Automatic feed-grate linkage-mode coal hot air furnace

A linkage type and hot blast stove technology is applied in the field of coal-fired hot blast stoves and automatic coal-fired grate linkage type coal-fired hot blast stoves, which can solve the problems of workers being unable to rest normally, the temperature fluctuation is large, and the grate cannot be moved. Reliable performance, beneficial to combustion, and prevention of ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

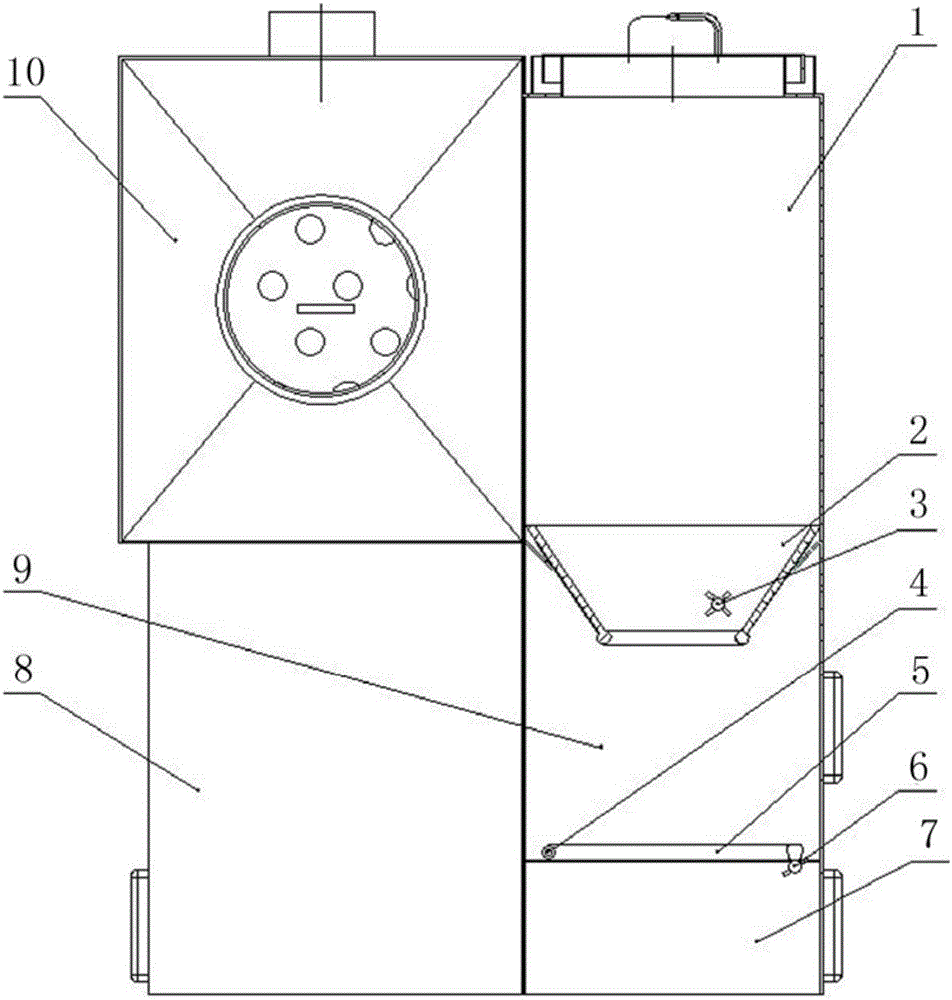

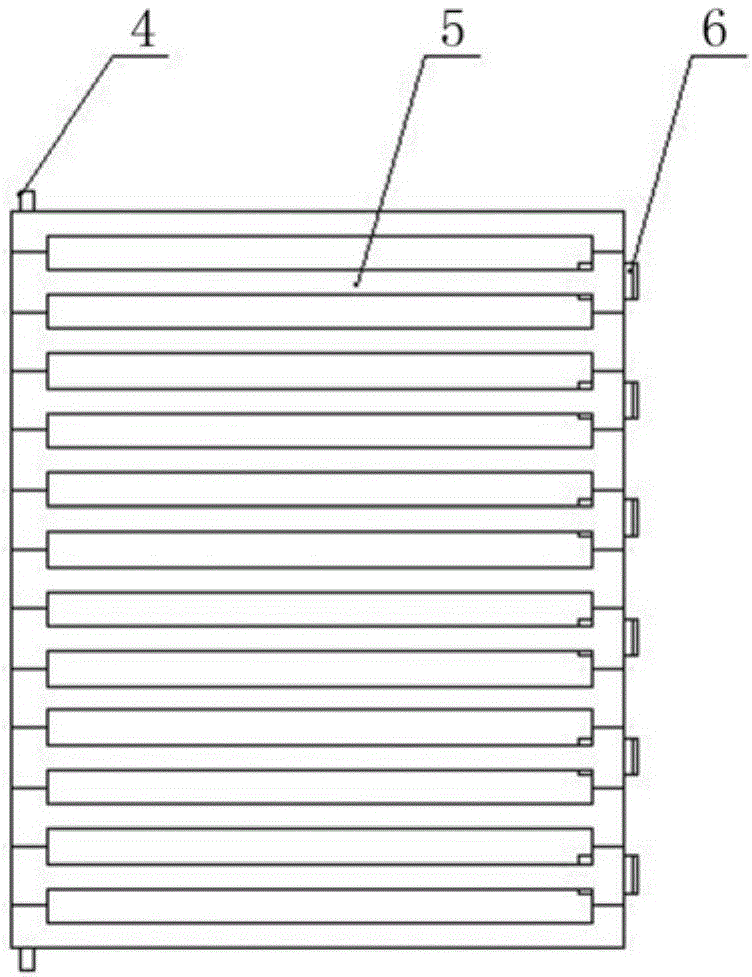

[0022] refer to figure 1 and figure 2 , the automatic coal grate linkage type coal-fired hot blast stove of the present invention includes: a combustion chamber 9, ash chamber 7, a secondary combustion chamber 8, a heat exchange chamber 10, a coal storage bin 1, a middle cavity coal drop hopper 2, an active Lower coal roller 3, fire grate fixed shaft 4, fire grate 5 and fire grate stirring roller 6.

[0023] The ash chamber 7 is located below the combustion chamber 9 , the secondary combustion chamber 8 is located on the side of the combustion chamber 9 , and the heat exchange chamber 10 is located above the secondary combustion chamber 8 . The unburned combustible gas in the combustion chamber 9 enters the secondary combustion chamber 8 for combustion, and the heat of combustion is transferred in the heat exchange chamber 10 and heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com