Automobile lamp assembly and manufacturing method thereof

A manufacturing method and a technology of car lights, which are applied in the direction of headlights, vehicle parts, motor vehicles, etc., can solve the problems of poor practicability, slow fog dispersing time, poor anti-fog effect car lights, etc., and achieve good intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

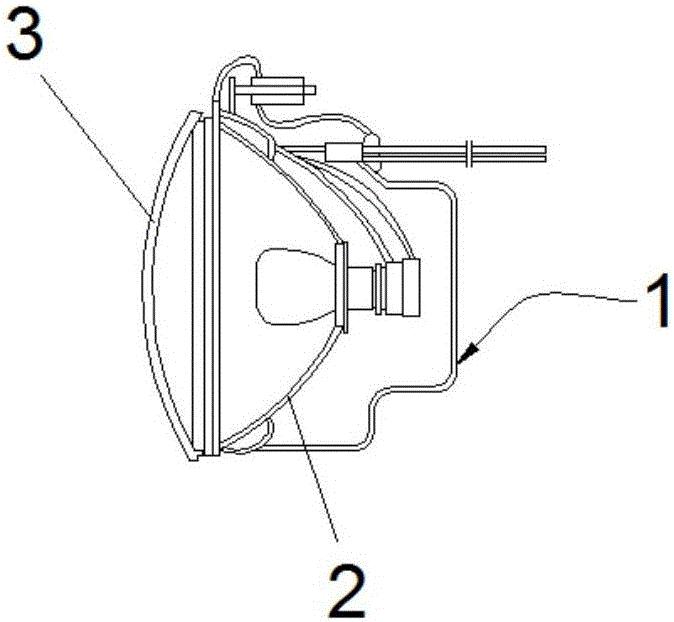

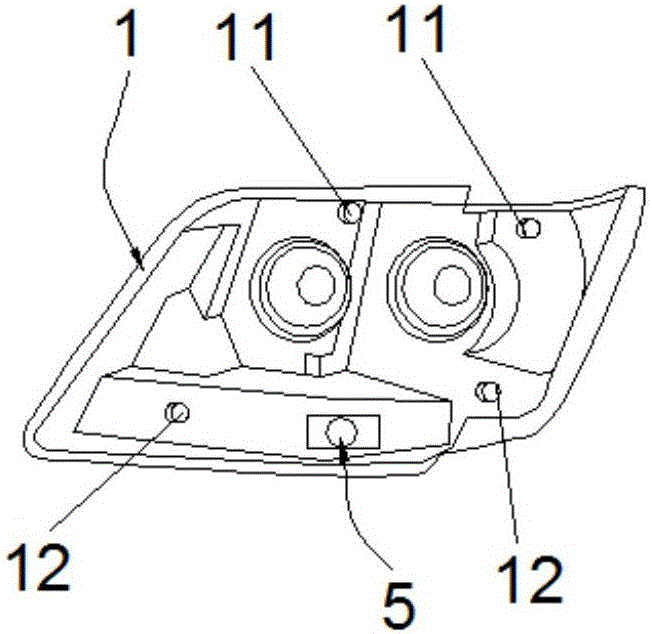

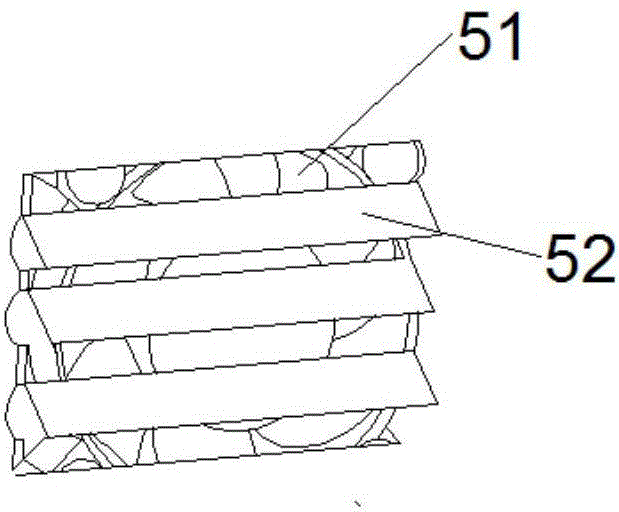

[0038] Such as figure 1 and figure 2 As shown, this embodiment provides a car lamp assembly, including a lamp housing 1, a reflector 2, a humidity sensor 4, a blower device 5, a controller 6, a car lamp and a light distribution mirror 3 connected to the lamp housing 1, A housing cavity is formed between the lamp housing 1 and the light distribution mirror 3, and the reflector 2, the humidity sensor 4, the blower device 5, the controller 6 and the car lights are all located in the housing cavity, and the reflector 2, the humidity sensor 4, the drum The wind device 5 , the controller 6 and the vehicle lamp are all fixed on the lamp housing 1 , and the humidity sensor 4 and the blower device 5 are electrically connected to the controller 6 .

[0039] When the automobile starts, the humidity sensor 4 arranged on the lamp housing 1 can accurately detect the humidity in the lamp assembly. When the humidity in the lamp assembly is higher than or equal to the set value of the humidi...

Embodiment 2

[0053] The present invention also provides a method for manufacturing the above-mentioned vehicle lamp assembly, comprising the following steps:

[0054] a. Sputter a layer of zinc oxide film on the inner surface of the clean reflector 2; for example: put the body of the clean reflector 2 into the sputtering chamber, and spray it on the inner surface of the clean reflector 2 Sputter a layer of zinc oxide film.

[0055] b. Open the exhaust hole 11 and the suction hole 12 on the lamp housing 1, and install the humidity sensor 4, the controller 6, the blowing device 5 and the heating device 7 on the lamp housing 1.

[0056] c. A connection groove for installing the light distribution mirror 3 is opened on the lamp housing 1, and the light distribution mirror 3 is clamped in the connection groove, and then glue is injected into the connection groove and solidified.

[0057] Compared with the prior art, the advantages of the automobile and the above-mentioned lamp assembly are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com