Spiral ash discharging machine

A technology of helical and helical blades, which is applied in the field of auxiliary equipment for biomass fuel power generation boilers, can solve problems such as the blockage of the discharge port and affect the ash discharge efficiency and ash discharge effect, and achieve the convenience of discharge, ensure the ash discharge effect, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

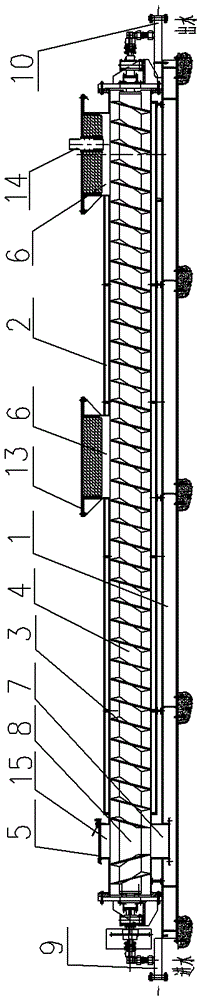

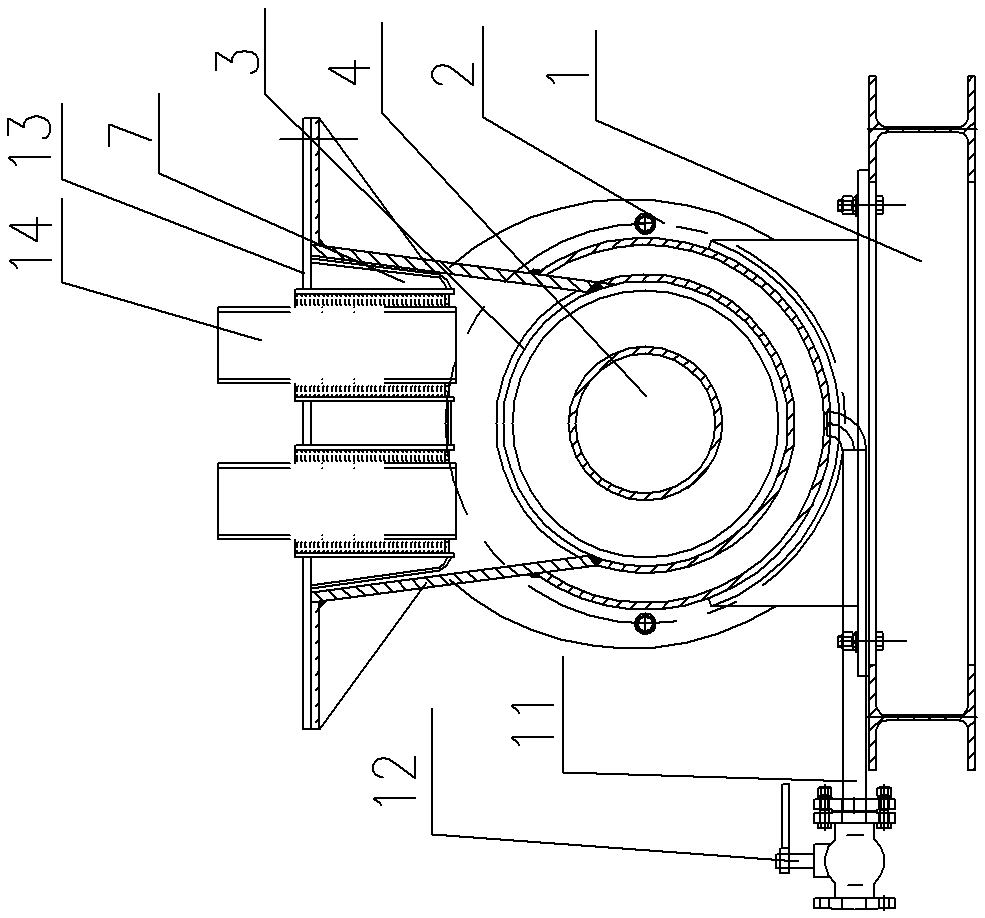

[0010] See figure 1 , figure 2 Shown, a kind of screw ash machine, it comprises base 1, and ash machine body 2 is installed on base 1, and ash machine body 2 comprises outer cylinder body, and the rotating shaft 4 with helical blade 3 is arranged in the outer cylinder body, The rotating shaft 4 is connected to the drive motor, and the upper part of the left end of the outer cylinder is provided with a feed port 6, and the lower part of the right end is provided with a discharge port 7, and the rotating shaft 4 corresponding to the discharge port 7 does not have a spiral blade 3 to form a polished rod segment 8, which is located on the polished rod The rotating shaft 4 on the right side of the section 8 is provided with forward spiral blades 3, and the rotating shaft 4 on the left side of the polished rod section 8 is provided with at least two sets of reverse spiral blades 3, and the rotating shaft 4 is provided with a water-cooling pipe. One end of the rotating shaft 4 is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap