Cooling device of testing machine

A cooling device and testing machine technology, applied in cooling fluid circulation devices, household refrigeration devices, measuring devices, etc., can solve problems such as affecting equipment stability, unstable equipment oil pressure, and reducing the service life of lubricating oil and hydraulic oil, etc. To achieve the effect of reducing the involvement of impurities, facilitating heat dissipation and cooling, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

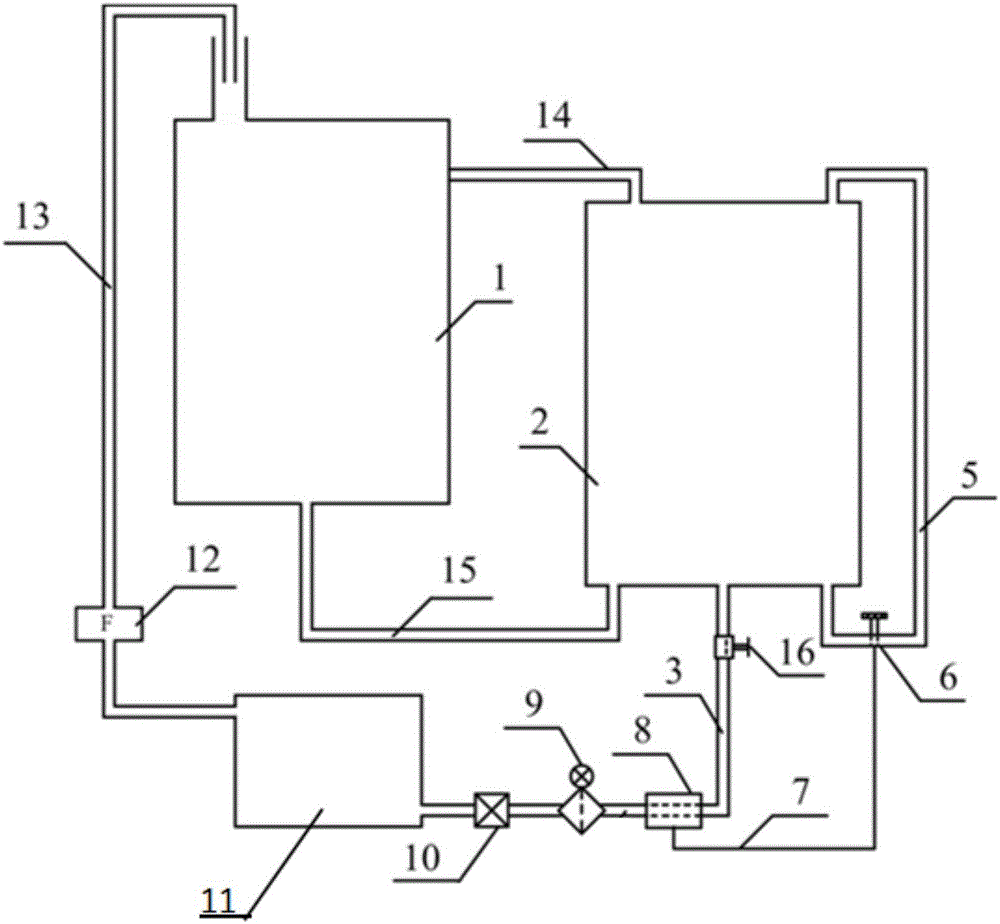

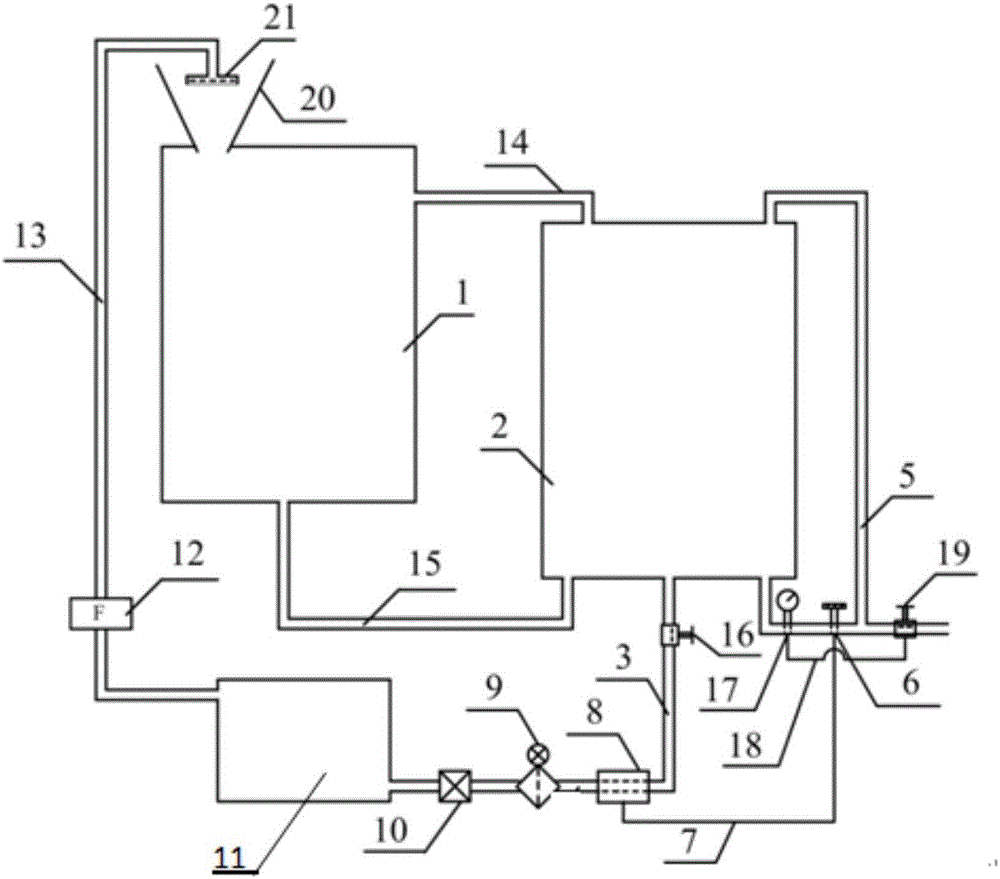

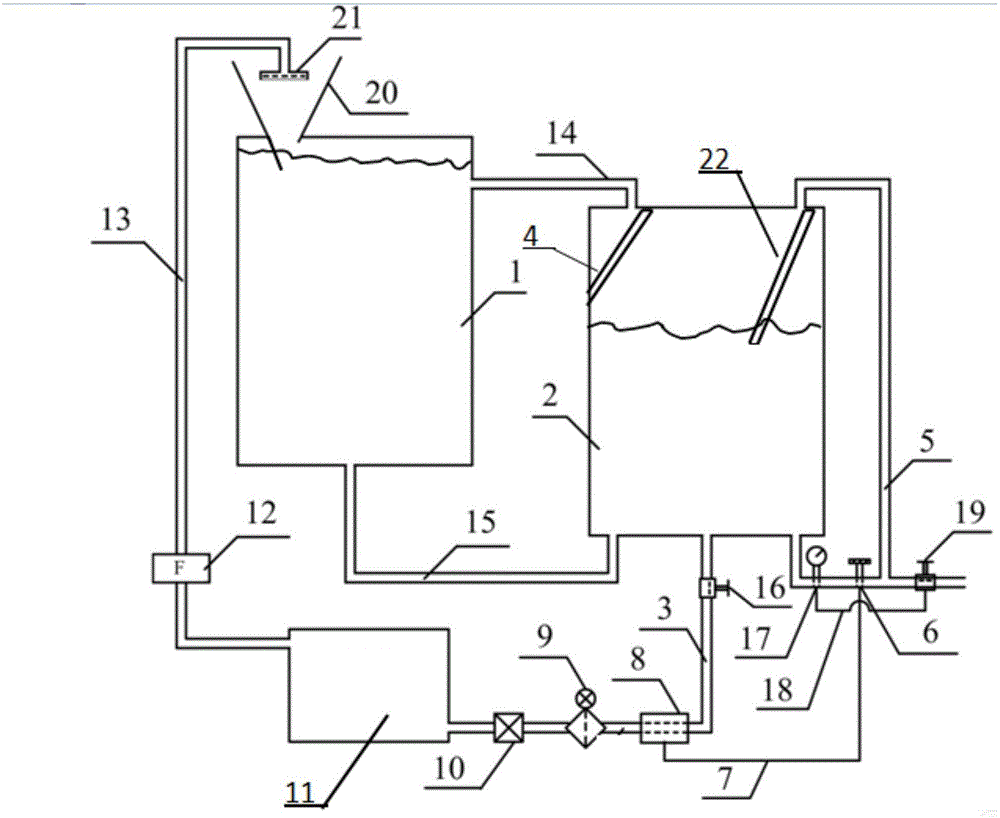

[0025] figure 1 An implementation form of the cooling device of the testing machine according to the present invention is shown, which includes:

[0026] The first water storage tank 1, which is a container with an upper opening, can dissipate heat to the relatively high-temperature cooling water in the upper layer;

[0027] The second water storage tank 2, which is a container with an upper opening, is placed in a gradient arrangement with the first water storage tank 1, and the position of the first water storage tank 1 is higher than the second water storage tank 2; the second water storage tank 2 The top of the top of the second water storage tank 1 communicates with the upper water level of the first water storage tank 1 through the second upper water pipe 14 to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com