Oil storage chain wheel

A sprocket and lubricating oil technology, applied in belt/chain/gear, gear lubrication/cooling, portable lifting device, etc., can solve the problems of no storage of sprockets, inconvenient use, etc., and achieve the effect of good lubrication effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

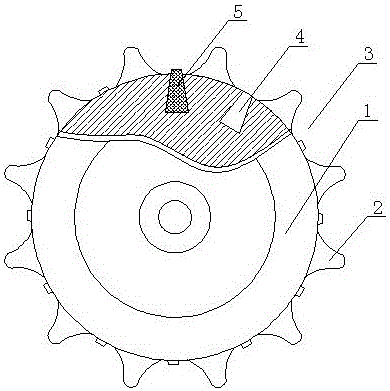

[0013] Such as figure 1 As shown, an oil storage sprocket, including a sprocket body 1, has a tooth portion 2 around the sprocket body, and a “U”-shaped groove 3 in the middle of the tooth portion; its feature is: the sprocket body There is a blind hole 4 at the groove, and a sponge block 5 full of lubricating oil matching the blind hole is placed in the blind hole.

[0014] In this way, the sponge block can continuously supply lubricating oil to the chain, reducing the number of times of adding lubricating oil.

[0015] Furthermore, the blind hole has a structure with a large inside and a small opening.

[0016] Further, the outer end of the sponge block is higher than the upper edge of the groove. In use, the chain presses the upper end of the sponge block, and the sponge block will retract into the blind hole without damaging the sponge block. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com