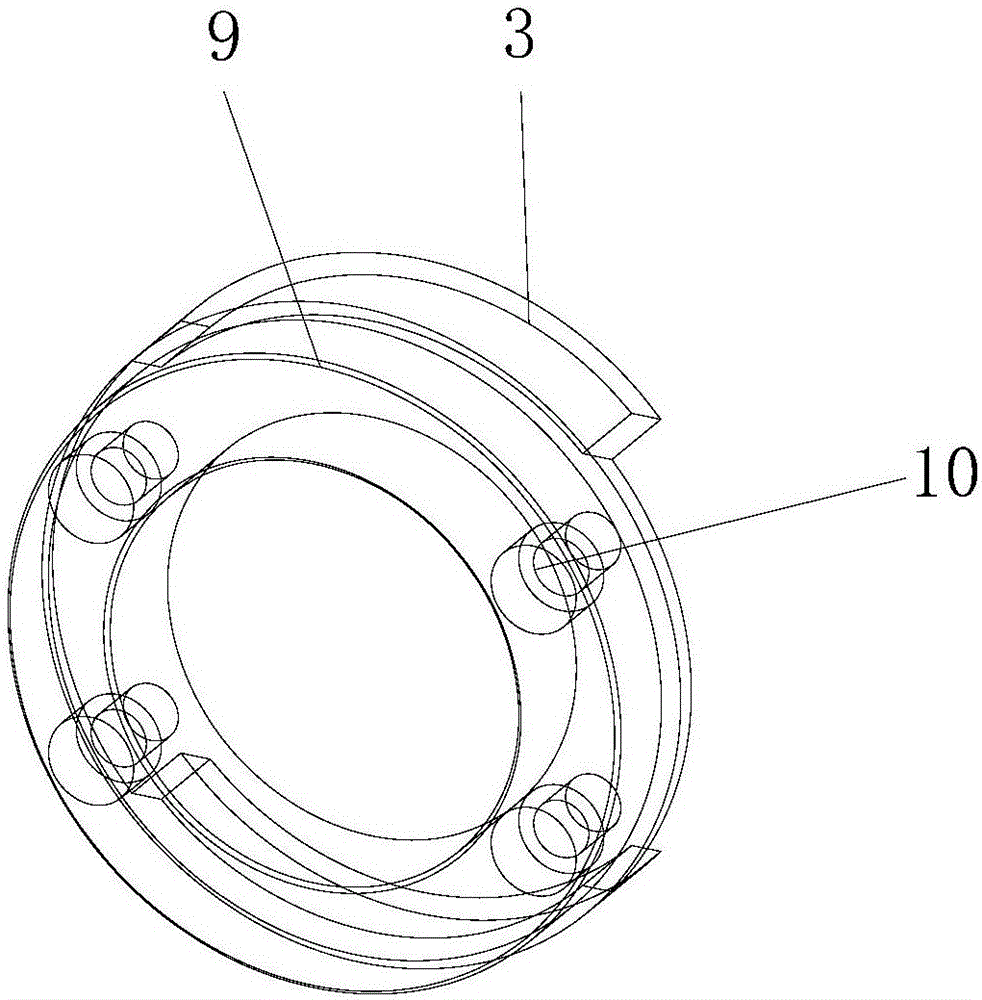

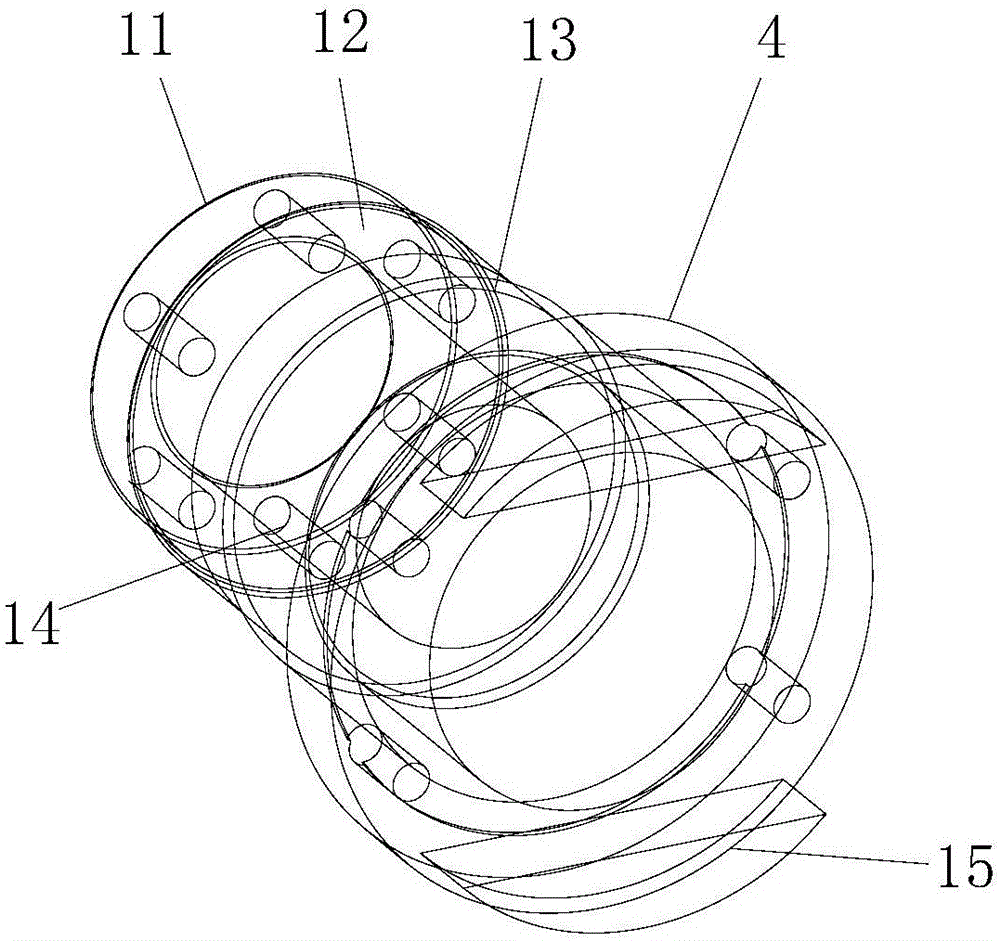

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0017] Such as Figure 1-5 As shown, a rotating nut used for luggage manufacturing includes a nut body 1, on which a housing 2 is arranged, the housing 2 is composed of an end cover 3 and an end seal 4, and the outer side of the housing 2 is provided with an inner The lining 7 is provided with a hole 8 on the lining 7, a threaded segment 6 is provided between the end seal 4 and the lining 7, and a plane groove 5 is provided on the side of the end seal 4, and a mounting ring 9 is provided on the end cover 3, and the installation The ring 9 is provided with a mounting hole 10, and the outer side of the end seal 4 is equipped with a case 11, and the case 11 is composed of a circular cover 12 and a side wall 13, and the case 11 is provided with a movable gasket 14, and the end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com