Water-flow-variable air conditioner tail end and work method thereof

An air-conditioning terminal and working method technology, applied in air-conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of unbalanced water flow at the terminal, energy waste, insufficient comfort, etc., to ensure energy saving, ensure hydraulic balance, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

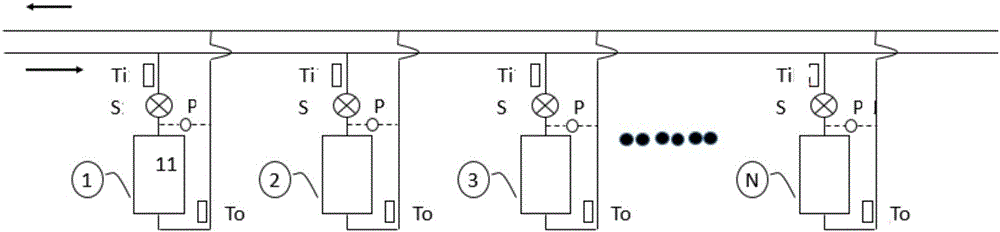

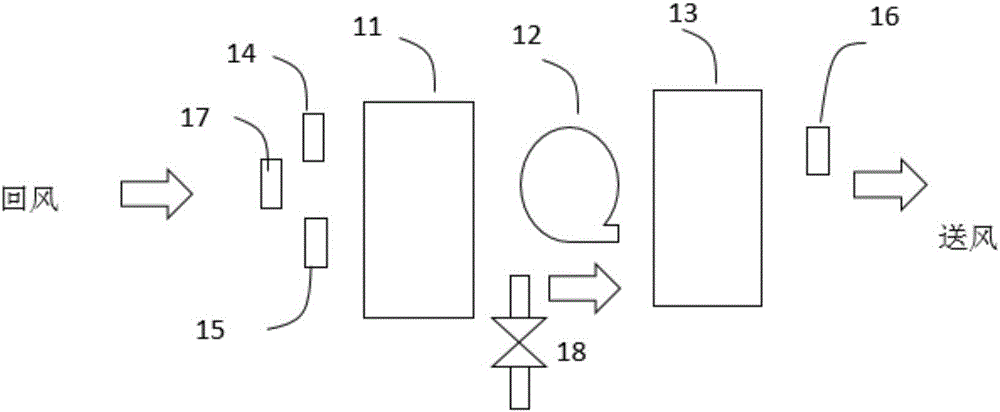

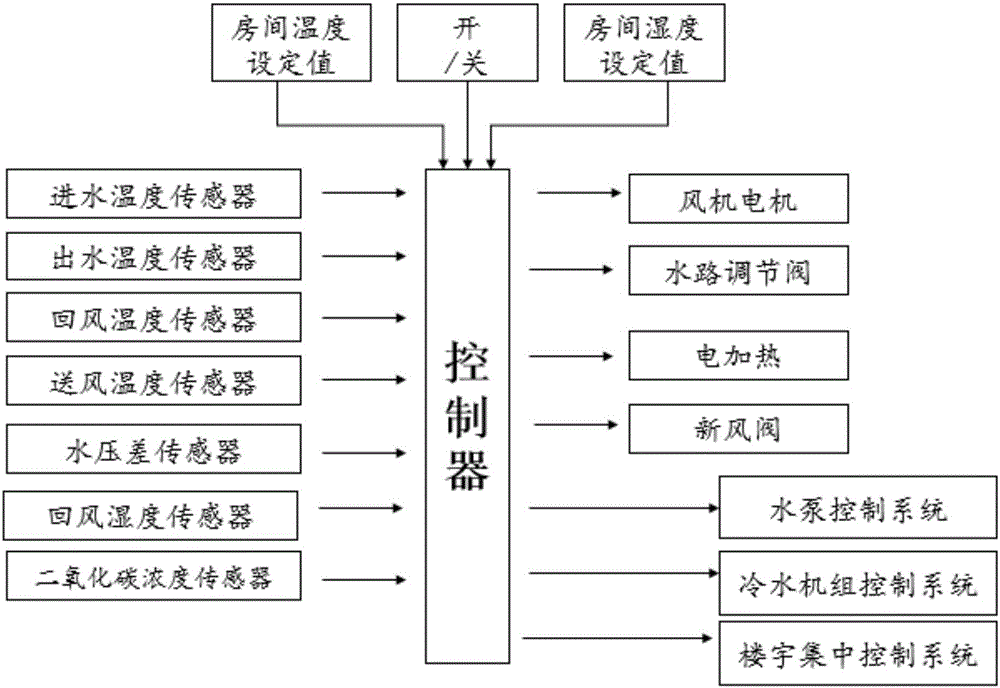

[0035] One air-conditioning terminal: the cooling capacity is 3kW, the rated flow rate is 8.6L / min, the pressure drop under the rated flow rate is 30kPa, the heating capacity is 3.6kW, and the electric heating power is 1kW. Each air-conditioning terminal includes: coil heat exchanger 11, water circuit Electromagnetic regulating valve S, inlet water temperature sensor Ti, outlet water temperature sensor To, differential pressure sensor P, controller, return air temperature sensor 14, outlet air temperature sensor 16, electric heating 13, fan 12, return air humidity sensor 15, carbon dioxide sensor 17. like figure 1As shown, in the direction of water flow, the water circuit electromagnetic regulating valve S is arranged before the coil heat exchanger 11, the inlet water temperature sensor Ti is arranged before the coil heat exchanger 11, and the outlet water temperature sensor To is arranged before the coil heat exchanger After 11, a differential pressure sensor P is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com